GHS Hazard Pictograms

GHS Hazard Pictograms

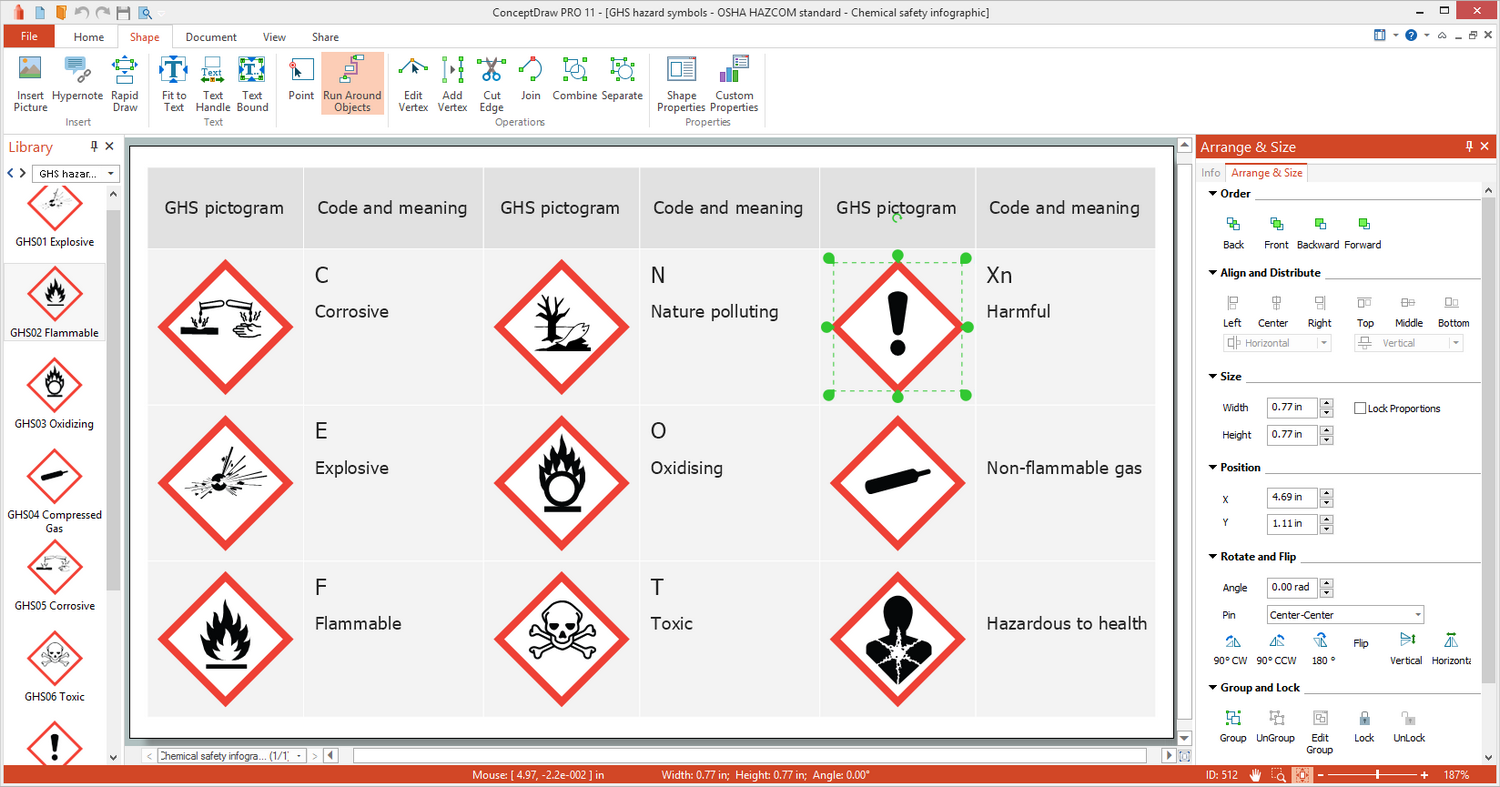

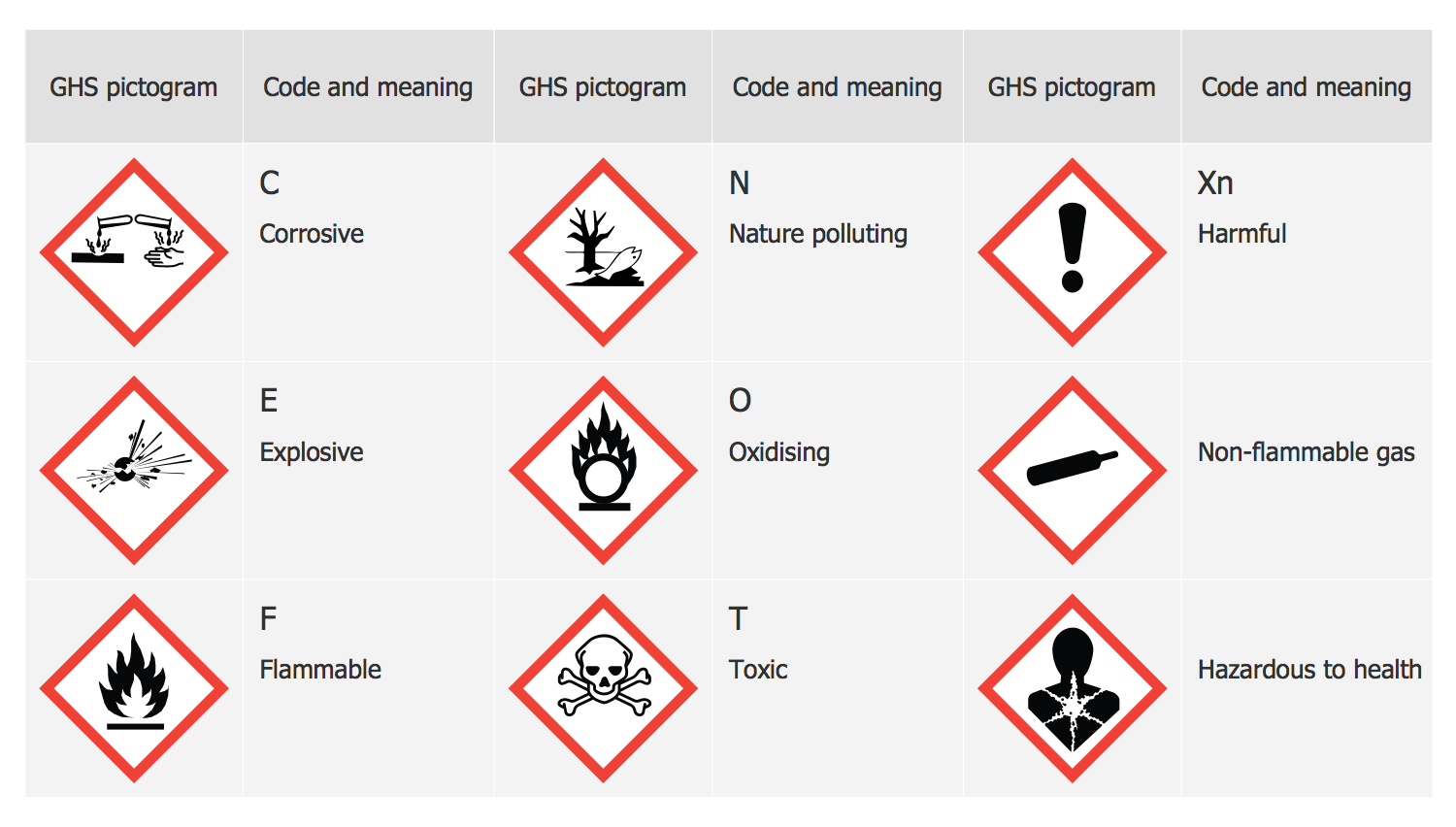

GHS Hazard Pictograms solution contains the set of predesigned standard GHS pictograms, Hazardous symbols, and Hazard communication pictograms, approved and agreed by UN in Globally Harmonized System of Classification and Labelling of Chemicals (GHS). They can be used for quick and simple designing accurate and professional-looking infographics, diagrams, warning announcements, signboards, posters, precautionary declarations, regulatory documents, and for representing the main items of OSHA HAZCOM Standard.

Transport Hazard Pictograms

Transport Hazard Pictograms

Transport Hazard Pictograms solution includes large variety of specially developed samples with transport hazard symbols and pictograms, and the whole set of predesigned vector transport GHS pictograms download and used with ease from the Transport Hazard Pictograms library. Apply them for quick designing professional-looking infographics and diagrams, use them to create warning signboards and announcements on all stages of the transportation process, to place them on the transport vehicles and warehouses of transportation companies, at the transport documentation and on the websites of transport and logistics companies.

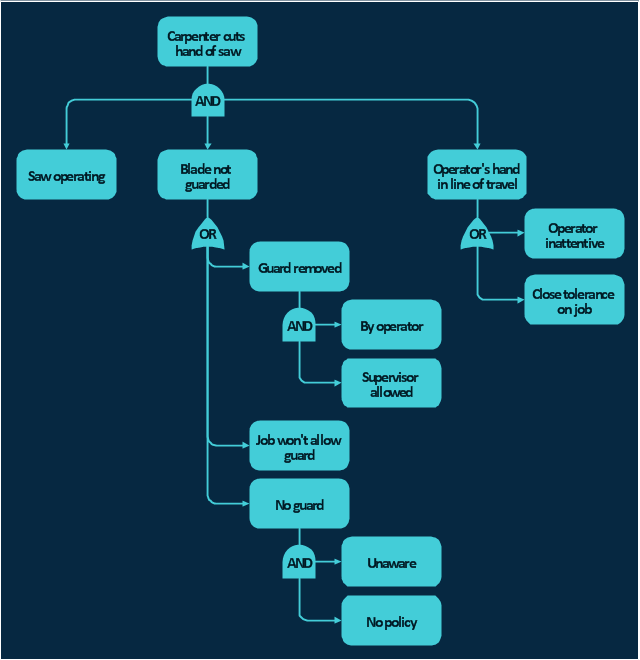

The FTA diagram example "Hazard analysis" was redesigned from the illustration of the article "Hazard Analysis Methodologies" from the Occupational Safety & Health Administration (OSHA) website.

"A fault tree analysis is a quantitative assessment of all of the undesirable outcomes, such as a toxic gas release or explosion, which could result from a specific initiating event. It begins with a graphic representation (using logic symbols) of all possible sequences of events that could result in an incident. The resulting diagram looks like a tree with many branches — each branch listing the sequential events (failures) for different independent paths to the top event. Probabilities (using failure rate data) are assigned to each event and then used to calculate the probability of occurrence of the undesired event. ...

This technique is particularly useful in evaluating the effect of alternative actions on reducing the probability of occurrence of the undesired event."

[osha.gov/ SLTC/ etools/ safetyhealth/ mod4_ tools_ methodologies.html]

The FTA diagram example "Hazard analysis" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Fault Tree Analysis Diagrams solution from the Engineering area of ConceptDraw Solution Park.

"A fault tree analysis is a quantitative assessment of all of the undesirable outcomes, such as a toxic gas release or explosion, which could result from a specific initiating event. It begins with a graphic representation (using logic symbols) of all possible sequences of events that could result in an incident. The resulting diagram looks like a tree with many branches — each branch listing the sequential events (failures) for different independent paths to the top event. Probabilities (using failure rate data) are assigned to each event and then used to calculate the probability of occurrence of the undesired event. ...

This technique is particularly useful in evaluating the effect of alternative actions on reducing the probability of occurrence of the undesired event."

[osha.gov/ SLTC/ etools/ safetyhealth/ mod4_ tools_ methodologies.html]

The FTA diagram example "Hazard analysis" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Fault Tree Analysis Diagrams solution from the Engineering area of ConceptDraw Solution Park.

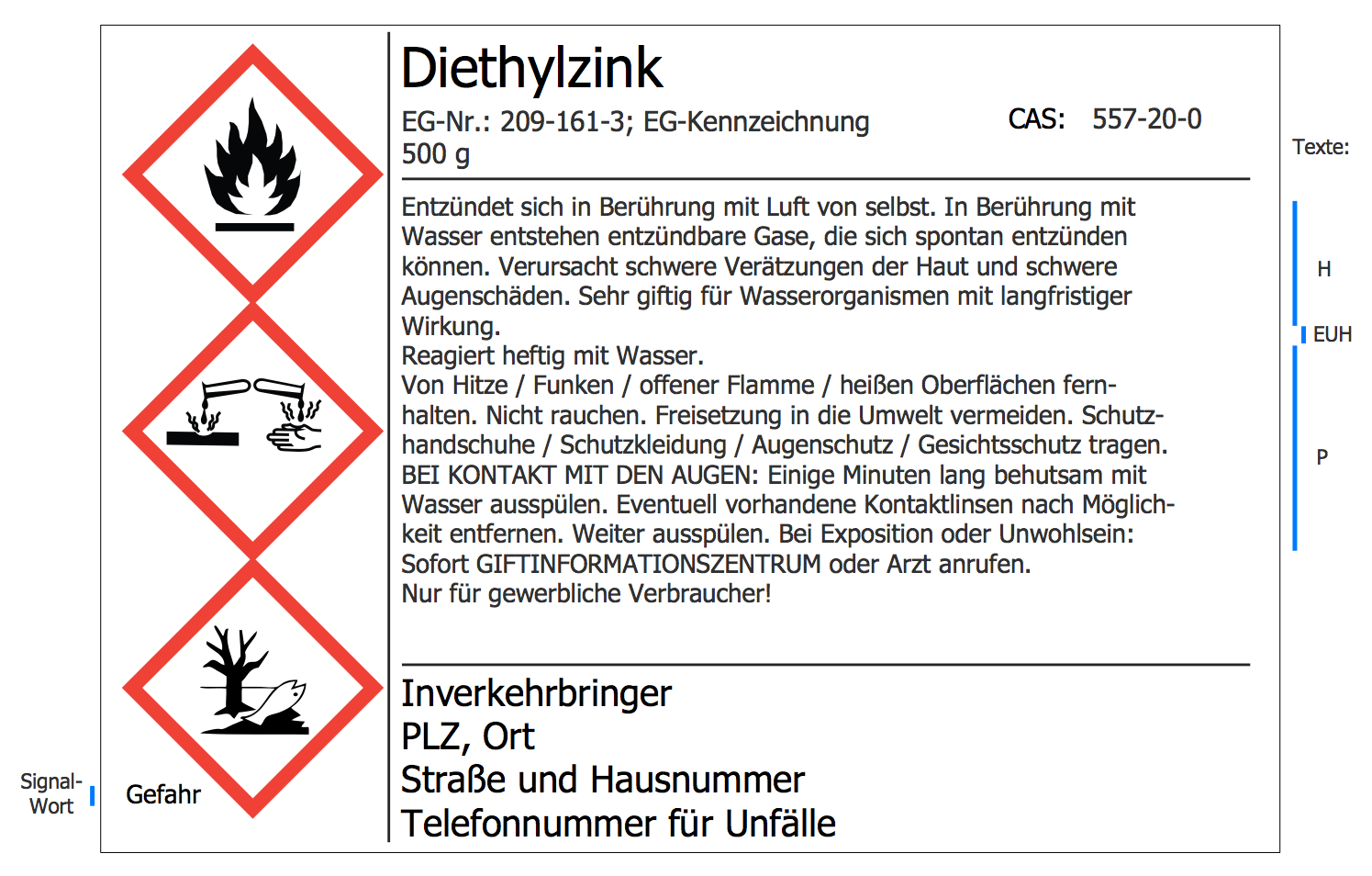

Hazard Pictograms

ConceptDraw DIAGRAM diagramming and vector drawing software enhanced with GHS Hazard Pictograms Solution from the Industrial Engineering Area of ConceptDraw Solution Park offers the GHS Hazard Pictograms library with whole set of predesigned standard Hazard pictograms for easy designing professional-looking Chemical safety infographics and Hazard diagrams.Hazard Chemical Sign

For each group of hazardous materials is designed its own hazard chemical sign, commonly used and approved at Globally Harmonized System of Classification and Labelling of Chemicals (GHS). The GHS Hazard Pictograms library offered by GHS Hazard Pictograms solution for ConceptDraw DIAGRAM diagramming software provides the predesigned vector objects for all standard GHS hazard pictograms: Explosive, Flammable, Oxidizing, Compressed Gas, Corrosive, Toxic, Harmful, Health Hazard, Environmental Hazard.GHS Labels Meanings

The innovative GHS Hazard Pictograms Solution from the Industrial Engineering Area of ConceptDraw Solution Park offers for ConceptDraw DIAGRAM users the whole collection of predesigned GHS label pictograms with GHS labels meanings. Their use helps to overcome easily all the difficulties that can arise while creating professional-looking chemical safety diagrams and infographics.OSHA HAZCOM pictograms

ConceptDraw DIAGRAM diagramming and vector drawing software supplied with GHS Hazard Pictograms Solution from the Industrial Engineering Area of ConceptDraw Solution Park offers the OSHA HAZCOM pictograms, GHS hazard pictograms for easy representing the OSHA's program positions and requirements in a simple and visual way.

Fault Tree Analysis Diagrams

Fault Tree Analysis Diagrams

This solution extends ConceptDraw DIAGRAM.5 or later with templates, fault tree analysis example, samples and a library of vector design elements for drawing FTA diagrams (or negative analytical trees), cause and effect diagrams and fault tree diagrams.

GHS Label Pictograms

Hazard pictograms are those which form a part of the international GHS which is a “Globally Harmonized System of Classification and Labelling of Chemicals. Two sets of pictograms are included within the GHS: one for the labelling of containers and for workplace hazard warnings, and a second for use during the transport of dangerous goods. Either one or the other is chosen, depending on the target audience, but the two are not used together.The vector stencils library "Fault tree analysis diagrams" contains 12 symbols for drawing Fault Tree Analysis (FTA) diagrams.

"Fault tree analysis (FTA) is a top down, deductive failure analysis in which an undesired state of a system is analyzed using Boolean logic to combine a series of lower-level events. This analysis method is mainly used in the fields of safety engineering and reliability engineering to understand how systems can fail, to identify the best ways to reduce risk or to determine (or get a feeling for) event rates of a safety accident or a particular system level (functional) failure. FTA is used in the aerospace, nuclear power, chemical and process, pharmaceutical, petrochemical and other high-hazard industries; but is also used in fields as diverse as risk factor identification relating to social service system failure.

In aerospace, the more general term "system Failure Condition" is used for the "undesired state" / Top event of the fault tree. These conditions are classified by the severity of their effects. The most severe conditions require the most extensive fault tree analysis. These "system Failure Conditions" and their classification are often previously determined in the functional Hazard analysis." [Fault tree analysis. Wikipedia]

The shapes example "Fault tree analysis diagrams" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Fault Tree Analysis Diagrams solution from the Engineering area of ConceptDraw Solution Park.

"Fault tree analysis (FTA) is a top down, deductive failure analysis in which an undesired state of a system is analyzed using Boolean logic to combine a series of lower-level events. This analysis method is mainly used in the fields of safety engineering and reliability engineering to understand how systems can fail, to identify the best ways to reduce risk or to determine (or get a feeling for) event rates of a safety accident or a particular system level (functional) failure. FTA is used in the aerospace, nuclear power, chemical and process, pharmaceutical, petrochemical and other high-hazard industries; but is also used in fields as diverse as risk factor identification relating to social service system failure.

In aerospace, the more general term "system Failure Condition" is used for the "undesired state" / Top event of the fault tree. These conditions are classified by the severity of their effects. The most severe conditions require the most extensive fault tree analysis. These "system Failure Conditions" and their classification are often previously determined in the functional Hazard analysis." [Fault tree analysis. Wikipedia]

The shapes example "Fault tree analysis diagrams" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Fault Tree Analysis Diagrams solution from the Engineering area of ConceptDraw Solution Park.

- FTA diagram - Hazard analysis | Accident analytic tree - FTA ...

- FTA diagram - Hazard analysis | Fault Tree Analysis Diagrams ...

- Transport Hazard Pictograms | FTA diagram - Hazard analysis ...

- Logistics Flow Charts | Flow chart Example . Warehouse Flowchart ...

- Import process - Flowchart | Block diagram - Selling technology ...

- GHS Hazard Pictograms | Network Security Devices | Flow chart ...

- Transport Hazard Pictograms | Pyramid Diagram | Competitor ...

- Intelligent transportation system | Fault Tree Analysis Diagrams ...

- Import process - Flowchart | Transport Hazard Pictograms | SWOT ...

- GHS Hazard Pictograms | OSHA HAZCOM pictograms | Accounting ...