"The symbols and conventions used in welding documentation are specified in national and international standards such as ISO 2553 Welded, brazed and soldered joints -- Symbolic representation on drawings and ISO 4063 Welding and allied processes -- Nomenclature of processes and reference numbers. The US standard symbols are outlined by the American National Standards Institute and the American Welding Society and are noted as "ANSI/ AWS".

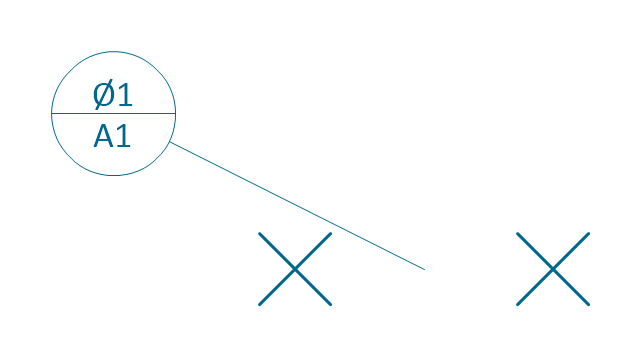

In engineering drawings, each weld is conventionally identified by an arrow which points to the joint to be welded. The arrow is annotated with letters, numbers and symbols which indicate the exact specification of the weld. In complex applications, such as those involving alloys other than mild steel, more information may be called for than can comfortably be indicated using the symbols alone. Annotations are used in these cases." [Symbols and conventions used in welding documentation. Wikipedia]

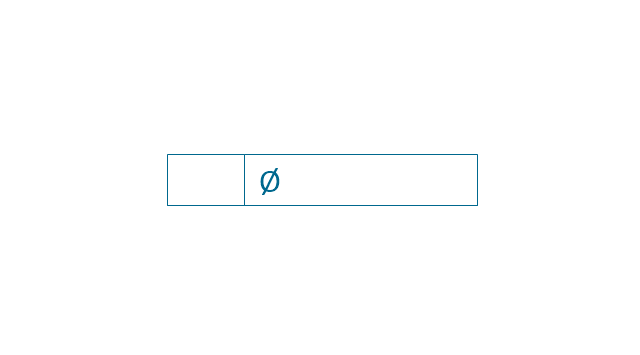

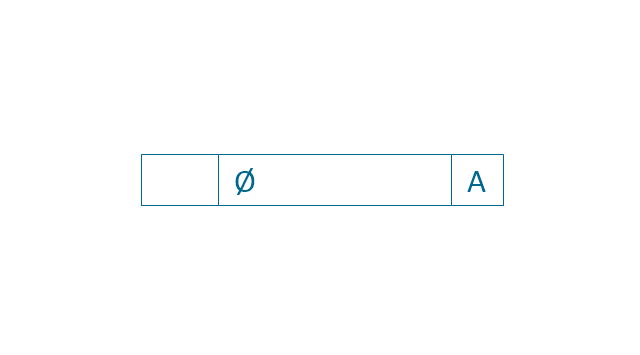

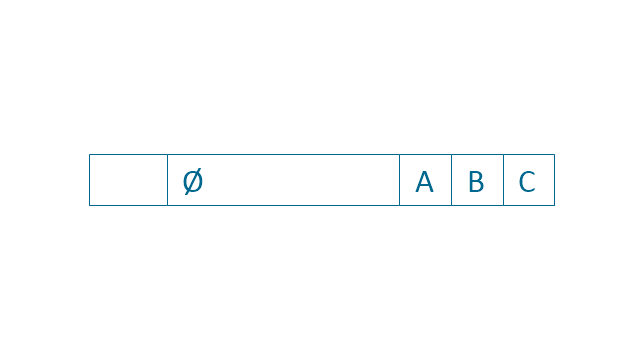

The example chart "Elements of welding symbol" is redesigned using the ConceptDraw PRO diagramming and vector drawing software from the Wikipedia file: Elements of a welding symbol.PNG.

[en.wikipedia.org/ wiki/ File:Elements_ of_ a_ welding_ symbol.PNG]

The diagram example "Elements location of a welding symbol" is contained in the Mechanical Engineering solution from the Engineering area of ConceptDraw Solution Park.

In engineering drawings, each weld is conventionally identified by an arrow which points to the joint to be welded. The arrow is annotated with letters, numbers and symbols which indicate the exact specification of the weld. In complex applications, such as those involving alloys other than mild steel, more information may be called for than can comfortably be indicated using the symbols alone. Annotations are used in these cases." [Symbols and conventions used in welding documentation. Wikipedia]

The example chart "Elements of welding symbol" is redesigned using the ConceptDraw PRO diagramming and vector drawing software from the Wikipedia file: Elements of a welding symbol.PNG.

[en.wikipedia.org/ wiki/ File:Elements_ of_ a_ welding_ symbol.PNG]

The diagram example "Elements location of a welding symbol" is contained in the Mechanical Engineering solution from the Engineering area of ConceptDraw Solution Park.

Mechanical Engineering

Mechanical Engineering

This solution extends ConceptDraw PRO v.9 mechanical drawing software (or later) with samples of mechanical drawing symbols, templates and libraries of design elements, for help when drafting mechanical engineering drawings, or parts, assembly, pneumatic,

HelpDesk

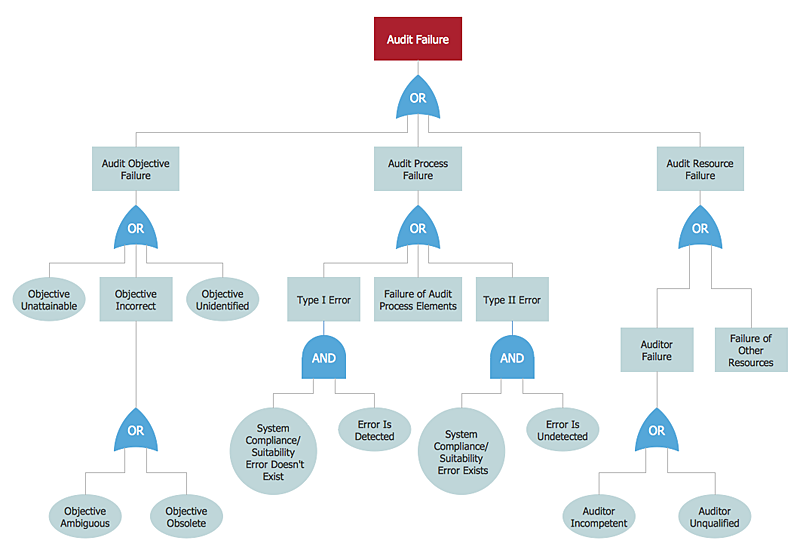

How to Create a Fault Tree Analysis Diagram (FTD) in ConceptDraw PRO

Fault Tree Diagram are logic diagram that shows the state of an entire system in a relationship of the conditions of its elements. Fault Tree Diagram are used to analyze the probability of functional system failures and safety accidents. ConceptDraw PRO allows you to create professional Fault Tree Diagrams using the basic FTD symbols. An FTD visualize a model of the processes within a system that can lead to the unlikely event. A fault tree diagrams are created using standard logic symbols . The basic elements in a fault tree diagram are gates and events.HelpDesk

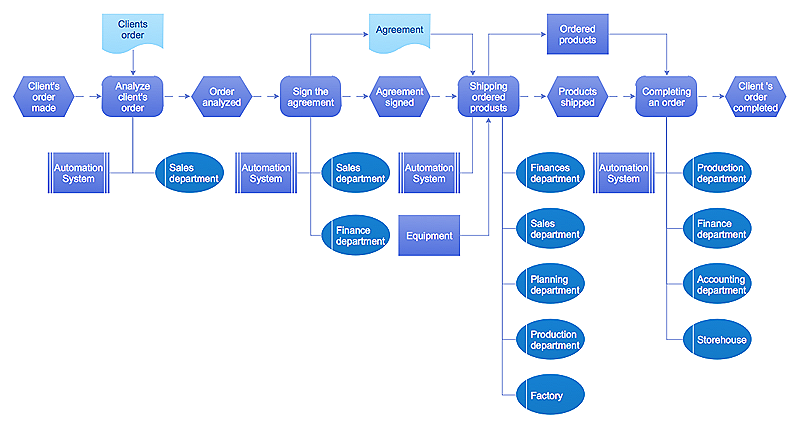

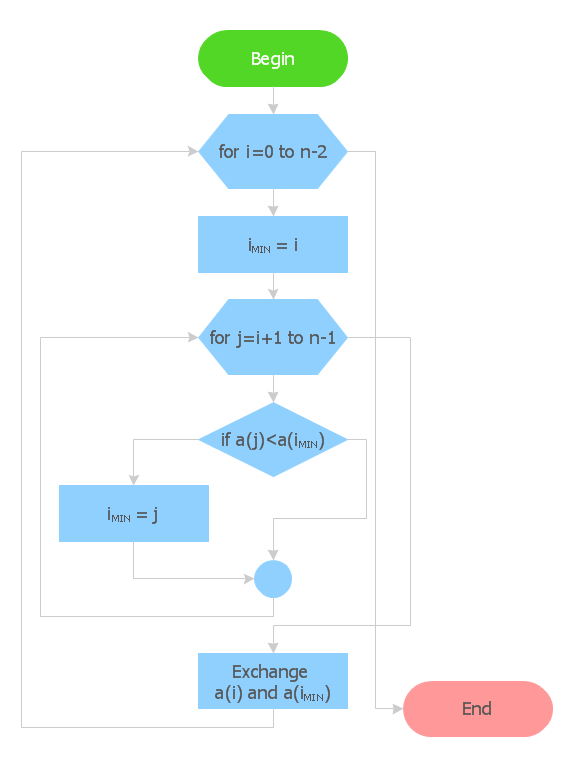

How to Create Flowchart Using Standard Flowchart Symbols

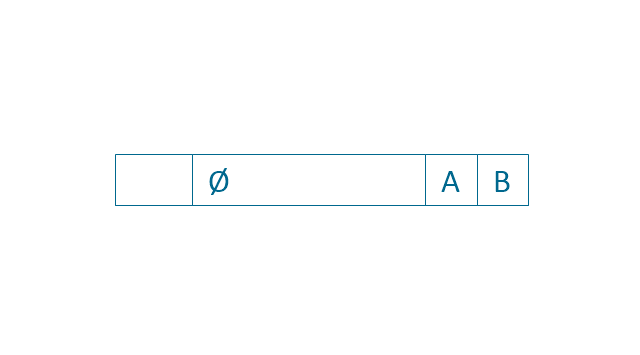

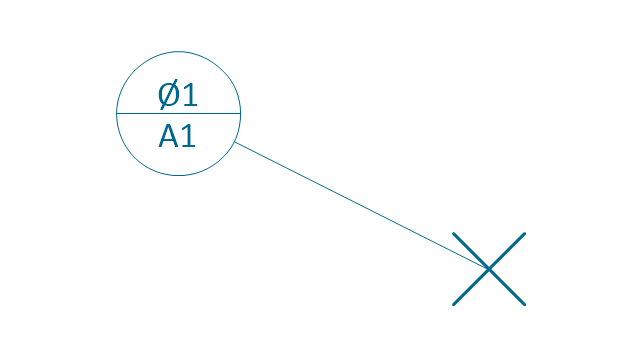

Flowcharts are used to display an algorithm for consistent execution of certain steps. Flowchart is probably the easiest way to make a graphical representation of any process. Flowcharts use the set of standard geometric symbols and arrows to define relationships. ConceptDraw PRO allows you to create professional flowchart quickly and easily. The ability to create flowcharts is contained in the Flowcharts solution. The solution provides a set of special tools for creating flowcharts.The vector stencils library "Dimensioning and tolerancing" contains 45 symbols of geometric dimensions and mechanical tolerances, geometric symbols, callouts, and text boxes and inserts.

Use these geometric dimensioning and tolerancing (GD&T) shapes to create annotated mechanical drawings in the ConceptDraw PRO diagramming and vector drawing software extended with the Mechanical Engineering solution from the Engineering area of ConceptDraw Solution Park.

www.conceptdraw.com/ solution-park/ engineering-mechanical

Use these geometric dimensioning and tolerancing (GD&T) shapes to create annotated mechanical drawings in the ConceptDraw PRO diagramming and vector drawing software extended with the Mechanical Engineering solution from the Engineering area of ConceptDraw Solution Park.

www.conceptdraw.com/ solution-park/ engineering-mechanical

ConceptDraw Solution Park

ConceptDraw Solution Park

ConceptDraw Solution Park collects graphic extensions, examples and learning materials

HelpDesk

Event-driven Process Chain (EPC) Diagram Software

An EPC diagram is a type of flowchart used in business process analysis. It shows different business processes through various work flows. The workflows are shown as processes and events that are related to different executes and tasks that allow business workflow to be completed. An EPC diagram shows different business processes through various workflows. The workflows are seen as functions and events that are connected by different teams or people, as well as tasks that allow business processes to be executed. The best thing about this type of enterprise modelling is that creating an EPC diagram is quick and simple as long as you have the proper tool. One of the main usages of the EPC diagrams is in the modelling, analyzing and re-engineering of business processes. With the use of the flowchart, businesses are able to see inefficiencies in the processes and modify to make them more productive. Event-driven process chain diagrams are also used to configure an enterprise resource pla- Basic Symbol In Mechanical Engineering

- All Basic Mechanical Engineering Symbol

- Types Of Mechanical Drawing Symbol Emphasis Machine Symbols

- Elements location of a welding symbol | Basic Nomenclature In ...

- What Is The Basic Symbol In Technical Drawing

- Mechanical Drawing Symbols | Basic Flowchart Symbols and ...

- Mechanical Drawing Symbol S

- Symbol And Explanation Of Mechanical Drawing

- Mechanical Drawing Symbols | Process Flow Diagram Symbols ...

- Mechanical Drawing Symbols | Mechanical Engineering | Basic ...

- Quality Drawing Symbol

- Process Flowchart | Elements location of a welding symbol | Basic ...

- Technical Drawing Software | Mechanical Engineering | Elements ...

- Mechanical Drawing Symbols | Mechanical Engineering | Elements ...

- Common joint types | Welded joints types | Butt weld geometry ...

- Mechanical Drawing Symbols | Elements location of a welding ...

- Elements location of a welding symbol | Building Drawing

- Mechanical Engineering | ConceptDraw Solution Park | Total Quality ...

- Mechanical Drawing Symbols | Elements location of a welding ...

- Mechanical Engineering | Technical drawing - Machine parts ...

-dimensioning-and-tolerancing---vector-stencils-library.png--diagram-flowchart-example.png)

-dimensioning-and-tolerancing---vector-stencils-library.png--diagram-flowchart-example.png)

-2-dimensioning-and-tolerancing---vector-stencils-library.png--diagram-flowchart-example.png)

-dimensioning-and-tolerancing---vector-stencils-library.png--diagram-flowchart-example.png)

-dimensioning-and-tolerancing---vector-stencils-library.png--diagram-flowchart-example.png)