Value stream with ConceptDraw DIAGRAM

|

The Value stream is a totality of all actions on the projection, order composition and production: starting from creation a product project to launching this product, from order to delivery, from extraction of raw materials to ready product manufacturing. Value stream mapping is a process of visualization of these actions and creation of a detailed and graphical map which will give the possibility to cover the whole consecution of actions at once, to study and analyze it. Value stream map unites all information and material flows therefore such diagram let you see and comprehend the flow of materials, resources and documents in the process of a product manufacturing. As a rule Value stream maps are created manually on a paper, but with the help of ConceptDraw library objects you can create such map more accurately and quickly. Value stream method was developed and applied for the first time by Toyota company chief engineer in 80th of the last century as the new method of working out of wastes and for creation of more economical and competitive production. At the beginning this approach was head for the increase of productivity, which could help to discover shortages in relation to wastes and the quality of the system in general. Nevertheless this method is applied not only at work with the problem of wastes, but also with the problem of the low quality on the whole. The goal of the Value stream mapping is to reduce the quantity of wastes in the system of the final product manufacturing. By this method wastes are defined as resources motion, which does not increase the value of the final product but wastes resources. This method can help managers, planners, engineers, suppliers and clients to discover points of wastes rise in the system, to define reasons of wastes rise, to reduce their quantity and thus to increase the effectiveness of work of the whole system. In the process of Value stream map creation usually two schemes are created- of the current and future states. When the new state is achieved the scheme of the future state becomes the scheme of the current state and the next scheme of the future state is elaborated. The constituents of stream in Value Stream Map may be materials (at products manufacturing), projects (at projection), clients’ needs (at service providing) and so on. Wastes in the production system are divided into 7 categories: Wastes connected with quality

Categories connected with human resources

Categories connected with material resources

As soon as streams in Value Stream Map are divided into material and informational, objects of these streams are denoted by different images. Material objects

Informational objects

General notations

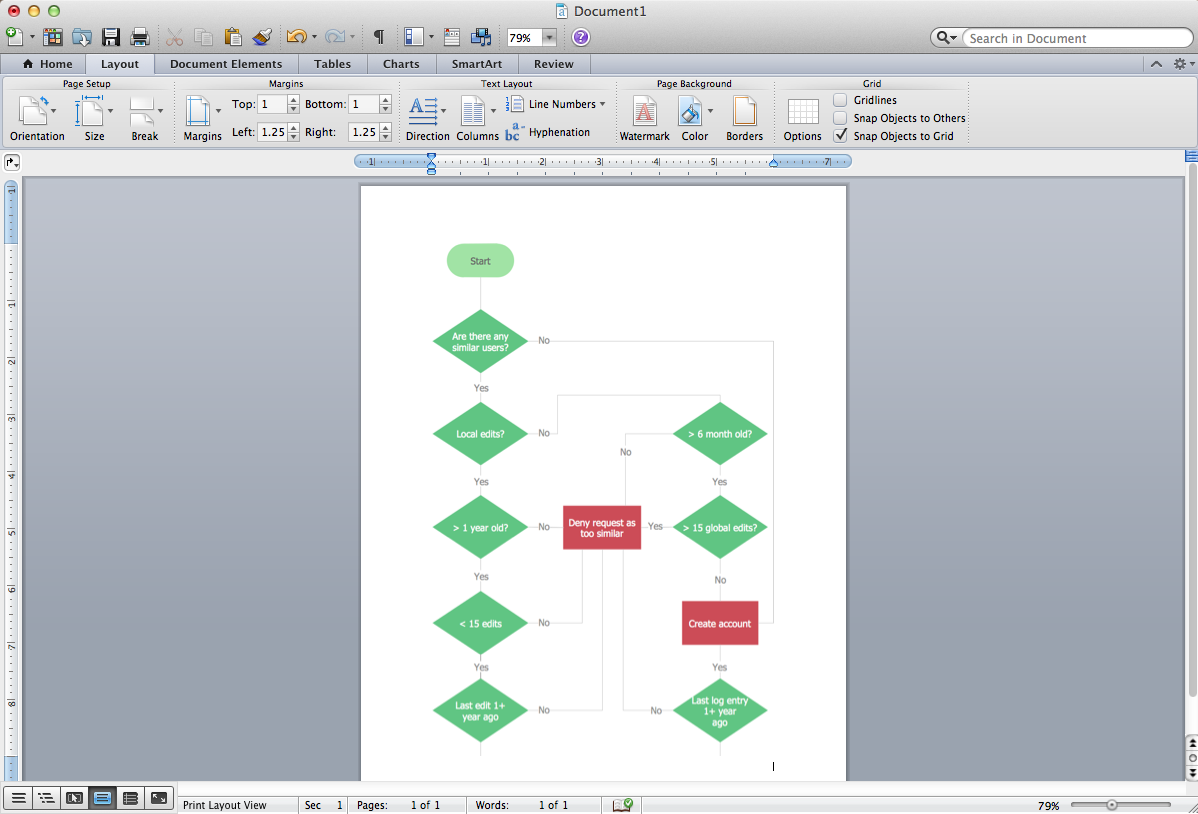

Also the so-called Tact time is shown on the scheme, which is defined as the relation of the effective working time for one shift to needs of the customer for a shift. For example if the tact time is 5 minutes so every 5 minutes the ready product will be manufactured on the production line or one client will be served, and so on. You can see below an example of Value Stream Map (Current State scheme). |