"Value stream mapping is a lean management principle used to analyze and design the flow of materials and information required to bring a product or service to a consumer. Pioneered by Henry Ford in the 1920s, perfected by Toyota. At Toyota, it is known as "material and information flow mapping". It can be applied to nearly any value chain. ...

Value stream mapping has supporting methods that are often used in Lean environments to analyze and design flows at the system level (across multiple processes).

Although value stream mapping is often associated with manufacturing, it is also used in logistics, supply chain, service related industries, healthcare, software development, product development, and administrative and office processes." [Value stream mapping. Wikipedia]

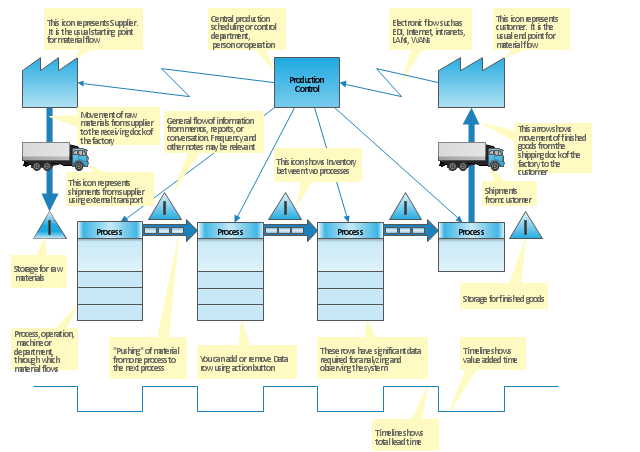

This value stream map template explains the meanings of the VSM design elements.

This Value stream map template for the ConceptDraw PRO diagramming and vector drawing software is included in the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

Value stream mapping has supporting methods that are often used in Lean environments to analyze and design flows at the system level (across multiple processes).

Although value stream mapping is often associated with manufacturing, it is also used in logistics, supply chain, service related industries, healthcare, software development, product development, and administrative and office processes." [Value stream mapping. Wikipedia]

This value stream map template explains the meanings of the VSM design elements.

This Value stream map template for the ConceptDraw PRO diagramming and vector drawing software is included in the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

"Value stream mapping is a lean management principle used to analyze and design the flow of materials and information required to bring a product or service to a consumer. Pioneered by Henry Ford in the 1920s, perfected by Toyota. At Toyota, it is known as "material and information flow mapping". It can be applied to nearly any value chain. ...

Value stream mapping has supporting methods that are often used in Lean environments to analyze and design flows at the system level (across multiple processes).

Although value stream mapping is often associated with manufacturing, it is also used in logistics, supply chain, service related industries, healthcare, software development, product development, and administrative and office processes." [Value stream mapping. Wikipedia]

This value stream map template explains the meanings of the VSM design elements.

This Value stream map template for the ConceptDraw PRO diagramming and vector drawing software is included in the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

Value stream mapping has supporting methods that are often used in Lean environments to analyze and design flows at the system level (across multiple processes).

Although value stream mapping is often associated with manufacturing, it is also used in logistics, supply chain, service related industries, healthcare, software development, product development, and administrative and office processes." [Value stream mapping. Wikipedia]

This value stream map template explains the meanings of the VSM design elements.

This Value stream map template for the ConceptDraw PRO diagramming and vector drawing software is included in the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

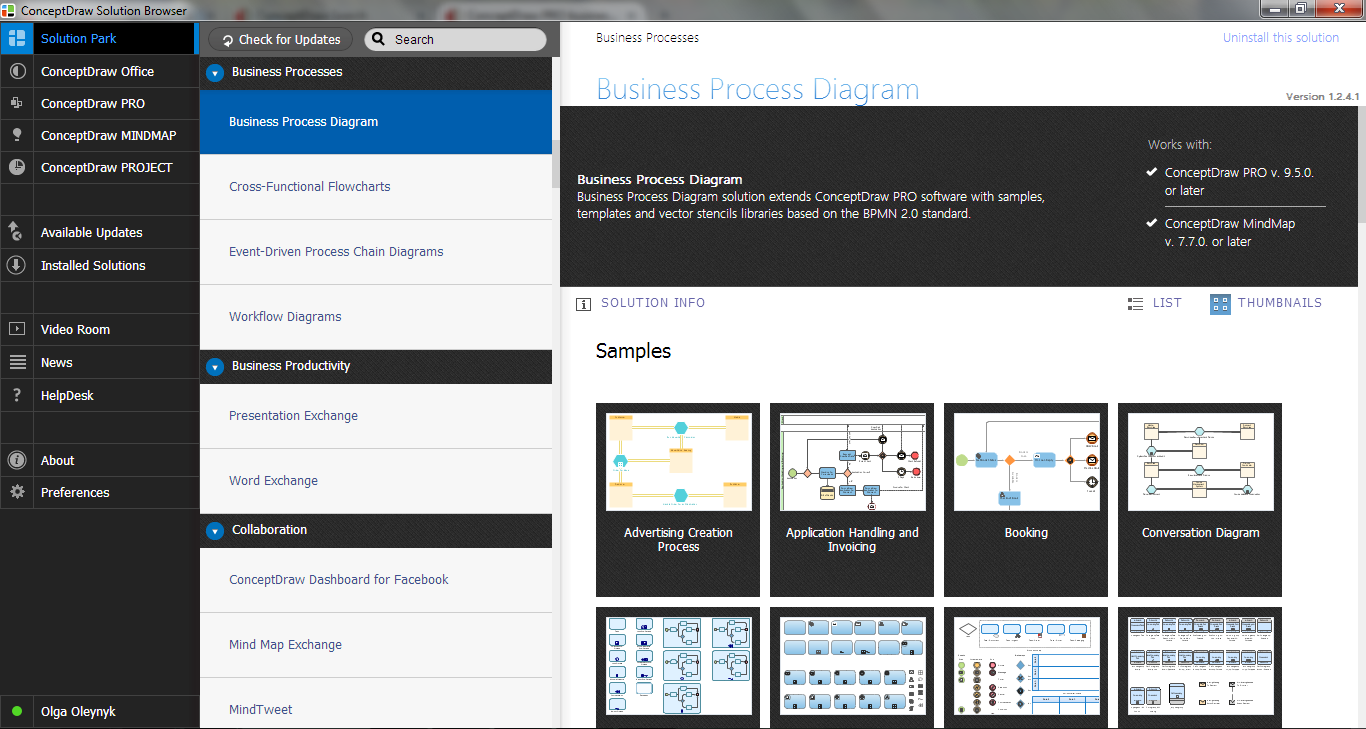

ConceptDraw PRO

ConceptDraw PRO is a powerful business and technical diagramming software tool that enables you to design professional-looking graphics, diagrams, flowcharts, floor plans and much more in just minutes. Maintain business processes performance with clear visual documentation. Effectively present and communicate information in a clear and concise manner with ConceptDraw PRO.

Event-driven Process Chain Diagrams

Event-driven Process Chain Diagrams

Event-driven Process Chain (EPC) Diagram is a type of flowchart widely used for modeling in business engineering and reengineering, business process improvement, and analysis. EPC method was developed within the Architecture of Integrated Information Systems (ARIS) framework.

- Process Flowchart | Data Flow Diagram Model | Manufacturing 8 Ms ...

- Value Stream Mapping Production Control

- Value stream mapping

- Process Mapping Of Shipment

- Value stream mapping - Vector stencils library | Design elements ...

- Cross-Functional Process Map Template

- Value Stream Mapping Information Control

- Value Stream Mapping Shipping

- Value stream mapping - Vector stencils library | Value stream map ...

- Value stream mapping - Vector stencils library | Value stream ...

- Value Stream Map Data Box

- Value Stream Mapping Stencil

- Process Flowchart | How to Create Flowcharts for an Accounting ...

- Cross-Functional Process Map Template | Process Flowchart | Basic ...

- Cross-Functional Flowchart (Swim Lanes) | Swim Lane Diagrams ...

- Manufacturing 8 Ms fishbone diagram - Template | How Do ...

- Value stream map - Template

- Inventory Management Flowchart Small

- Functional Block Diagram | Basic Flowchart Symbols and Meaning ...

- Logistics - Choreography BPMN 2.0 diagram | Process Flowchart ...