Quality Control

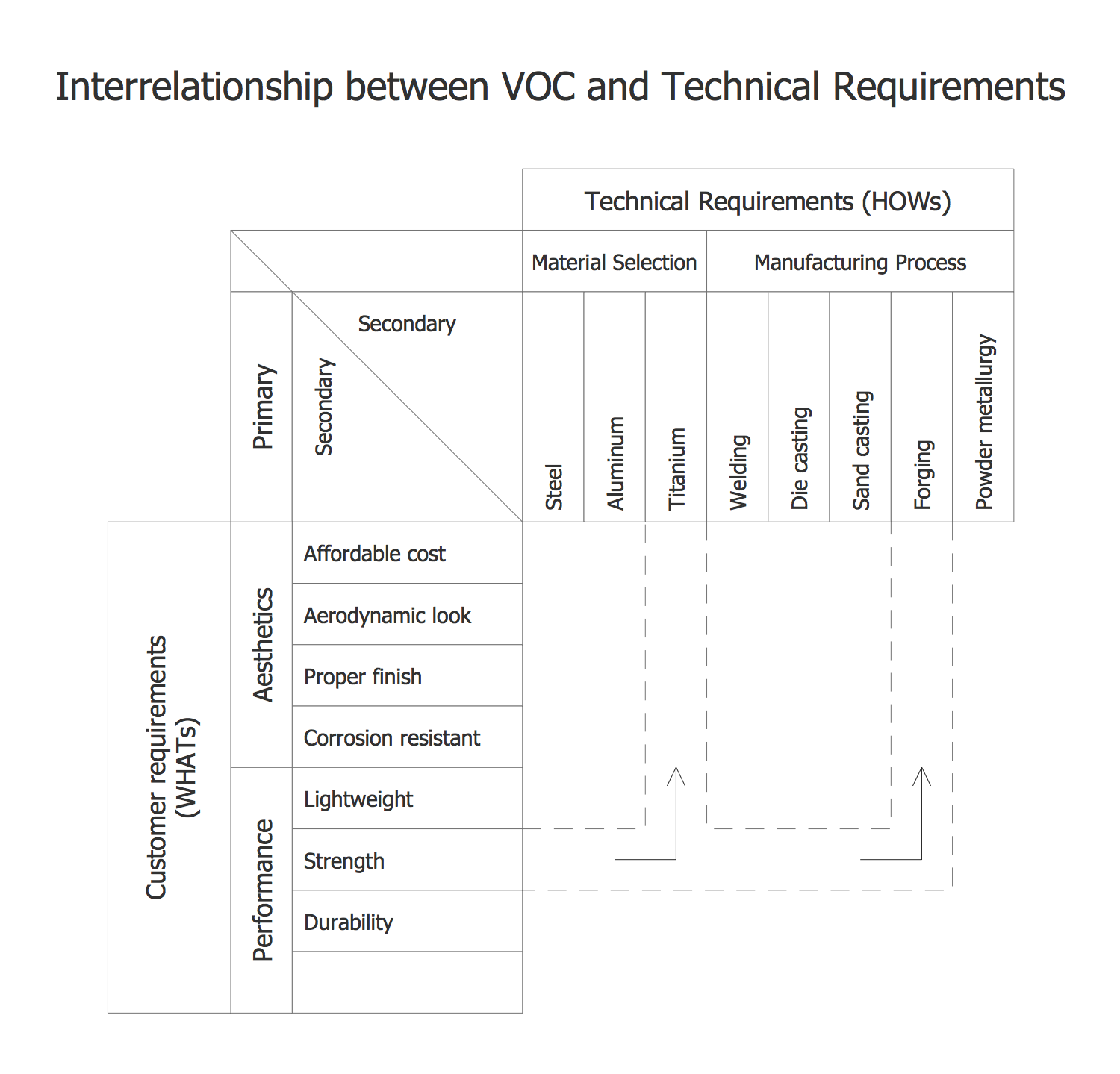

In case some task should be completed within a short period of time, ConceptDraw STORE application is the right application to use as another product of CS Odessa that was developed especially for a reason of helping all the ConceptDraw DIAGRAM users make all the needed drawings on time by providing the so-called “solutions”, such as the House of Quality one, which allows using the pre-made templates of the HOQ diagrams and HOQ matrices.

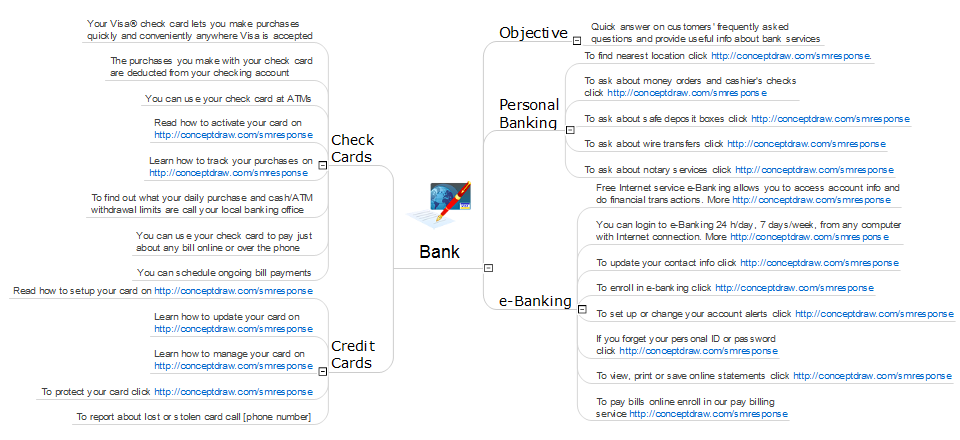

Pic. 1. House of Quality VOC vs Technical Requirements

Apart from two mentioned tools, there is also a ConceptDraw MINDMAP software that can be also downloaded from this site. Working with quality control problems, the previously mentioned applications can be very useful in terms of providing you with the needed tools, such as stencil libraries full of design elements and pre-made templates that can be all used as drafts for other, unique-looking drawings.

Being a process by which different entities can review the quality of all factors that may be involved in the production, quality control is defined in the ISO 9000 standard as one of the parts of quality management that are focused on fulfilling all the needed quality requirements.

The mentioned approach is known to be placing an emphasis on the following aspects: elements (such as job management, controls, defined and well managed processes, identification of records, integrity and performance criteria), competence (e.g., skills, knowledge, experience, qualifications), soft elements (personnel, confidence, integrity, organizational culture, quality relationships, motivation and team spirit) and infrastructure.

Inspection is known to be a major component of any quality control processes where a physical product can be examined in a visual way. All the product inspectors can be provided with the necessary descriptions and lists of the unacceptable product defects (surface blemishes or cracks, for example). As all the modern humans are known to be distinguished from other species by their extensive use of such tools as the ones that can be used for controlling and adapting to their surroundings. Mass production established different processes for creating the system and different parts with identical design and dimensions, but such processes can never be uniform.

Quality control can separate the act of testing different products for uncovering the defects from the decision in order to deny or allow any product release, which may be determined by different fiscal constraints. Quality control issues are known to be among the top reasons for not renewing the contracts and, thus, they have to be taken into consideration while working on some project.

The simplest form of quality control used to be a sketch of the desired item. In case such sketch does not match the item, it can be rejected, in the so-called “Go or No go” procedure. Nevertheless, some of the manufacturers found that it was difficult as well as costly to make different parts that have to be that similar their depiction. Thus, the so-called “tolerance limits” were introduced. Quality could be finally get precisely defined by using different devices such as ring gauges and plug gauges.

The previously mentioned decision did not address the problem of all of the defective items, that is why disposing and/or recycling of the waste is usually added to the cost of the final amount of all the produced items as a way of trying to reduce the defect rate. There were many different methods that have been proposed in order to prioritize many of the quality control issues as well as to determine whether it is needed to leave them unaddressed or use the so-called quality assurance techniques for improving and stabilizing the production as a whole.

There are also many different approaches to the quality assurance technique, such as the so-called “Failure testing”. It is a valuable process used for performing on a whole consumer product, also known as “stress testing”. It can be also described as the operation of a product until it fails, such as increasing vibration, humidity and temperature, often caused by the stresses.

The unanticipated weaknesses can appear in a product and so the data can be used for driving both the engineering and the manufacturing process improvements. Some simple changes can improve any product service sometimes, so it is important to think about such innovations from time to time. Statistical control is another approach that can be used in the quality assurance activity. It is known to be based on the different analyses of both subjective and objective data. Many different organizations use the so-called “statistical process control” as their tool for tracking the quality data. Any product can be charted in case there is a common cause variance or special cause variance to track.

The quality of products is known to be dependent on the participating constituents, some of which can be sustainable as well as effectively controlled, when others may be not. The process which can be managed with quality assurance is known to pertain the so-called “Total Quality Management”. In case some particular specification does not reflect the true quality requirements, the products’ quality cannot be guaranteed.

Quality assurance, same as quality control, can never be limited to manufacturing. Instead, it can be applied to any needed non-business and/or business activity, such as design, banking, consulting, insurance, retailing, investment, computer software development, transportation, translation and education. In construction and manufacturing activities, the mentioned business practices can be equated to the models for quality assurance that are defined by the International Standards which are known to be contained in the ISO 9000 series as well as the specified Specifications for quality systems.

Pic. 2. House of Quality Solution

Being involved in the quality control, it always makes sense to get the ConceptDraw DIAGRAM and ConceptDraw STORE applications, including the House of Quality solution from the last mentioned one.