HelpDesk

How to Create a VSM Diagram Using ConceptDraw Value Stream Mapping Solution

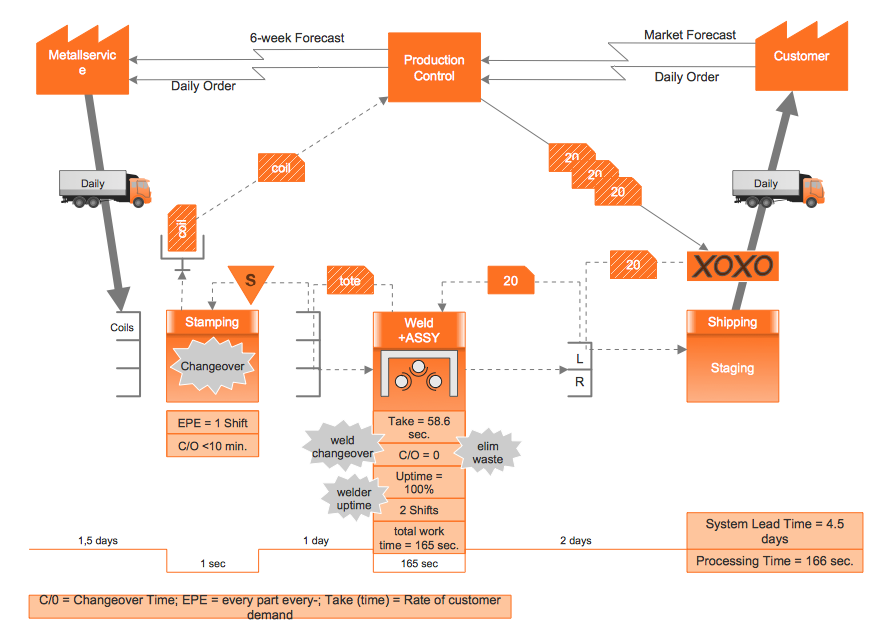

Value Stream Mapping is a Lean Manufacturing tool that uses a flow diagram to document in great detail every step of a manufacturing process. This graphical representation of a process is a powerful tool that helps in the diagnosis of process efficiency and allows companies to develop improved processes. Many lean practitioners use Value Stream Mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Many organizations use value stream mapping as a key portion of their lean efforts. Value Stream Maps are used to analyze and design the flow of materials and information required to bring a product or service to a consumer. You can create a Value Stream Mapping flowchart using ConceptDraw PRO tools.HelpDesk

How to Create a Plant Layout Design

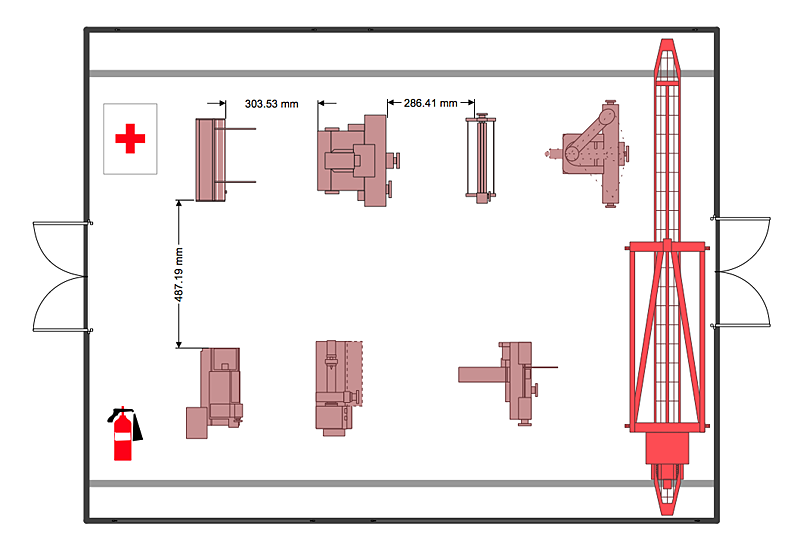

A plant construction process begins from a plant layout stage - an engineering stage used to design, analyze and finally choose the suitable configurations for a manufacturing plant. Plant Layout issues are core to any enterprise and are challenged in all types of manufacturing process. The sufficiency of layout influences the efficiency of subsequent operations. It is an important background for efficient manufacturing and also has a great deal with many questions. Once the place of the plant has been determined, the next important task before the management of the plant is to plan appropriate layout for the enterprise. Plant layout is used to create the most effective physical arrangement of machinery and equipment, with the plant building in such a manner so as to make quickest and cheapest way from a raw material to the shipment of the completed product Making a plan that shows the location of industrial equipment involves many different elements that can be managed using Con- Production Planning Process Flowchart

- Process Flowchart | Data Flow Diagram Model | Flow chart Example ...

- Process Flow Chart Of Production Planning

- Process Flowchart | Material Requisition Flowchart . Flowchart ...

- Material Requisition Flowchart . Flowchart Examples | Process ...

- Process Flowchart | Basic Flowchart Symbols and Meaning ...

- Manufacturing Pictures Diagram

- Manufacturing 8 Ms fishbone diagram - Template | Business ...

- Design Of A Flow Chart For A Manufacturing Process

- Value-Stream Mapping for Manufacturing | Lean Manufacturing ...

- Material Requisition Flowchart . Flowchart Examples | Workflow ...

- Process Flowchart | Basic Flowchart Symbols and Meaning | Flow ...

- Process decision program chart (PDPC) - Personal activity | Process ...

- Production Process Flow Chart

- Manufacturing Process Flow Chart

- Process Flowchart | Design elements - Industrial equipment | Interior ...

- Value-Stream Mapping for Manufacturing | PROBLEM ANALYSIS ...

- Process Flowchart | Sales Process Flowchart . Flowchart Examples ...

- Flow chart Example. Warehouse Flowchart | Warehouse layout floor ...

- Material Requisition Flowchart . Flowchart Examples | Flow chart ...