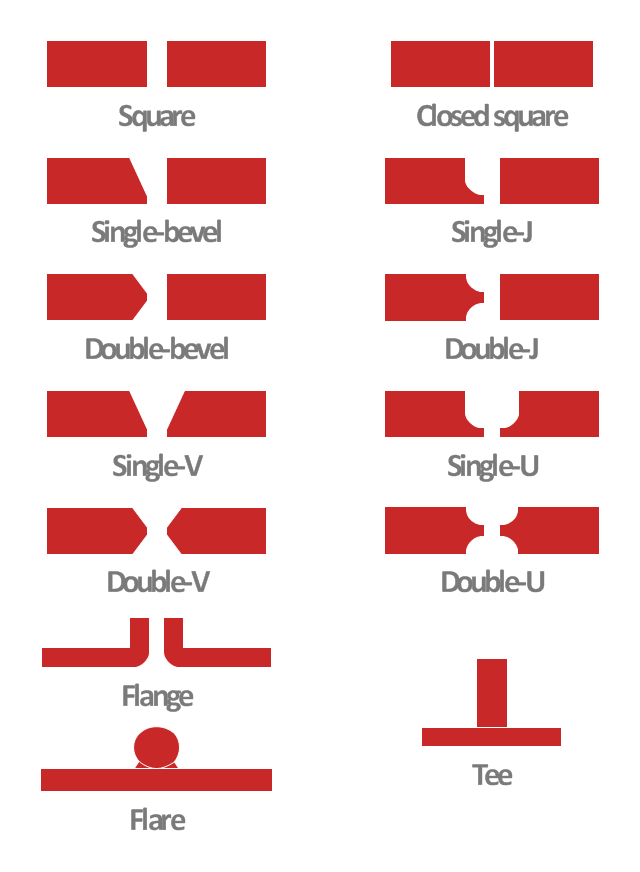

This engineering drawing shows different types of geometry of butt welds.

"Welds can be geometrically prepared in many different ways. The five basic types of weld joints are the butt joint, lap joint, corner joint, edge joint, and T-joint (a variant of this last is the cruciform joint). Other variations exist as well - for example, double-V preparation joints are characterized by the two pieces of material each tapering to a single center point at one-half their height. Single-U and double-U preparation joints are also fairly common - instead of having straight edges like the single-V and double-V preparation joints, they are curved, forming the shape of a U. Lap joints are also commonly more than two pieces thick - depending on the process used and the thickness of the material, many pieces can be welded together in a lap joint geometry." [Welding. Wikipedia]

This engineering drawing example was redesigned using the ConceptDraw PRO diagramming and vector drawing software from the Wikimedia Commons file: Butt Weld Geometry.GIF.

[commons.wikimedia.org/ wiki/ File:Butt_ Weld_ Geometry.GIF]

The engineering drawing example "Butt weld geometry" is included in the Mechanical Engineering solution from the Engineering area of ConceptDraw Solution Park.

"Welds can be geometrically prepared in many different ways. The five basic types of weld joints are the butt joint, lap joint, corner joint, edge joint, and T-joint (a variant of this last is the cruciform joint). Other variations exist as well - for example, double-V preparation joints are characterized by the two pieces of material each tapering to a single center point at one-half their height. Single-U and double-U preparation joints are also fairly common - instead of having straight edges like the single-V and double-V preparation joints, they are curved, forming the shape of a U. Lap joints are also commonly more than two pieces thick - depending on the process used and the thickness of the material, many pieces can be welded together in a lap joint geometry." [Welding. Wikipedia]

This engineering drawing example was redesigned using the ConceptDraw PRO diagramming and vector drawing software from the Wikimedia Commons file: Butt Weld Geometry.GIF.

[commons.wikimedia.org/ wiki/ File:Butt_ Weld_ Geometry.GIF]

The engineering drawing example "Butt weld geometry" is included in the Mechanical Engineering solution from the Engineering area of ConceptDraw Solution Park.

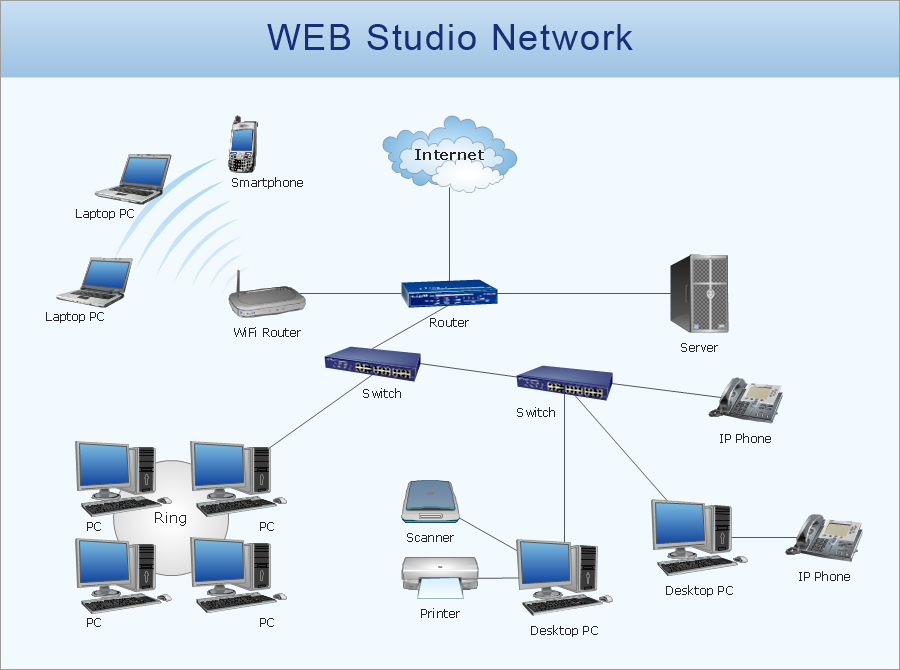

Network Diagram Software

Network Diagrams are used to visually represent the network architecture, to illustrate the network structure, how the computers and other elements of the network are connected each other using a variety of network symbols, clipart and connection lines. They are incredibly useful on the stages of projecting computer network, of its construction and exploitation. Professionally designed and accurate Network Diagrams are equally convenient for computer engineers and users. You can construct them by hand on the paper or use special network diagramming software, such as ConceptDraw DIAGRAM. Having at disposal the powerful network diagramming tools of Computer Network Diagrams solution included to ConceptDraw Solution Park, you can succeed in drawing various types of Computer Network Diagrams, among them Network Communication Plans, Logical Network Diagrams, Network Topology Diagrams, LAN and WAN Diagrams, Network Floor Plan Layouts, Computer Network System Diagrams, Web-based Network Diagrams, Wireless Network Diagrams, Cisco Network Diagram, and others.

HelpDesk

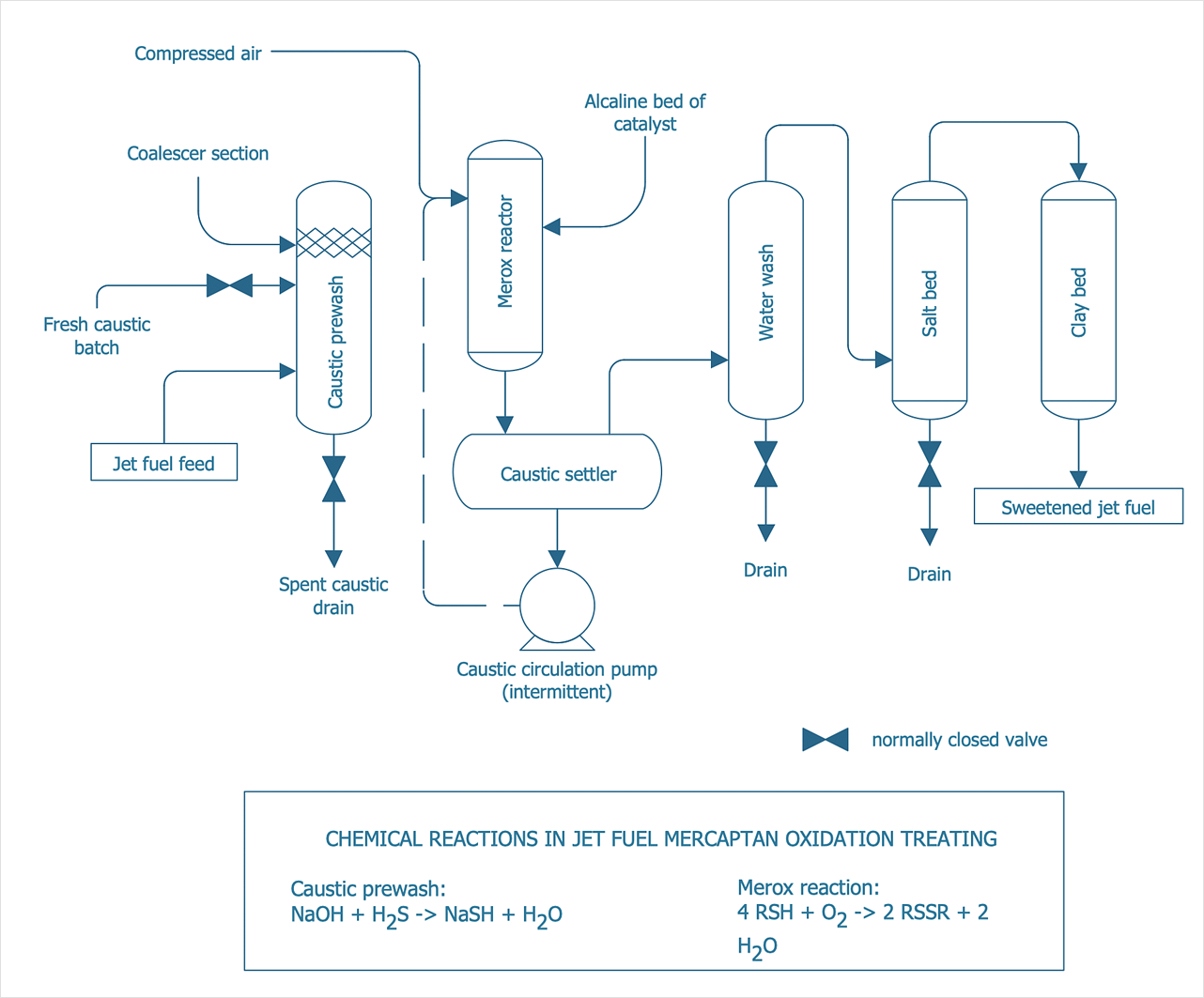

How to Draw a Chemical Process Flow Diagram

Process Flow Diagram widely used in modeling of processes in the chemical industry. A Chemical Process Flow diagram (PFD) is a specialized type of flowchart. With the help of Chemical Process Flow Diagram engineers can easily specify the general scheme of the processes and chemical plant equipment. Chemical Process Flow Diagram displays the real scheme of the chemical process, the relationship between the equipment and the technical characteristics of the process. Chemical Process Flow Diagram illustrates the connections between the basic equipment as well as the overall structure of pipelines and other supporting equipment. The purpose of the PFD is to build the image of the basic idea of the chemical process. ConceptDraw DIAGRAM together with its Chemical and Process Engineering solution delivers the possibility to design Chemical Process Flow diagrams. It is designed for chemical industry engineers and designers.- Mechanical Engineering | Mechanical Drawing Symbols ...

- Electrical Wiring Diagram Software Gif

- Hydraulic schematic | Bank ATM use case diagram | Basic Flowchart ...

- A Diagram Of AT Joint

- Butt weld geometry | Butt weld geometry | Mechanical Engineering ...

- How To Create CCTV Network Diagram | Rotation Gif

- Circuit diagram - EL 34 schematics | International Gif

- Diagram Of T Joint Welding

- Butt weld geometry | Mechanical Engineering | Mechanical Drawing ...

- Butt weld geometry | Mechanical Engineering | Diagram Of Five ...

- Types Of Welding With Diagram

- Butt weld geometry | Mechanical Engineering | Diagram For Various ...

- Welded joints types | Mechanical Engineering | Butt weld geometry ...

- Diagrams Of Welded Joint Joints

- Butt weld geometry | Mechanical Engineering | Show The Diagram ...

- Butt weld geometry | Mechanical Engineering | Mechanical Drawing ...

- Butt weld geometry | Mechanical Engineering | Interior Design ...

- Butt weld geometry | Mechanical Engineering | Welding symbols ...

- Butt weld geometry | Mechanical Engineering | Design elements ...