The Value Stream Mapping Process

This graphical representation of a process is a powerful tool that helps in the diagnosis of process efficiency and allows companies to develop improved processes. Many lean practitioners use Value Stream Mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Other organizations use value stream mapping as a key portion of their lean efforts.

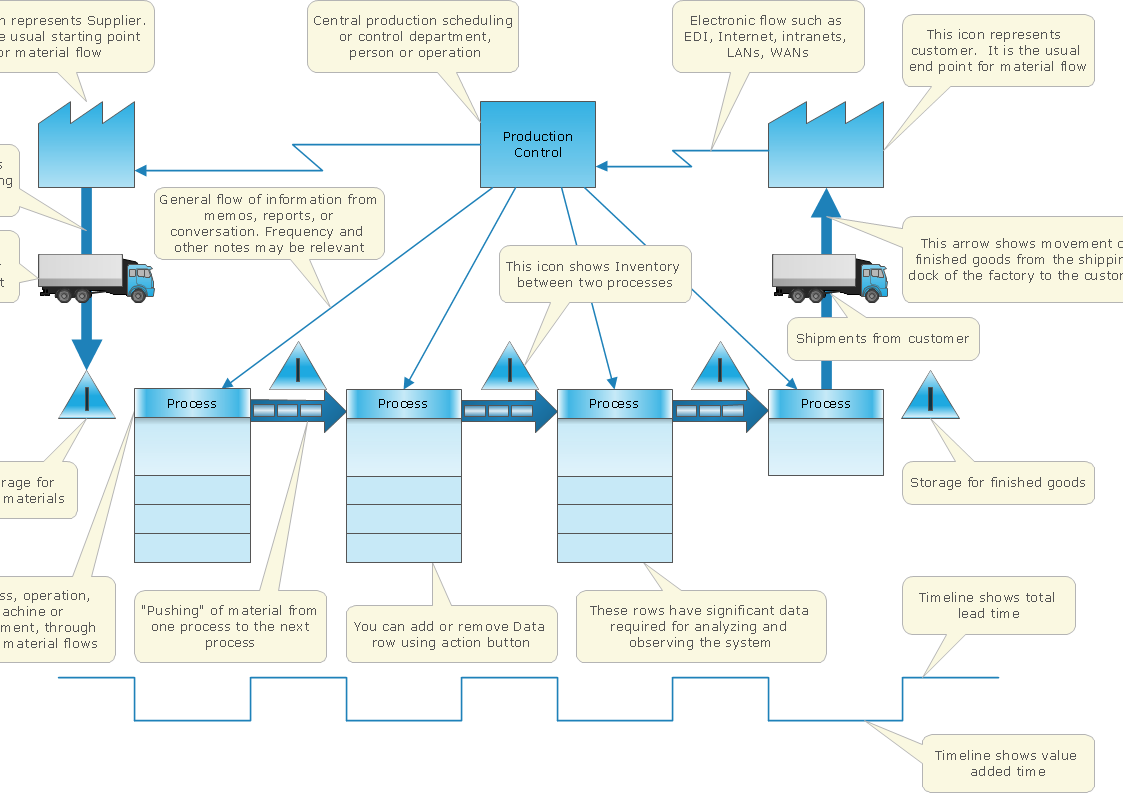

Pic.1 VSM diagram template.

Value Stream Maps are used in lean manufacturing methodology to analyze and identify the process improvement opportunities that are available.

See also Samples:

THREE RELATED HOW TO's:

Use ConceptDraw DIAGRAM software extended with Value Stream Mapping solution to create your own VSM diagrams.

Picture: Create a Value Stream Map

Related Solution:

ConceptDraw DIAGRAM diagramming and vector drawing software offers the unique Business Process Mapping Solution from the Business Processes Area of ConceptDraw Solution Park. Powerful drawing tools of this solution make it effective Business Process Mapping software and help easy design professional looking business process diagrams and flowcharts.

Picture: Process Mapping

Related Solution:

Value Stream & Process Flow Diagramming Software is a very popular Lean Manufacturing tool that allows to see and visualize in details the company's processes and current state, the flow of material and information, and thus gives the possibility to analyze the efficiency of company's processes and then develop improved processes. Value stream maps are also a good way to define the steps that do not add value to the end product, in other words waste in a company's processes.

Picture: Value Stream & Process Flow Diagramming Software

Related Solution:

ConceptDraw

MINDMAP 16