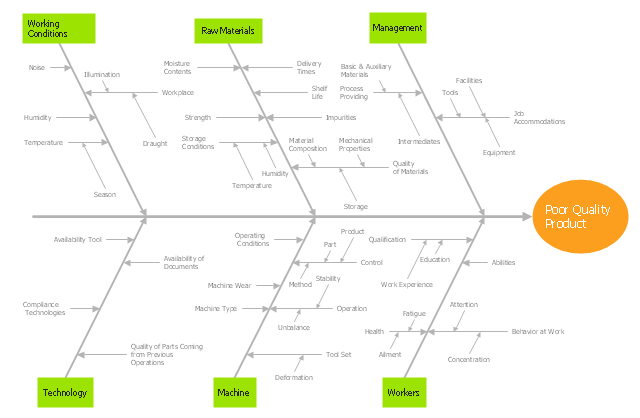

"Ishikawa diagrams (also called fishbone diagrams, herringbone diagrams, cause-and-effect diagrams, or Fishikawa) are causal diagrams created by Kaoru Ishikawa (1968) that show the causes of a specific event. Common uses of the Ishikawa diagram are product design and quality defect prevention, to identify potential factors causing an overall effect. Each cause or reason for imperfection is a source of variation. Causes are usually grouped into major categories to identify these sources of variation. The categories typically include:

- People: Anyone involved with the process

- Methods: How the process is performed and the specific requirements for doing it, such as policies, procedures, rules, regulations and laws

- Machines: Any equipment, computers, tools, etc. required to accomplish the job

- Materials: Raw materials, parts, pens, paper, etc. used to produce the final product

- Measurements: Data generated from the process that are used to evaluate its quality

- Environment: The conditions, such as location, time, temperature, and culture in which the process operates" [Ishikawa diagram. Wikipedia]

The fishbone diagram example "Causes of low-quality output" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park.

- People: Anyone involved with the process

- Methods: How the process is performed and the specific requirements for doing it, such as policies, procedures, rules, regulations and laws

- Machines: Any equipment, computers, tools, etc. required to accomplish the job

- Materials: Raw materials, parts, pens, paper, etc. used to produce the final product

- Measurements: Data generated from the process that are used to evaluate its quality

- Environment: The conditions, such as location, time, temperature, and culture in which the process operates" [Ishikawa diagram. Wikipedia]

The fishbone diagram example "Causes of low-quality output" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park.

- Create Fishbone Diagrams | Cause and Effect Analysis - Fishbone ...

- Fishbone diagram - Causes of low-quality output | TQM Diagram ...

- What is a Quality Management | Process Flowchart | Quality Criteria ...

- Ishikawa Diagram For Problem Defective Product

- Cause and Effect Analysis - Fishbone Diagrams for Problem Solving ...

- Cause And Effect Diagram For Poor Quality Product

- Fishbone diagram - Causes of low-quality output | Design elements ...

- Fishbone diagram - Causes of low-quality output | Total Quality ...

- Fishbone Diagrams | Process Flowchart | Fishbone Diagram ...

- Cause and Effect Diagrams | Cause and Effect Analysis - Fishbone ...

- Total Quality Management Value | Cause and effect diagram ...

- Cause and Effect Analysis - Fishbone Diagrams for Problem Solving ...

- Fishbone diagram - Causes of low-quality output | Fishbone ...

- TQM Diagram Tool | Fishbone diagram - Causes of low-quality ...

- How to Construct a Fishbone Diagram | Cause and Effect Diagram ...

- Fishbone Diagram Poor Quality Of Product

- Design elements - Cause -and- effect diagram | Fishbone diagram ...

- Cause and Effect Analysis - Fishbone Diagrams for Problem Solving ...

- Cause And Effect Low Quality Product