Chemical Engineering

One of the branches in engineering is a chemical engineering, being the one applying the physical sciences as well as “life sciences”, such as biochemistry. Within this engineering study economics is included in terms of producing, transforming, transporting as well as use all chemicals and materials (and energy, if needed). Every chemical engineer is known to be working on designing the large-scale processes for converting raw materials, chemicals, living cells, energy and microorganisms into some useful products.

Chemical engineering emerged upon the so called “unit operations” development of chemical transformations and physical changes (crystallizations, separations, evaporations, polymerizations, filtrations, isomerization, etc.). Such unit operations are known to be a fundamental concept chemical engineering, being introduced into the course in 1905 by William Hultz Walker. Later, unit operations became one of the most important aspects of chemical engineering at many US universities as well as in London (Imperial College).

The AIChE (American Institute of Chemical Engineers) played a huge role in making chemical engineering to be considered as an independent science. It also made unit operations to be treated central in chemical engineering. Thus, it defined chemical engineering to be a science based on the so called “unit operations”. In this way, promoting the science of chemical engineering as a distinct science in Britain lead to establishing another institution in 1922 — the Institution of Chemical Engineers (IChemE), which helped to make the unit operations being considered essential within the discipline of the chemical engineering.

Later, it became clear that “unit operations” themselves were insufficient in developing the vessels developed for containing different chemical reactions — the chemical reactors. After, the so called “transport phenomena” became very popular, used for concerning the exchange of energy, mass, momentum, charge, and angular momentum between studied and observed systems, giving an analytical approach to chemical engineering science.

There have been many concerns about the safety as well as the environmental impact of chemical manufacturing facilities since 1962. The well-known “Flixborough disaster” took place in the United Kingdom in 1974 resulted in 28 deaths, also causing damage both to a chemical plant itself and the villages nearby. It happened on the 1st of June 1974, when an explosion at a chemical plant took place close to one of the villages in England – Flixborough in North Lincolnshire. After many other disasters, the IChemE required safety to be the main part of every course accredited since 1982.

Within a computer science you can always use all needed applications nowadays in order to design from a scratch as well as manage the plants, such as chemical ones. To simplify the calculations and the needed drawings there is no need left to do it all manually as there are many applications, such as ConceptDraw Pro exist, providing the useful tools for creating all needed schematics.

Working within chemical engineering science means sometimes being involved in the processes of managing the plants themselves as well as the conditions for ensuring the optimal plant operations. Most of the chemical reaction engineers are in charge for constructing the special models which can always be used within the design and reactor analysis. They use physical parameters and laboratory data for solving their problems and predicting the reactor performance. They may be responsible for creating the plans, conducting economic analyses and specification for new plants or for modifying the existing plants.

Such design engineers often design plants for meeting their clients' needs, being limited by a number of factors, such as safety standards, government regulations and, of course, the funding of such projects and so they depend of the investors for making the right decisions, who dictate the plants’ choice of process, equipment and materials. Plant construction is usually co-ordinated by “project managers” who all also depend on the investment.

All previously mentioned unit operations are used for purifying and separating the products of reactants as well as their preparing, controlling the energy transfer in the reactors within some particular project and recycling all unspent reactants. Any unit process is known to be simply the chemical equivalent of a “unit operation”, constituting the process operations. Some unit processes involve the conversion of material many means, such as thermochemical and biochemical.

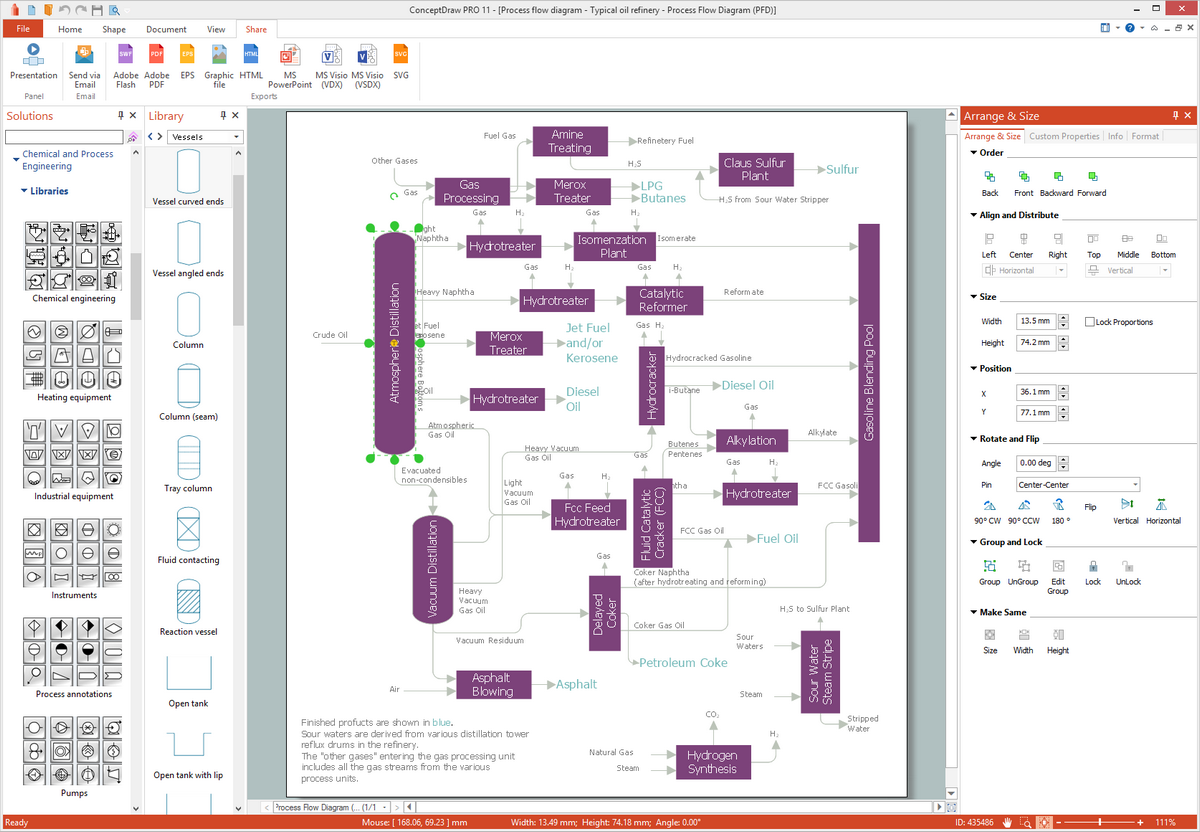

ConceptDraw DIAGRAM is a powerful diagramming and vector drawing software. Extended with Chemical and Process Engineering Solution from the Industrial Engineering Area of ConceptDraw Solution Park, it became the best Chemical Engineering software.

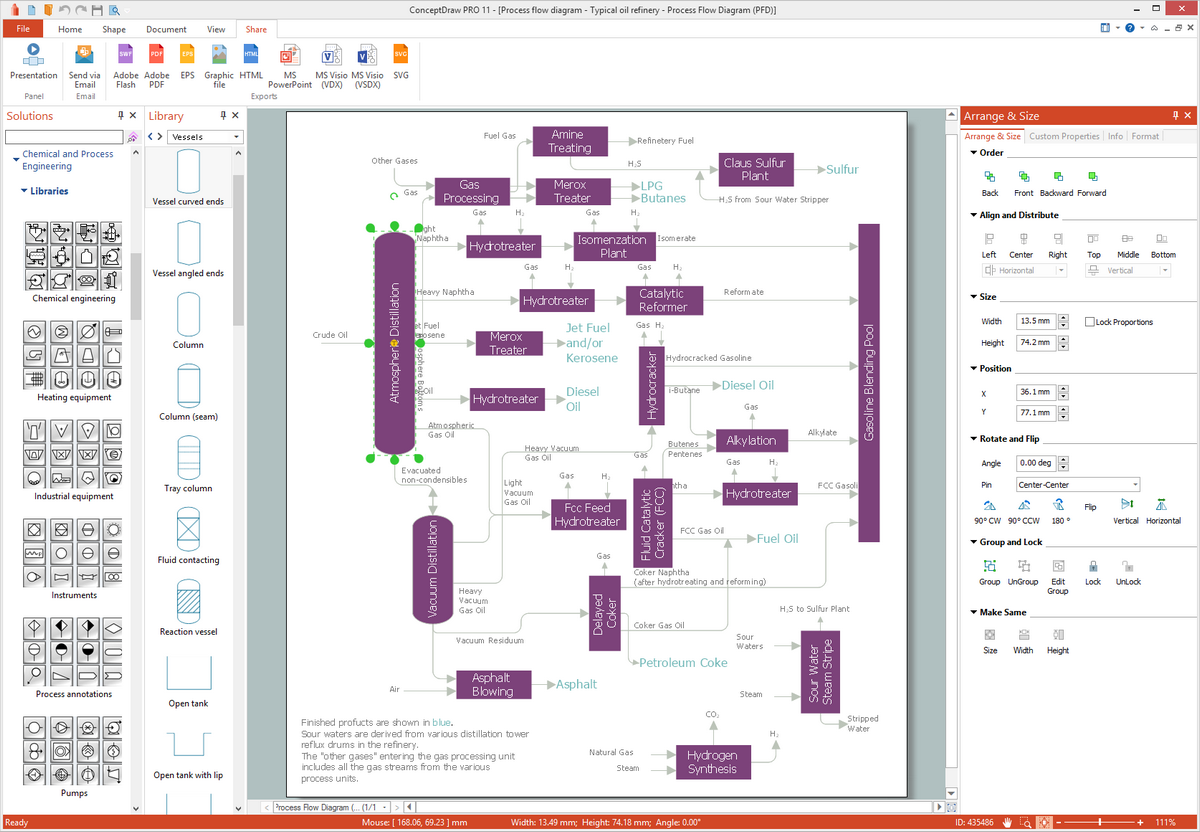

Example 1. Chemical Engineering in ConceptDraw DIAGRAM

Chemical and Process Engineering Solution greatly facilitates the design process of various chemical engineering diagrams, schemes, and illustrations.

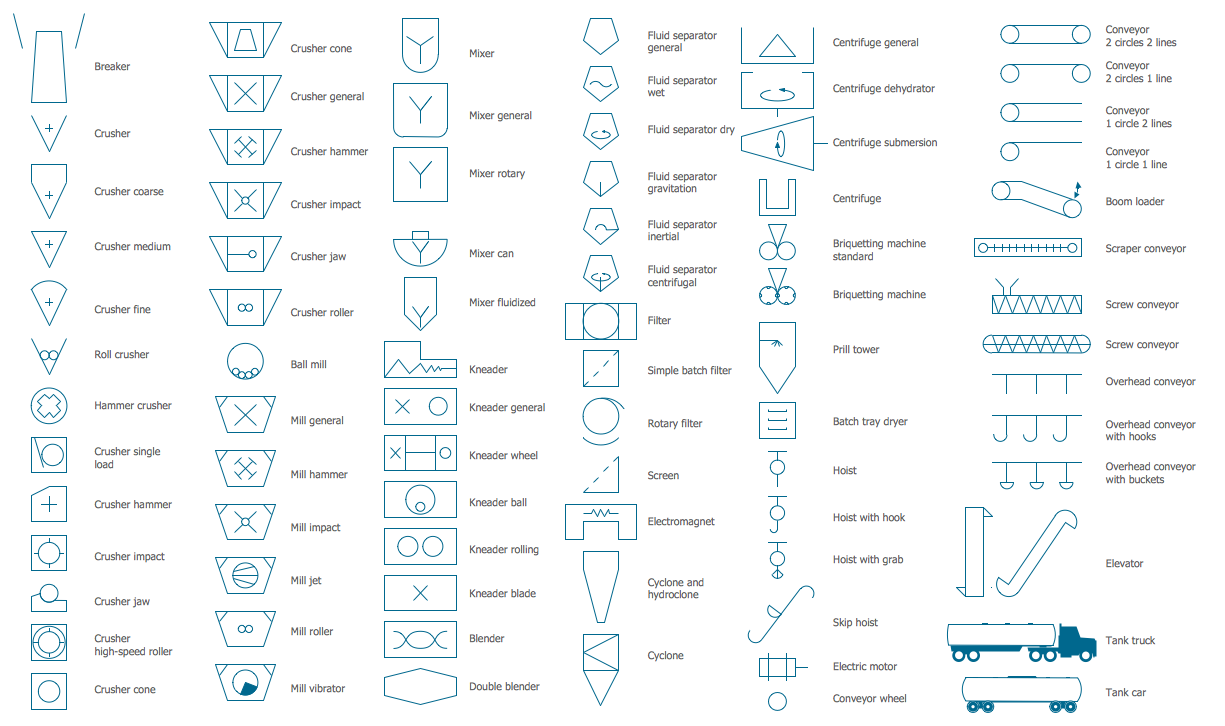

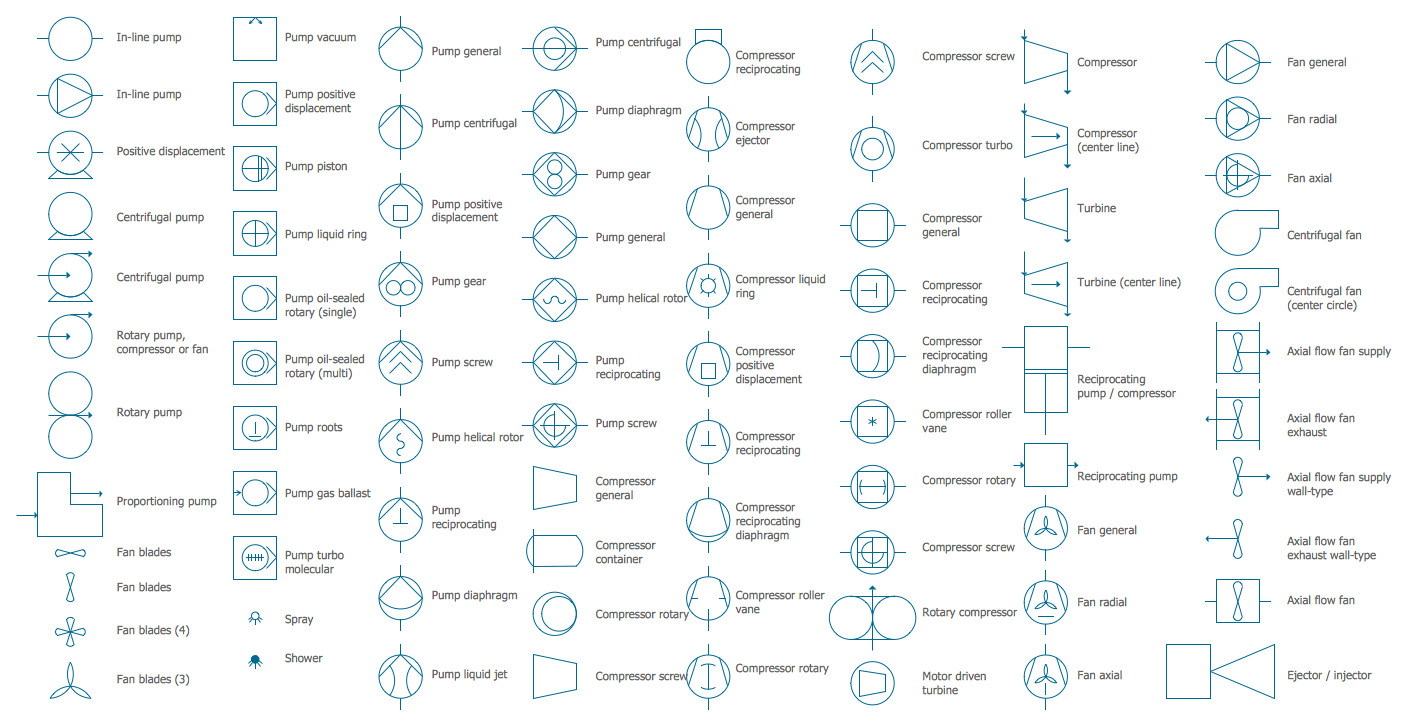

In order to design a process, you need to define the equipment sizes and types, finding out the way they are connected to each other. You also have to figure out all the available materials of construction. For such purposes, you might need a “process flow diagram” to be created, which can be done within ConceptDraw DIAGRAM software for only a few hours. Although, having ConceptDraw STORE application will lead to enabling you to do it even sooner, within only an hour or so as the mentioned application was developed especially for the ConceptDraw DIAGRAM users in order to simplify their processes of drawing only great looking schemes, such as plans and diagrams, charts, graphs, flowcharts and maps.

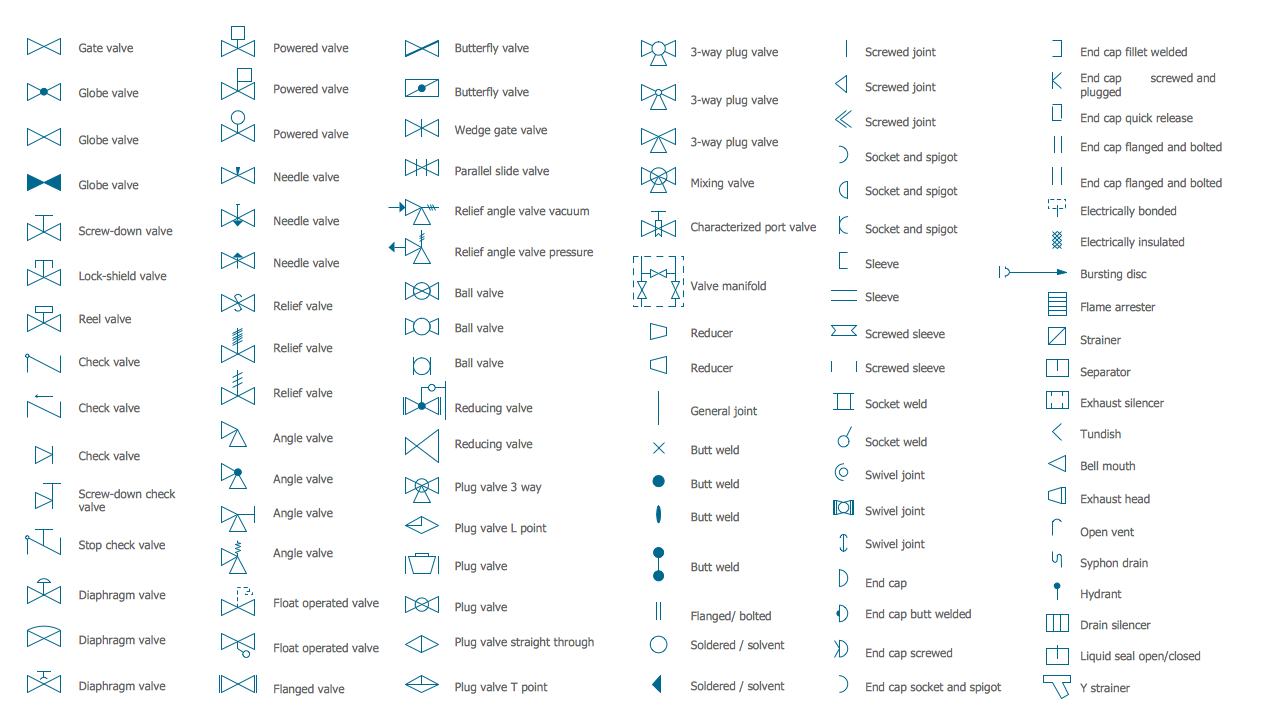

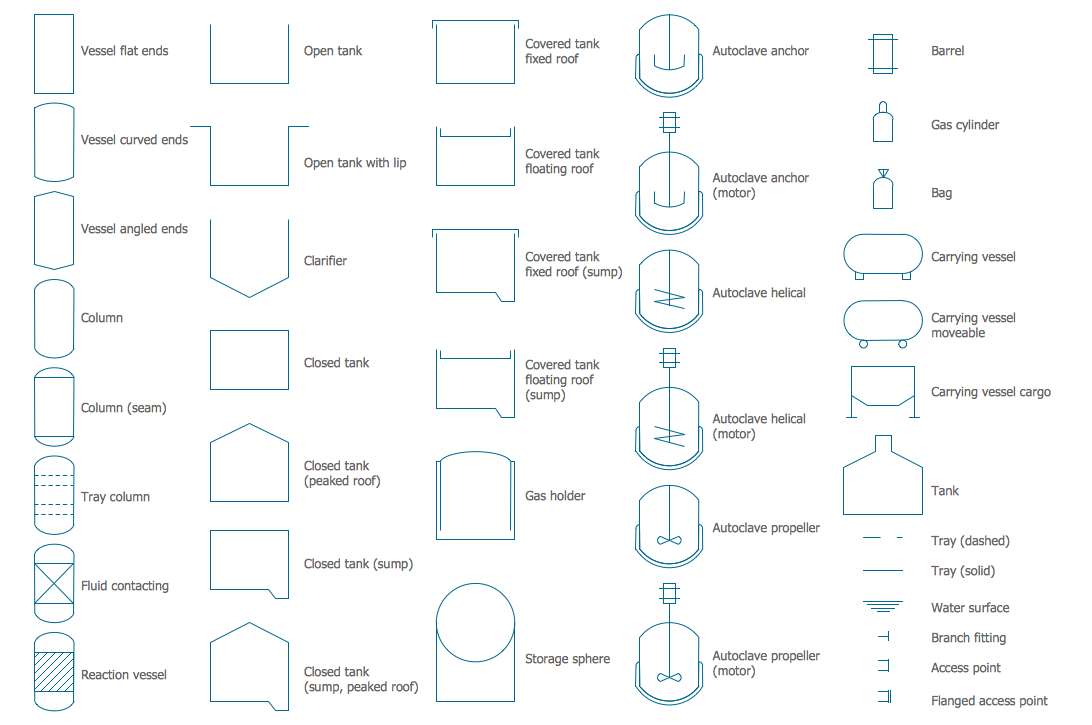

Thus, Chemical and Process Engineering Solution is the one providing many different stencil libraries, such as Chemical Engineering one, Heating Equipment one, Industrial Equipment one, Instruments one, Process Annotations one, Pumps Library, Valves and Fittings and the Vessels Library, which all can be used by any ConceptDraw DIAGRAM users any time they need all the professionally designed stencils from this solution.

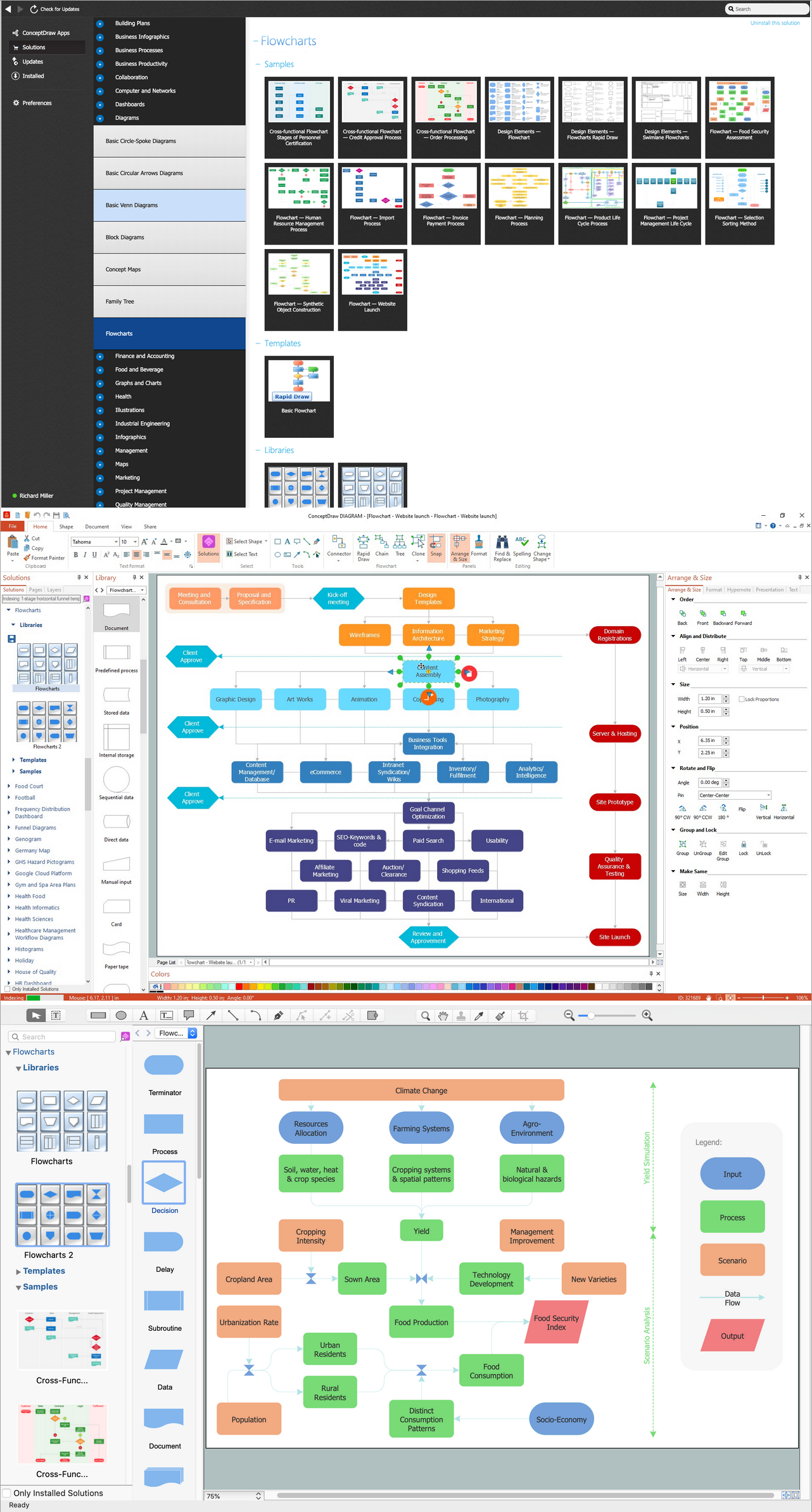

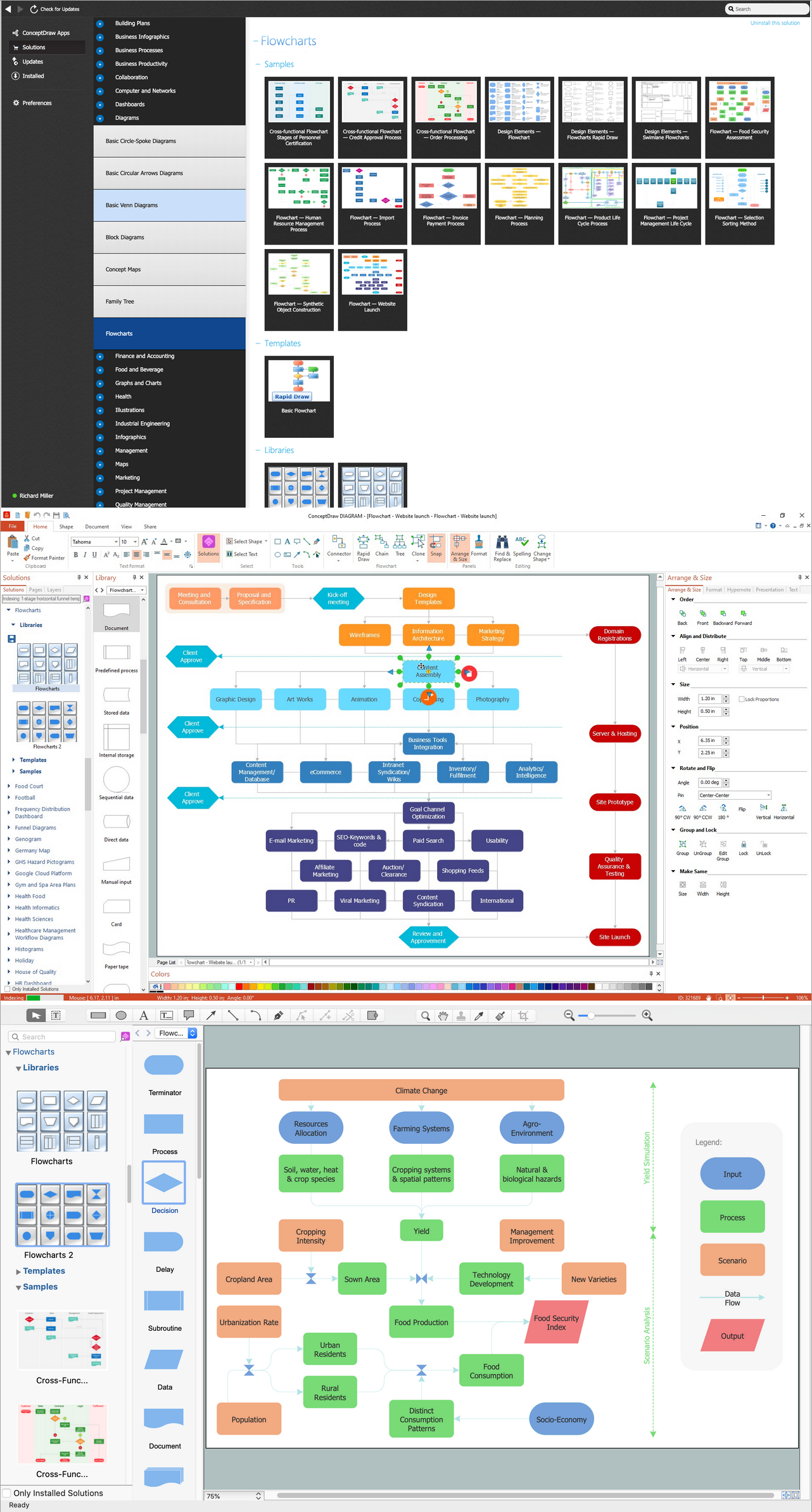

Example 2. Chemical and Process Engineering Solution in ConceptDraw STORE

Chemical and Process Engineering Solution includes also the set of samples and templates offered in ConceptDraw STORE.

Example 3. Chemical Engineering - Amine Treating Unit Schematic Diagram

The following features make ConceptDraw DIAGRAM the best Chemical Engineering software:

- You don't need to be an artist to draw professional looking diagrams in a few minutes.

- Large quantity of ready-to-use vector objects makes your drawing diagrams quick and easy.

- Great number of predesigned templates and samples give you the good start for your own diagrams.

- ConceptDraw DIAGRAM provides you the possibility to use the grid, rules and guides. You can easily rotate, group, align, arrange the objects, use different fonts and colors to make your diagram exceptionally looking.

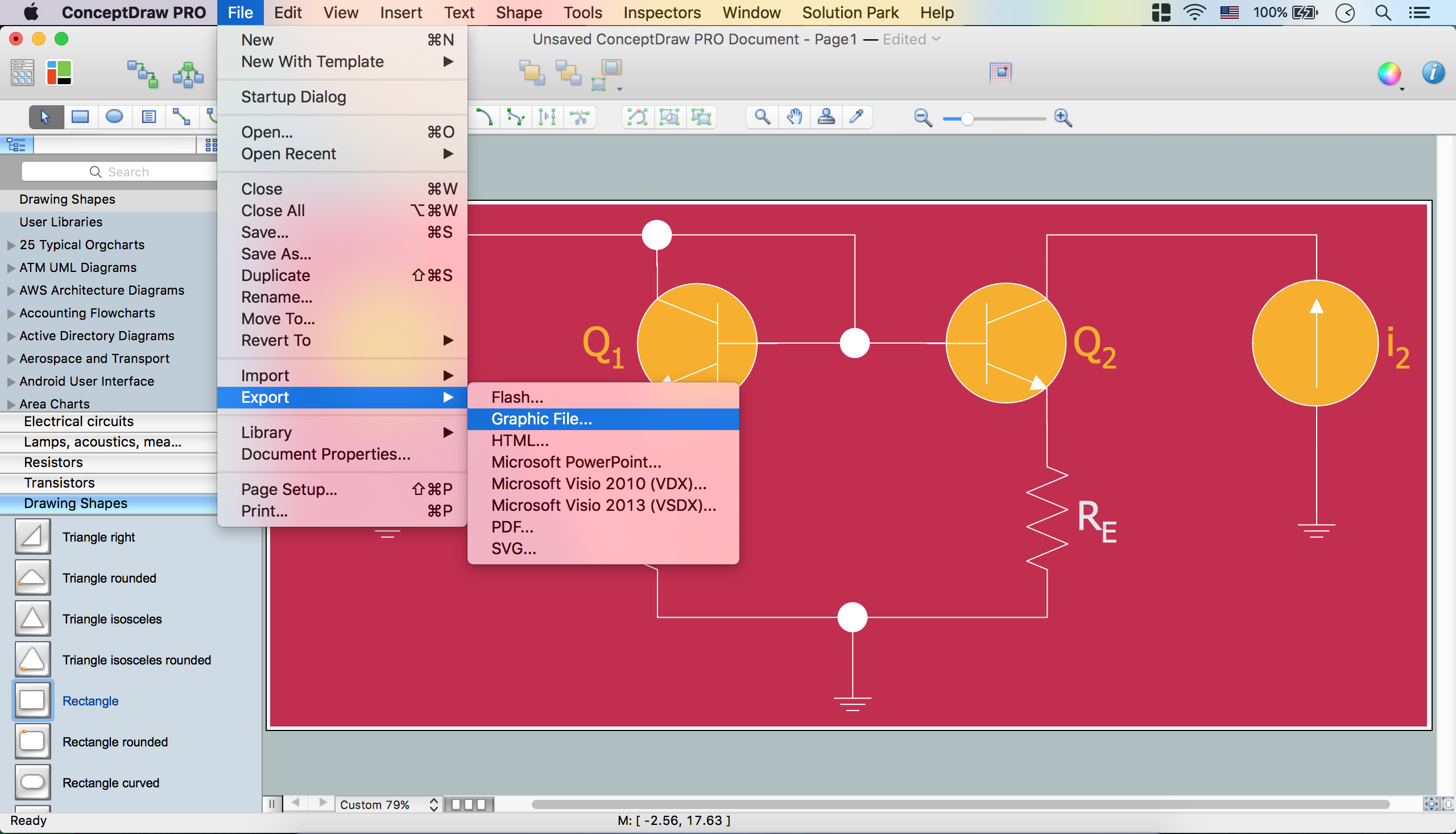

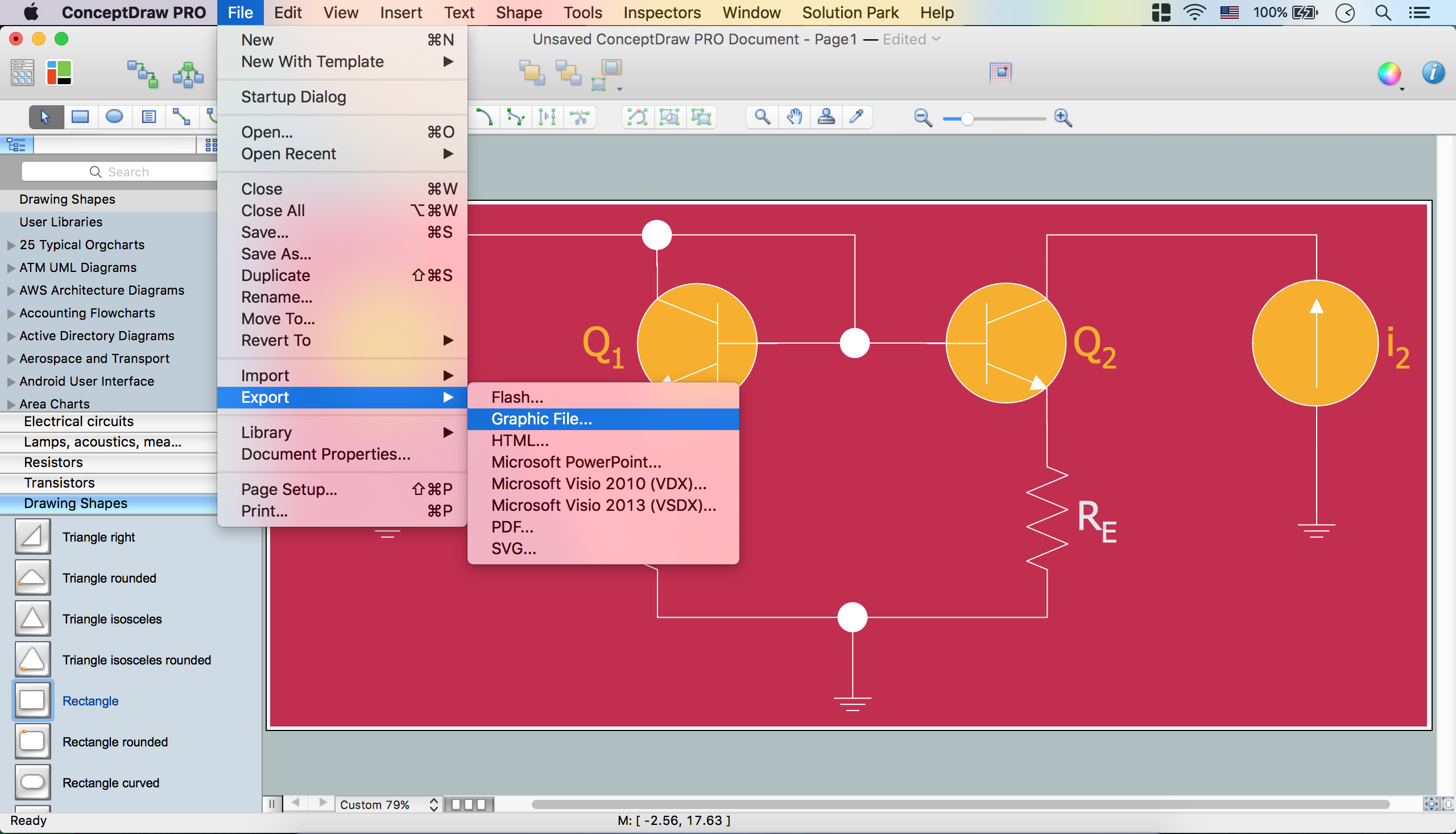

- All ConceptDraw DIAGRAM documents are vector graphic files and are available for reviewing, modifying, and converting to a variety of formats: image, HTML, PDF file, MS PowerPoint Presentation, Adobe Flash, MS Visio.

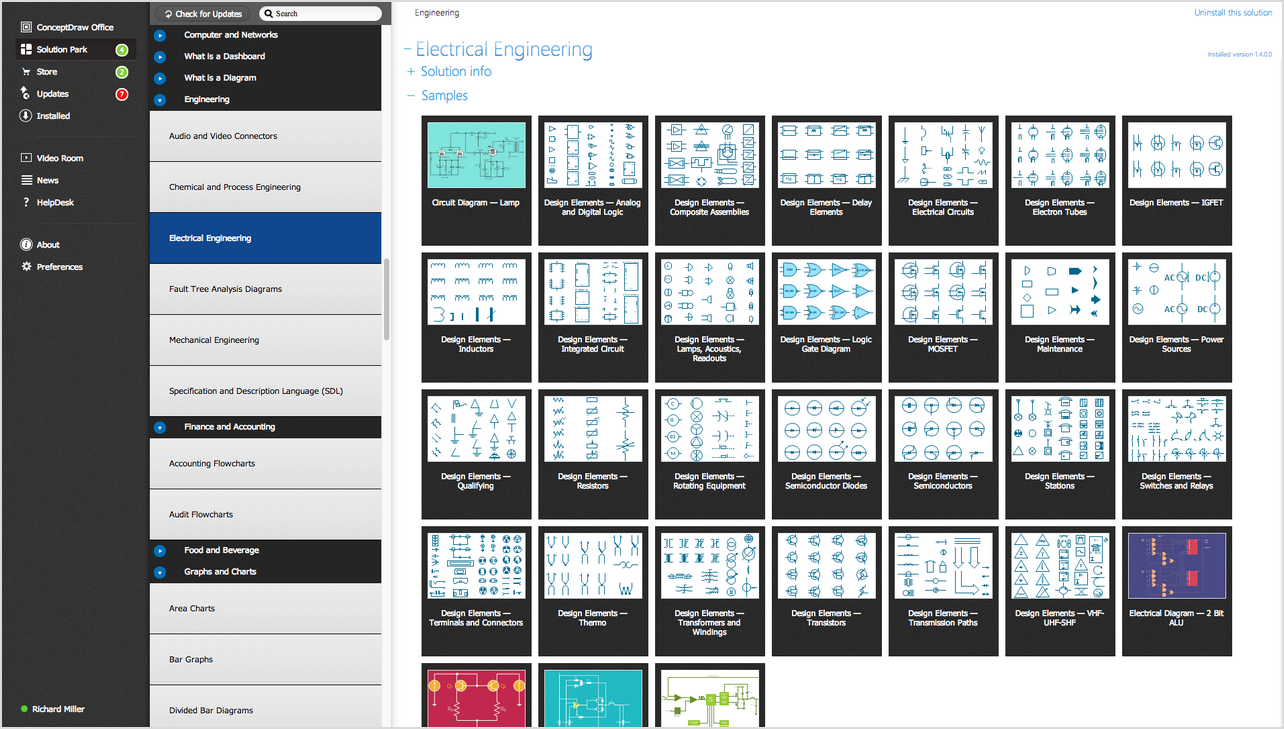

- Using ConceptDraw STORE you can navigate through ConceptDraw Solution Park, managing downloads and updates. You can access libraries, templates and samples directly from the ConceptDraw STORE.

- If you have any questions, our free of charge support is always ready to come to your aid.

TEN RELATED HOW TO's:

While creating flowcharts and process flow diagrams, you should use special objects to define different statements, so anyone aware of flowcharts can get your scheme right. There is a short and an extended list of basic flowchart symbols and their meaning. Basic flowchart symbols include terminator objects, rectangles for describing steps of a process, diamonds representing appearing conditions and questions and parallelograms to show incoming data.

This diagram gives a general review of the standard symbols that are used when creating flowcharts and process flow diagrams. The practice of using a set of standard flowchart symbols was admitted in order to make flowcharts and other process flow diagrams created by any person properly understandable by other people. The flowchart symbols depict different kinds of actions and phases in a process. The sequence of the actions, and the relationships between them are shown by special lines and arrows. There are a large number of flowchart symbols. Which of them can be used in the particular diagram depends on its type. For instance, some symbols used in data flow diagrams usually are not used in the process flowcharts. Business process system use exactly these flowchart symbols.

Picture: Basic of Flowchart: Meaning and Symbols

Related Solution:

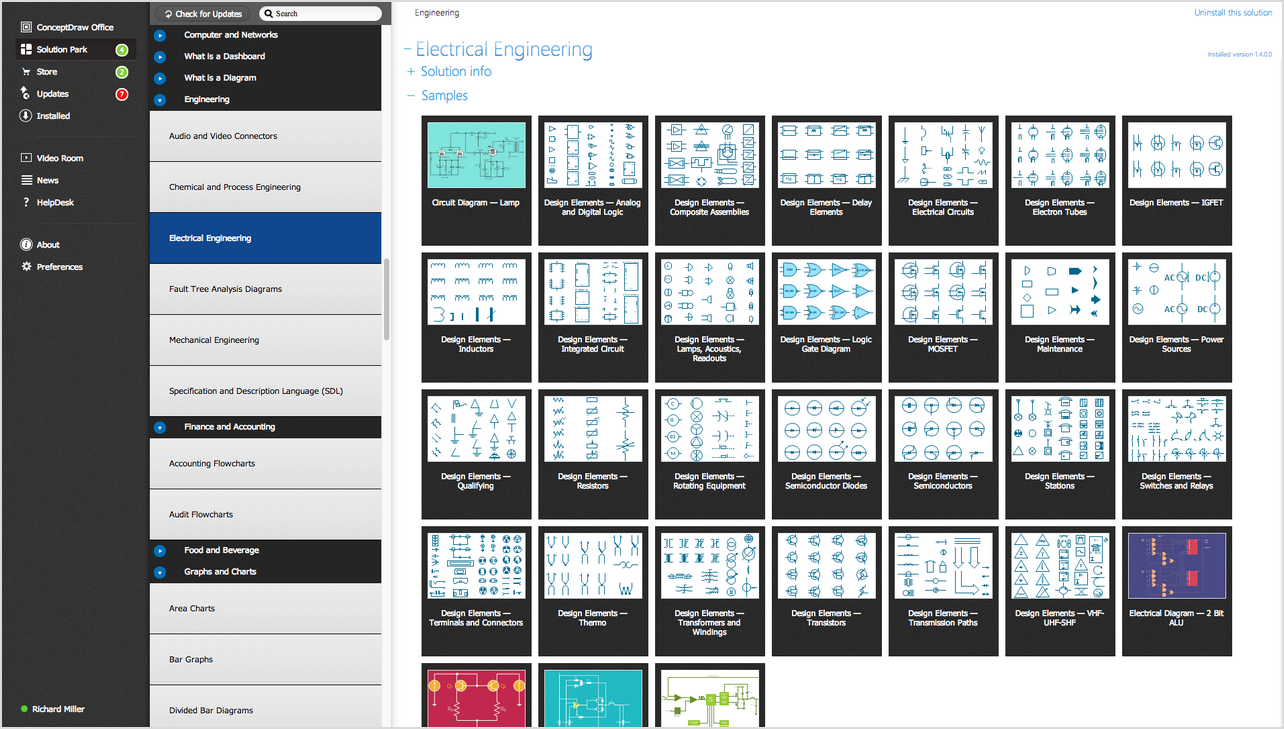

Electrical Engineering Solution used together with ConceptDraw DIAGRAM drawing facilities makes short a work of drawing various electrical and electronic circuit schemes. A library of vector objects composed from symbols of Analog and Digital Logic elements of electric circuit includes 40 symbolic images of logic gates, bistable switches of bi-stable electric current, circuit controllers, amplifiers, regulators, generators, etc. All of them can be applied in electronic circuit schemes for showing both analog and digital elements of the circuit.

Electrical Engineering Solution used together with ConceptDraw DIAGRAM drawing facilities makes short a work of drawing various electrical and electronic circuit schemes. A library of vector objects composed from symbols of Analog and Digital Logic elements of electric circuit includes 40 symbolic images of logic gates, bistable switches of bi-stable electric current, circuit controllers, amplifiers, regulators, generators, etc. All of them can be applied in electronic circuit schemes for showing both analog and digital elements of the circuit.

Picture:

Electrical Diagram Symbols F.A.Q.

How to Use Electrical ConceptDraw Diagram Software

Related Solution:

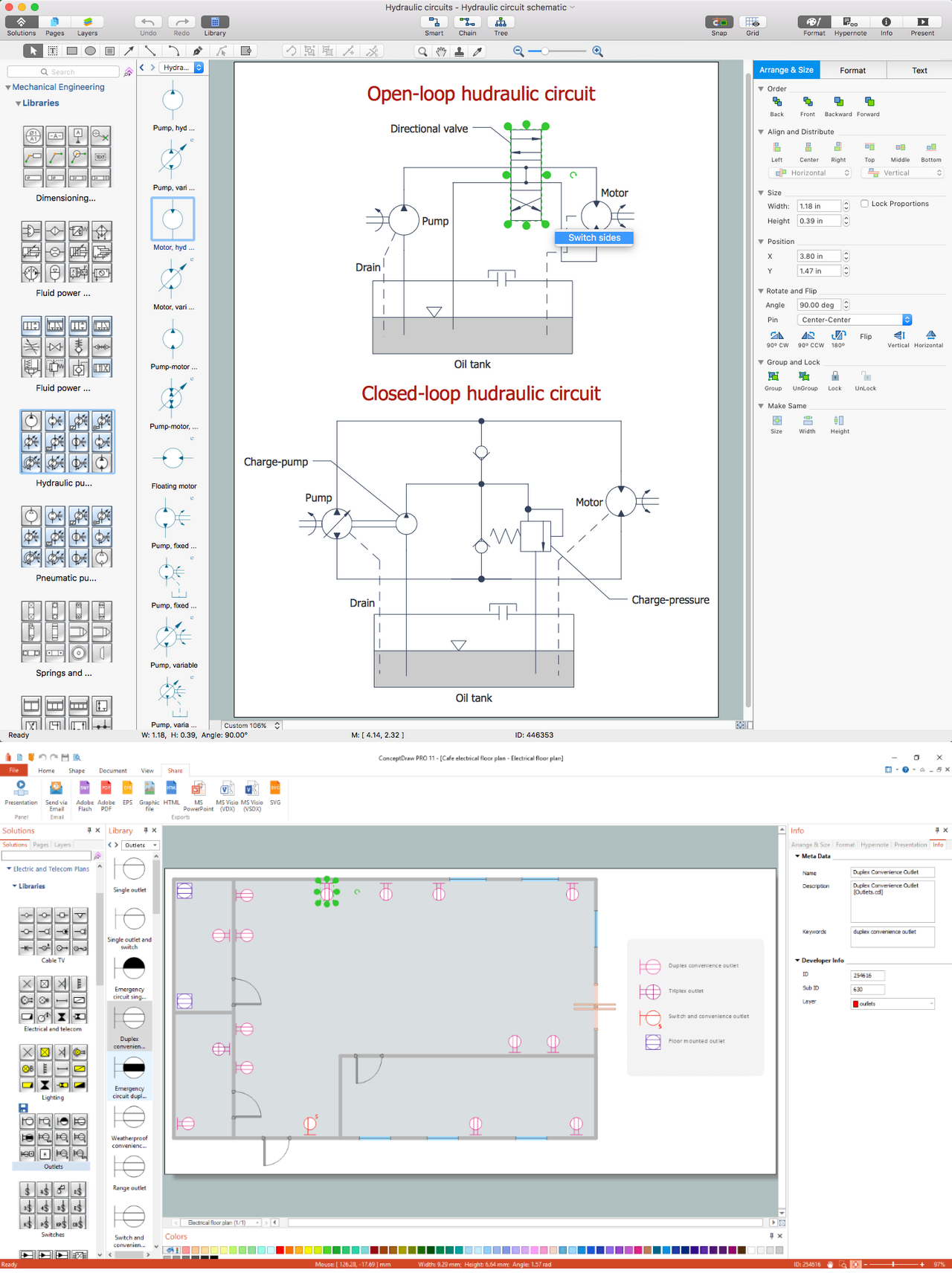

Electrical plan is a document that is developed during the first stage of the building design. This scheme is composed of conventional images or symbols of components that operate by means of electric energy. To simplify the creation of these schemes you can use house electrical plan software, which will not require a long additional training to understand how to use it. You only need to install the necessary software ant it’s libraries and you’ll have one less problem during the building projection.

Any building contains a number of electrical systems, including switches, fixtures, outlets and other lightening equipment. All these should be depicted in a building electrical plans and included to general building documentation. This home electrical plan displays electrical and telecommunication devices placed to a home floor plan. On the plan, each electrical device is referenced with the proper symbol. Electrical symbols are used for universal recognition of the building plan by different persons who will be working on the construction. Not all possible electric symbols used on a certain plan, so the symbols used in the current home plan are included to a legend. The electrical home plan may be added as a separate document to a complete set of building plans.

Picture: How To use House Electrical Plan Software

Related Solution:

Beginning from the 19th century, people tried to tame electricity. Nowadays, electrical engineering covers a wide range of applications starting from providing illumination in our homes to developing space technologies. Considering the fact that every project needs documentation, engineers use electrical diagram software to develop these projects. Standard electrical symbols of electrical components are recognizable all around the world.

This illustration represents the 26 libraries that are supplied by the ConceptDraw Electrical Engineering solution. The Electric Engineering libraries contains about a thousand objects enabling you to draw various charts depicting electrical connections and circuits, along with schemes of different equipment and devices. The electric engineering libraries delivered with ConceptDraw solution meet the standards adopted in the image to electrical circuits. So they can be used by professionals along with amateurs in electrical engineering.

Picture: Electrical Diagram Software

Related Solution:

ConceptDraw DIAGRAM extended with IDEF0 Diagrams solution from the Software Development area of ConceptDraw Solution Park is a powerful diagramming and vector drawing IDEF0 software. All IDEF0 diagrams created in ConceptDraw DIAGRAM are vector graphic documents and can be reviewed, modified and converted to MS Visio XML format. To obtain the IDEF0 Visio documents from ConceptDraw DIAGRAM documents use the wide export possibilities of ConceptDraw DIAGRAM.

Picture: IDEF0 Visio

Related Solution:

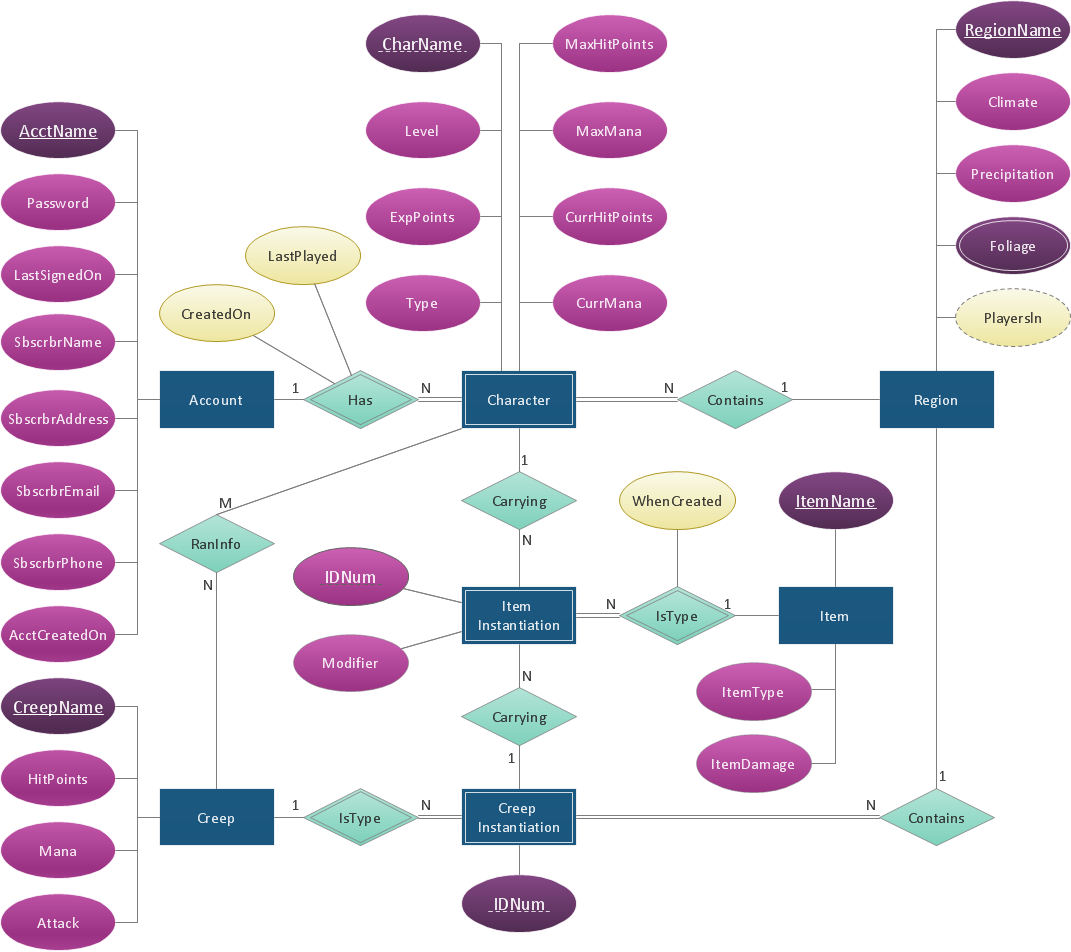

Database design is an important part of any project, as databases become more and more complex nowadays. To make the model more representative, entity relationship diagrams are widely used in software engineering area. These diagrams show sets of entities as rectangles connected via lines labeled with their cardinalities.

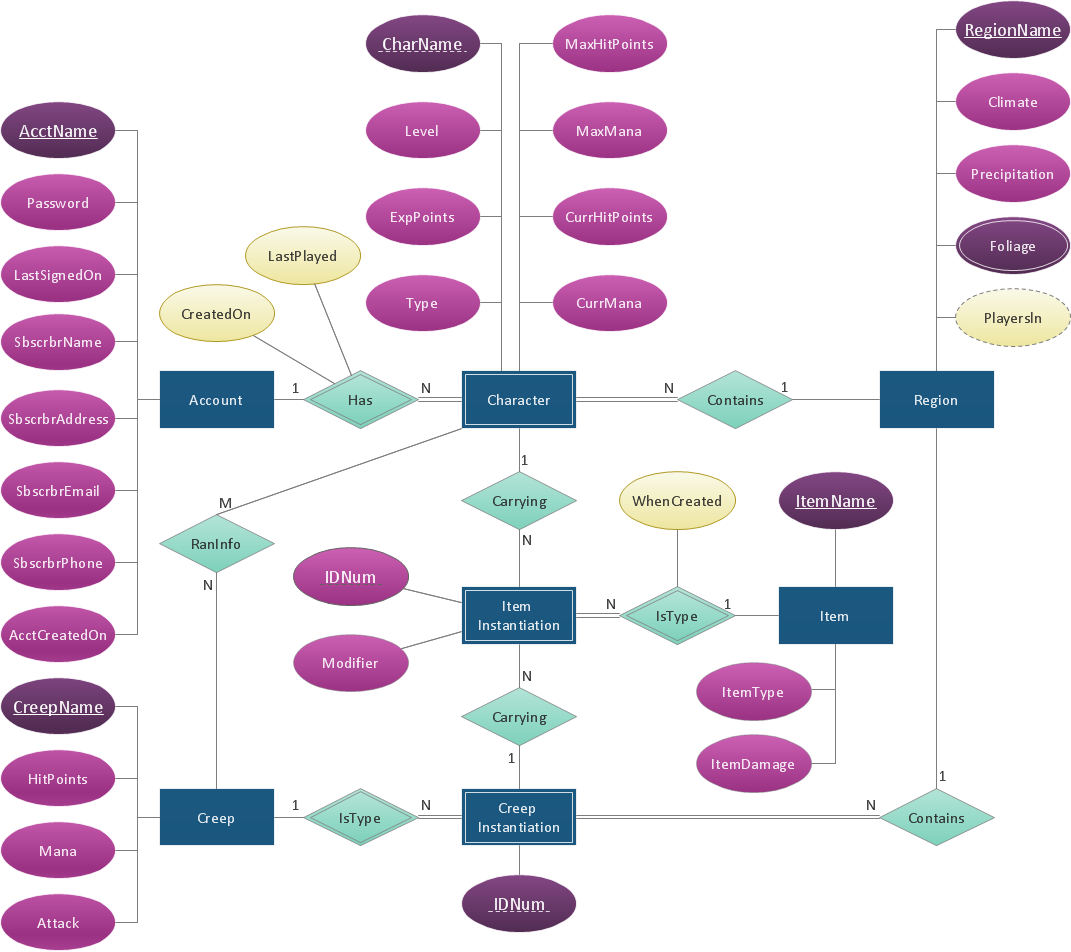

This an example of the ER-diagram developed to store information regarding some online role-playing game. It includes three main elements of ER diagram: entities, relationships and attributes. The entities, attributes and relationships on this ER-diagram is depicted according to the Chen's notation. Chen's notation for Entity Relationship diagrams admits using of rectangles to depict entities, ovals for attributes and ,at least, diamonds to show relationships. ConceptDraw Entity-Relationship Diagrams solution was applied as ERD software to create this diagram.

Picture: ConceptDraw DIAGRAM ER Diagram Tool

Related Solution:

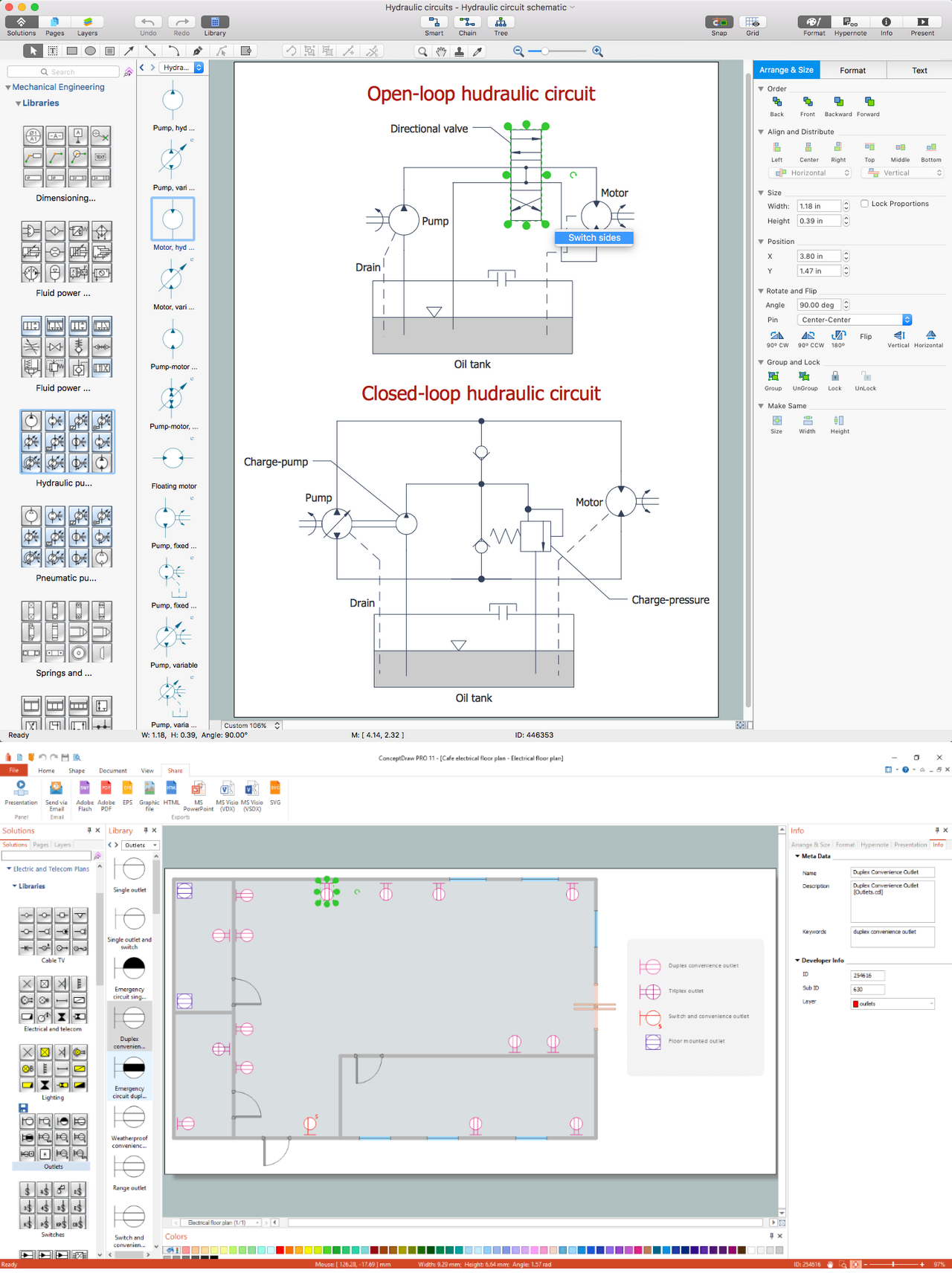

This diagram represents the electrical floor plan. This is a common practice - to draw the electrical plan on the floor plan. The outlets, fixtures and other electrical equipment are depicted on the floor plan with special symbols. This drawing was created using the possibilities of ConceptDraw DIAGRAM as CAD software. Computer-aided design software is intended to replaces manual engineering drafting with an automated process. CAD software is used by engineers, architects, and others to make high-precision technical drawings and illustrations. CAD software allows technical specialists to develop, examine and manage various engineering projects.

It is almost impossible nowadays to imagine mechanical engineering without digital technologies. Finding a suitable CAD software for creating mechanic diagram and electrical diagram architectural designs can take a lot of time and effort. However, with ConceptDraw DIAGRAM you can create any diagram that you want and later convert it to the most popular graphic formats like.vsdx,.png,.pptx etc.

Picture: CAD Drawing Software for Making Mechanic Diagram and Electrical Diagram Architectural Designs

Related Solution:

This sample shows the Flowchart that displays the layout and work flow of the cloud marketing platform. This diagram has a style of the marketing brochure. This style displays the central product that is related to the other issues.

Using the ready-to-use predesigned objects, samples and templates from the Flowcharts Solution for ConceptDraw DIAGRAM you can create your own professional looking Flowchart Diagrams quick and easy.

Picture: Flowchart Marketing Process. Flowchart Examples

Related Solution:

Create your own flow charts of computer or network system account processing using the ConceptDraw DIAGRAM.

Picture:

Account Flowchart

Flowchart Examples

Related Solution: