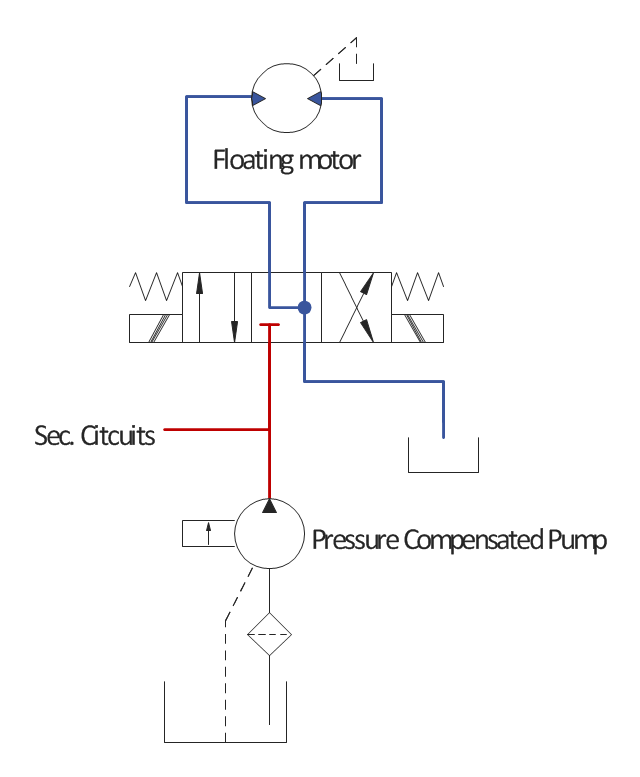

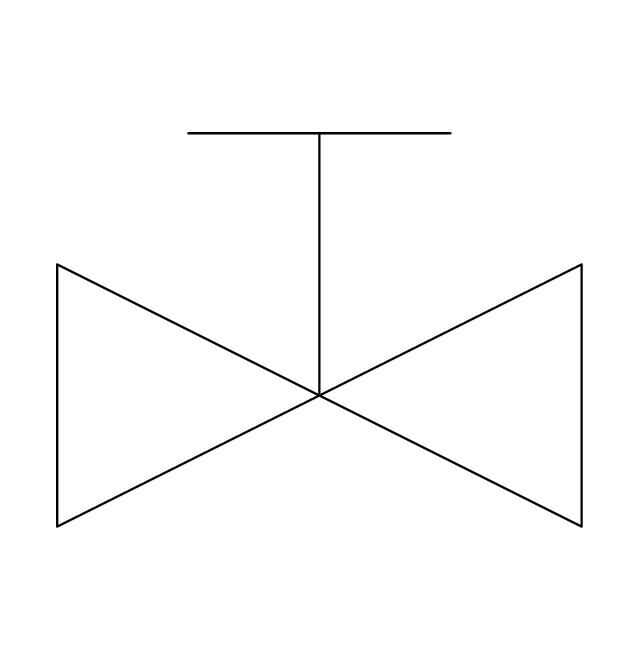

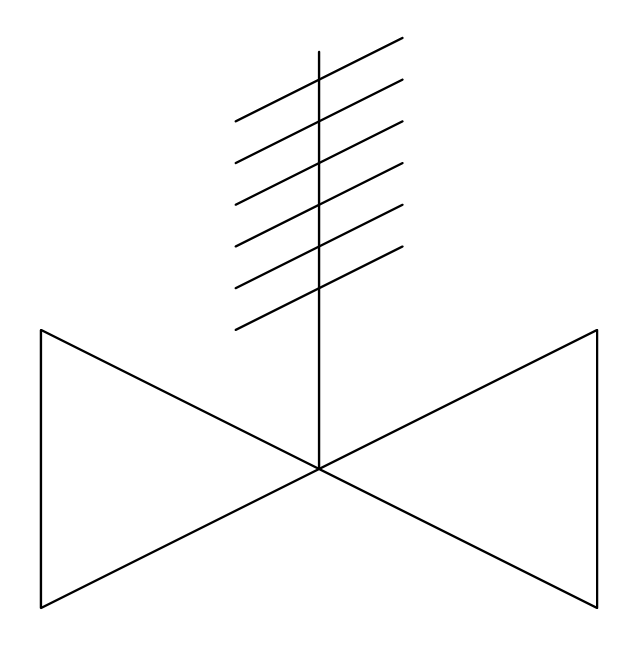

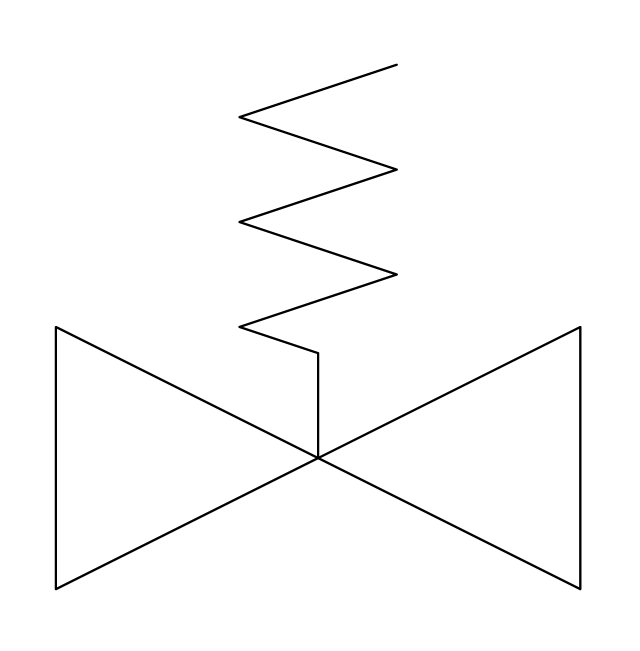

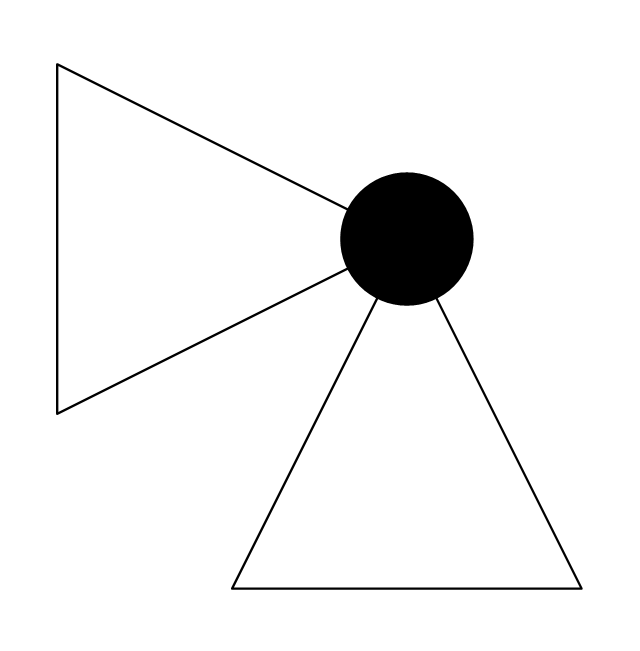

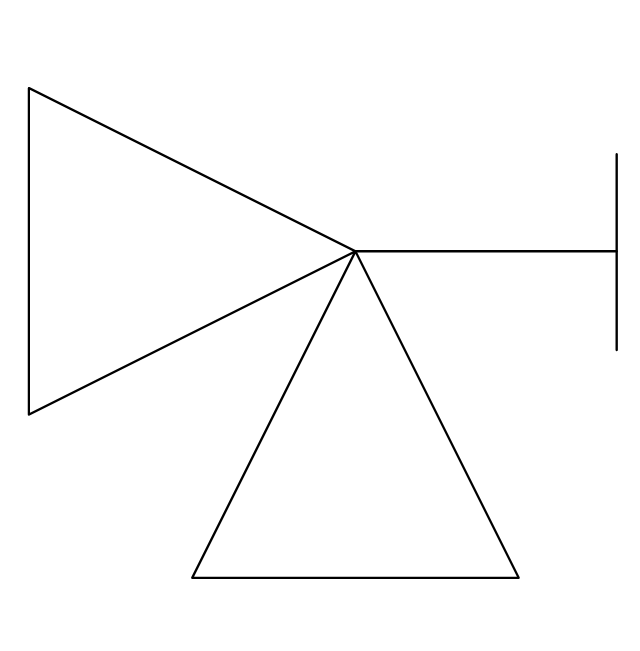

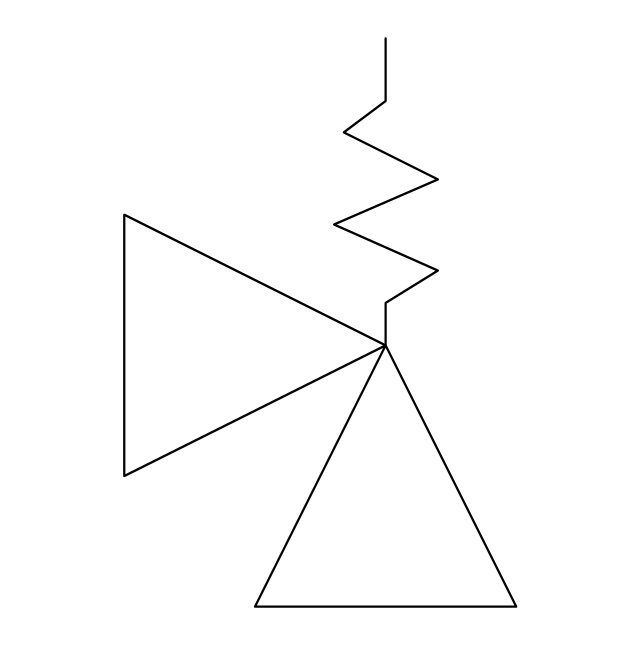

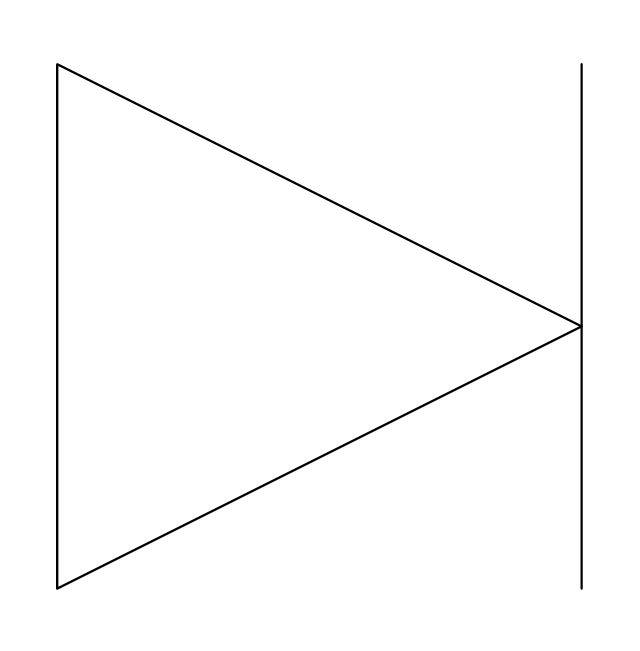

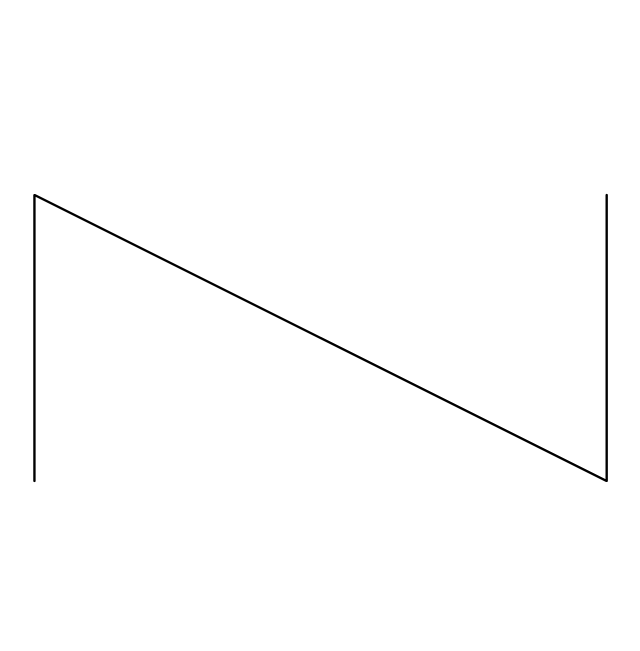

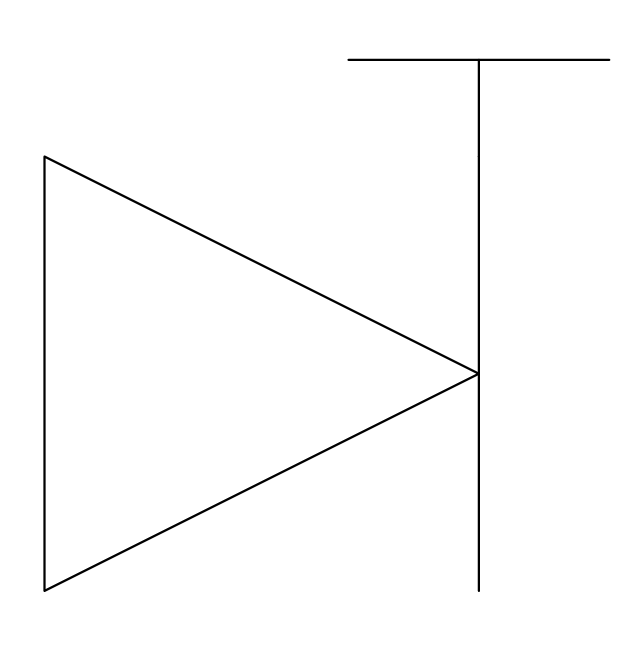

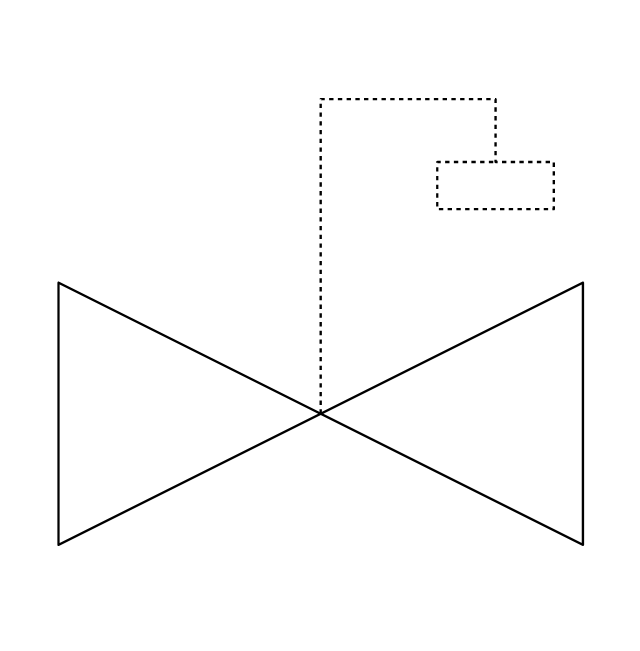

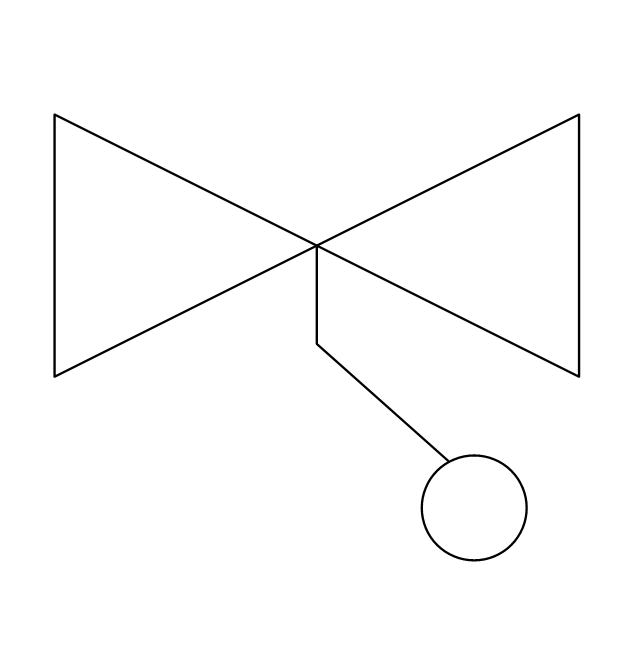

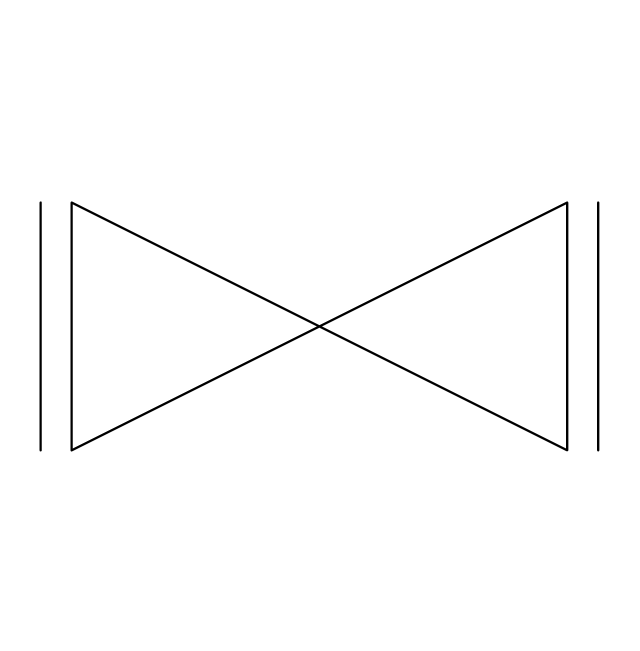

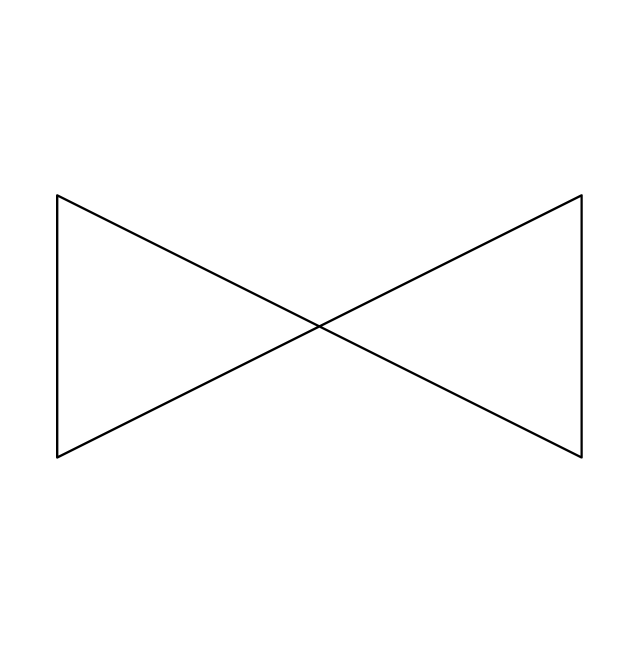

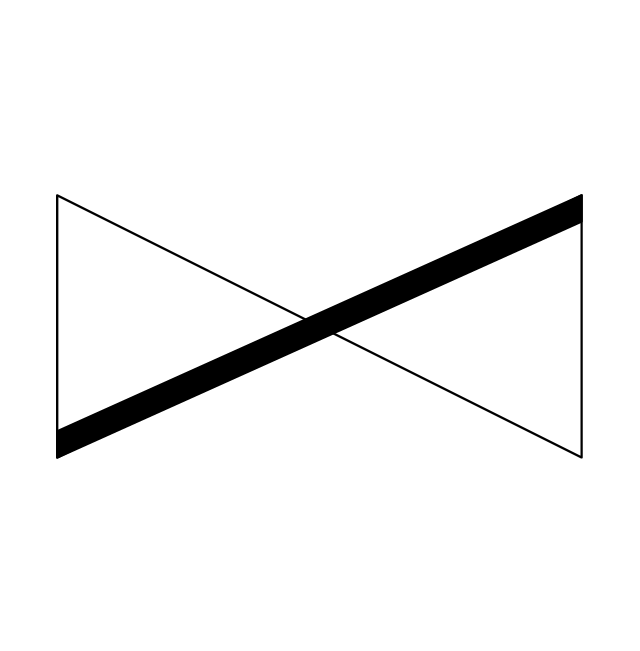

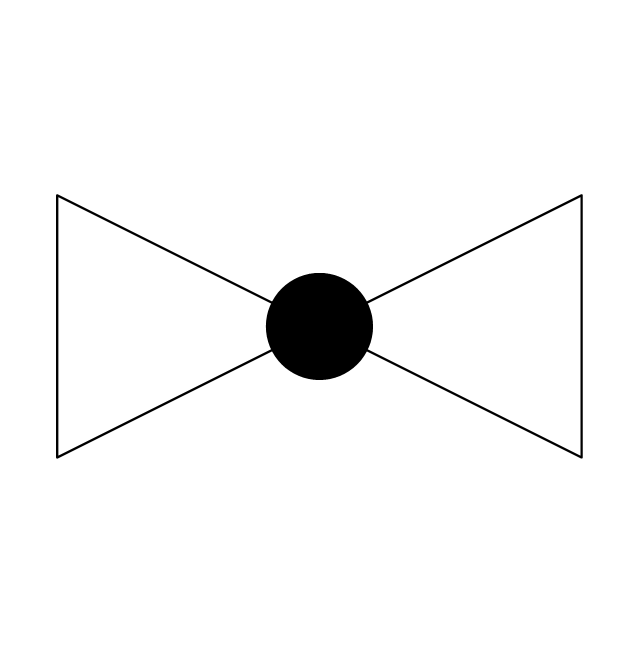

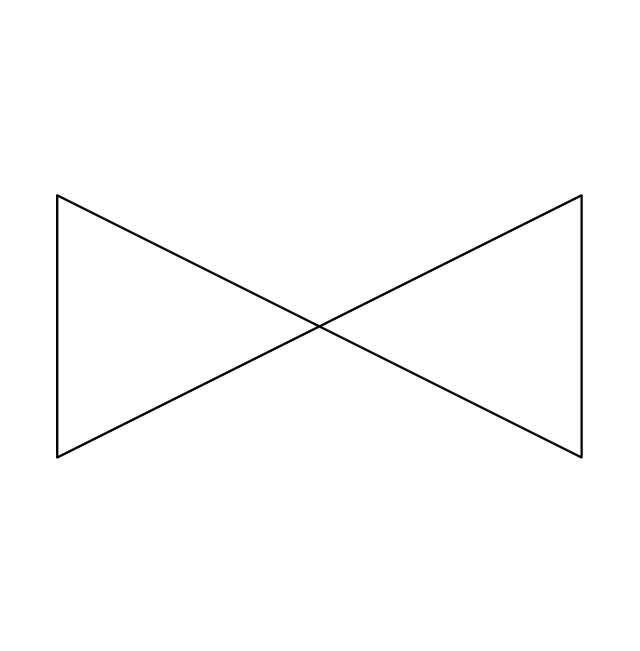

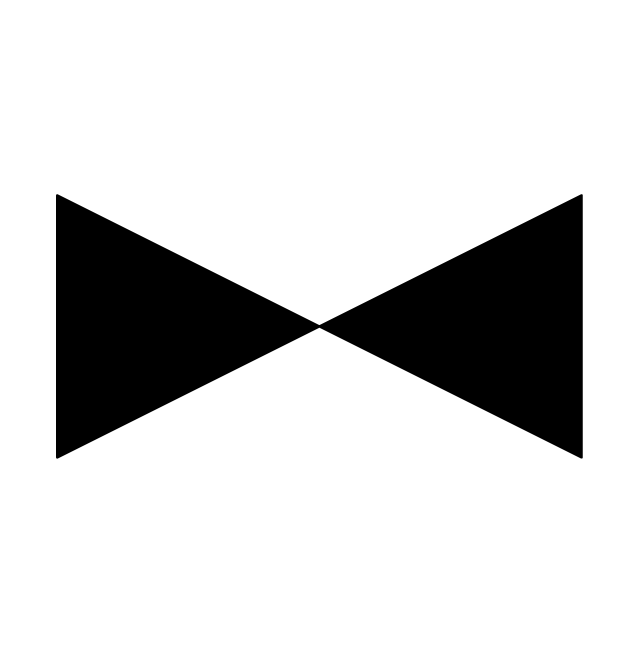

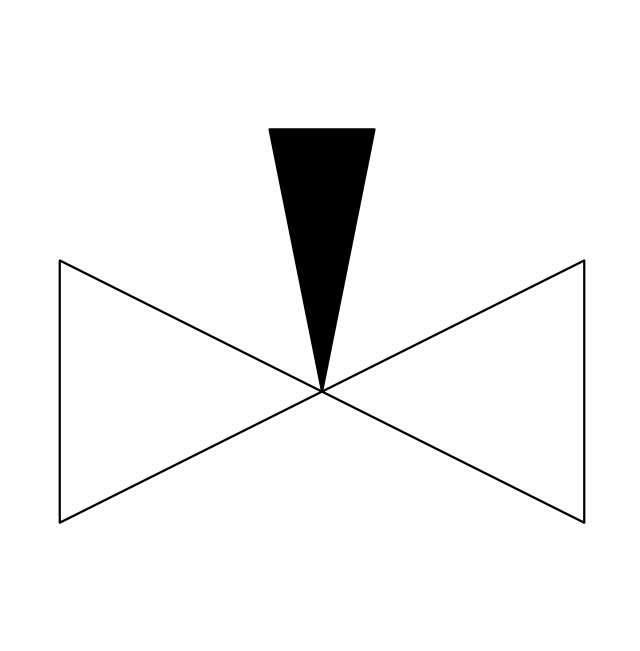

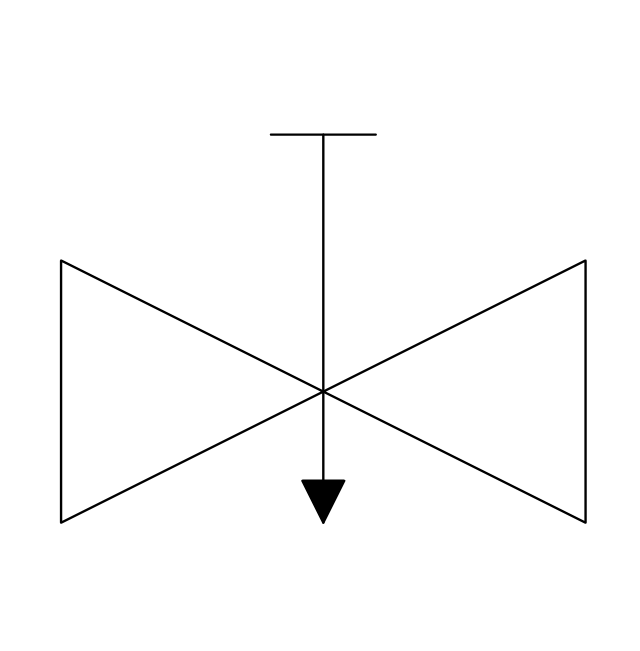

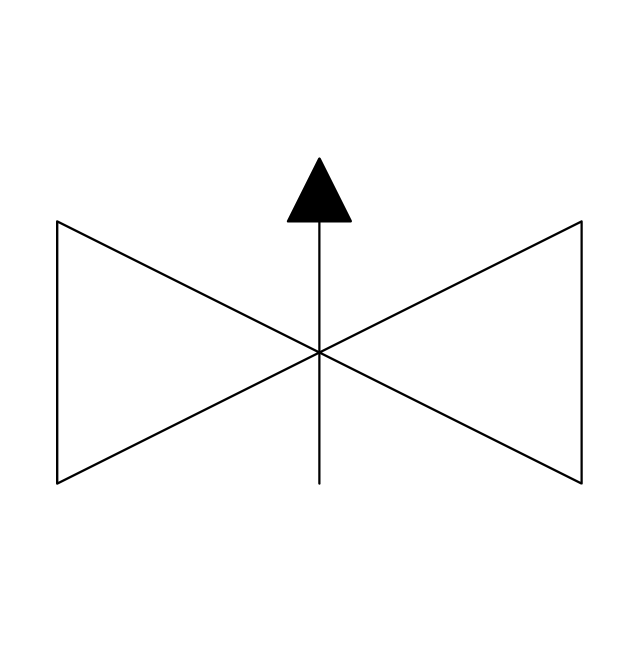

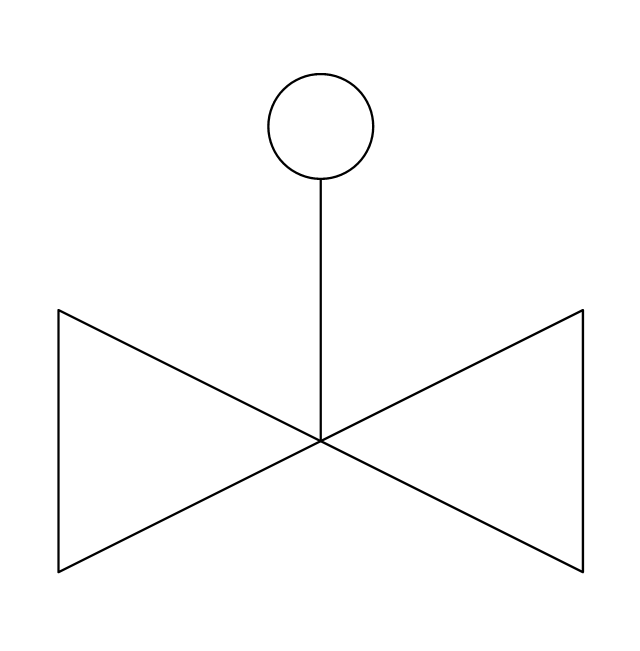

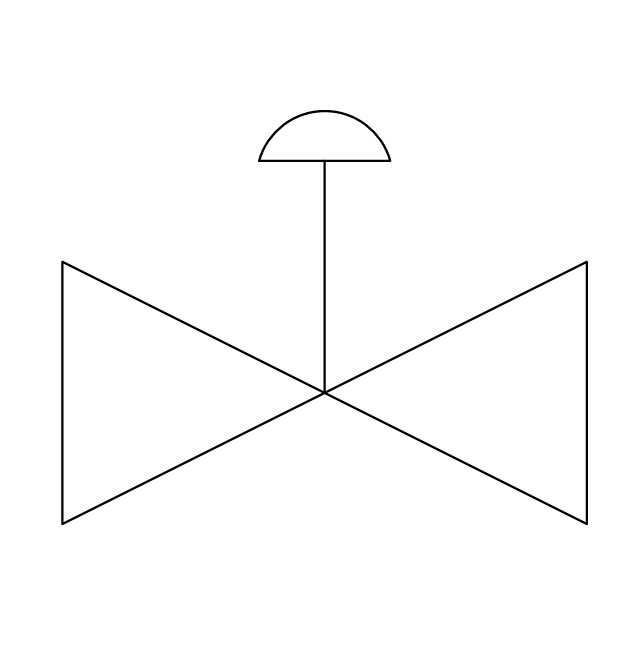

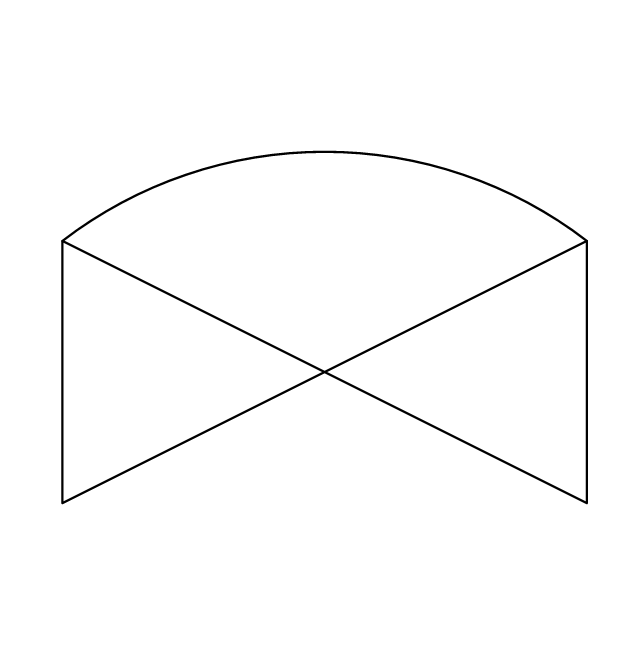

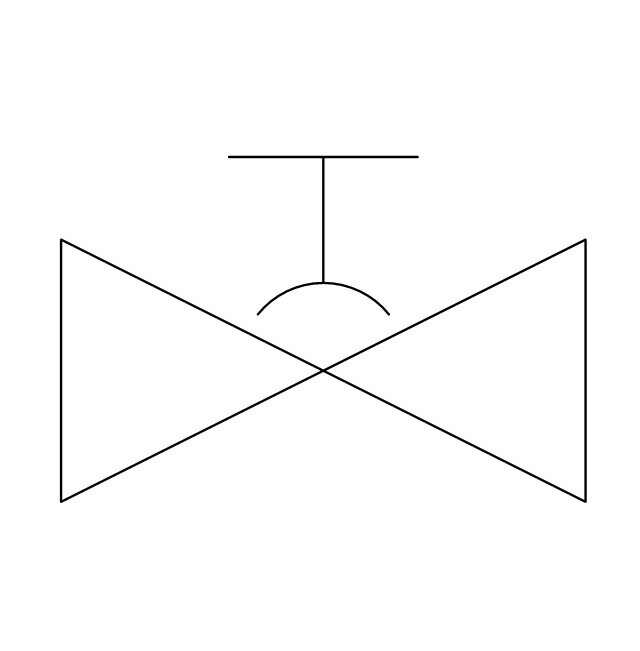

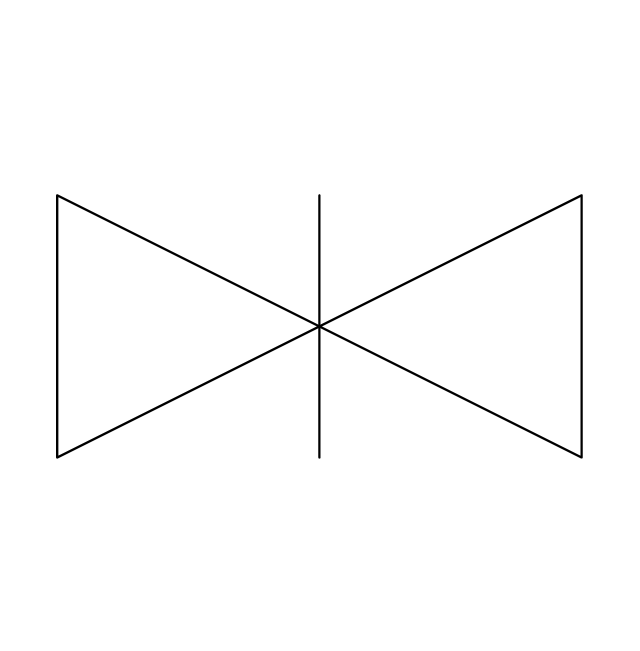

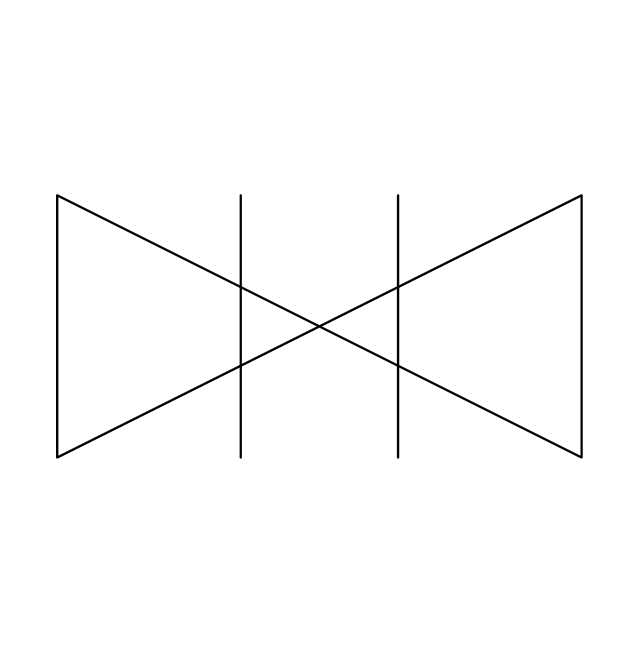

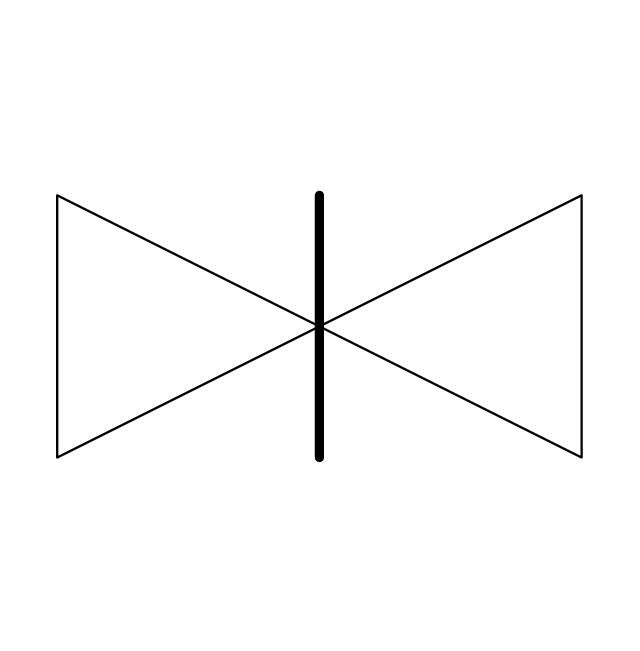

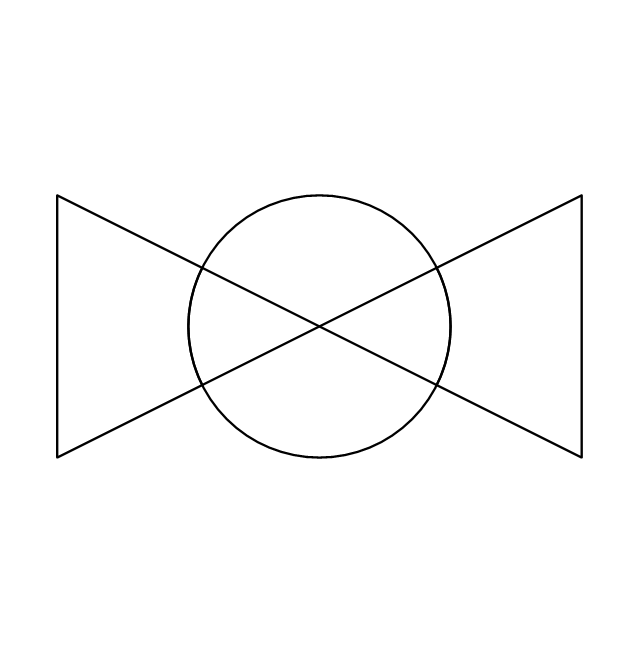

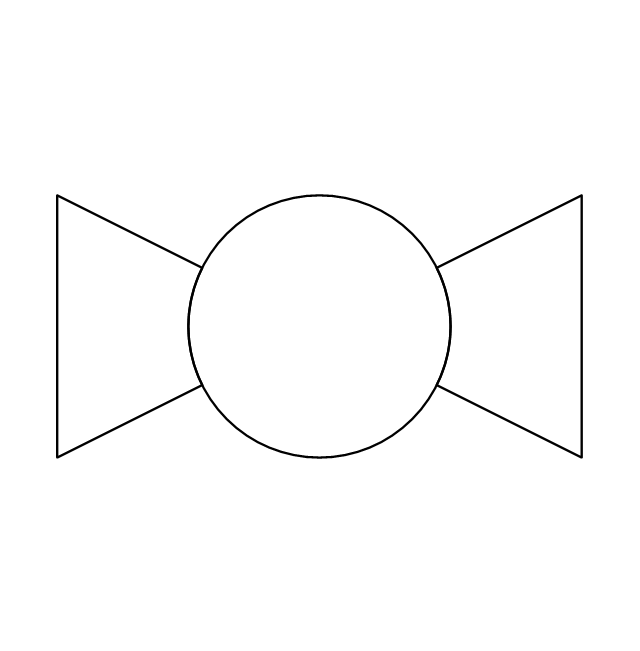

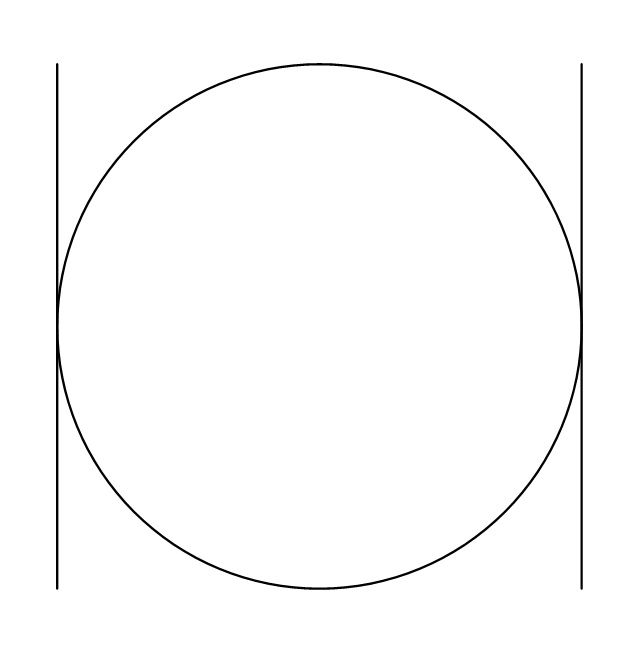

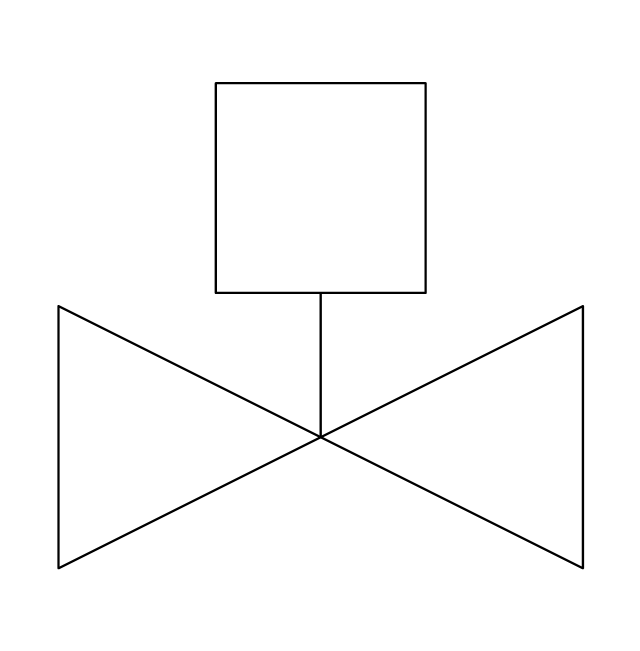

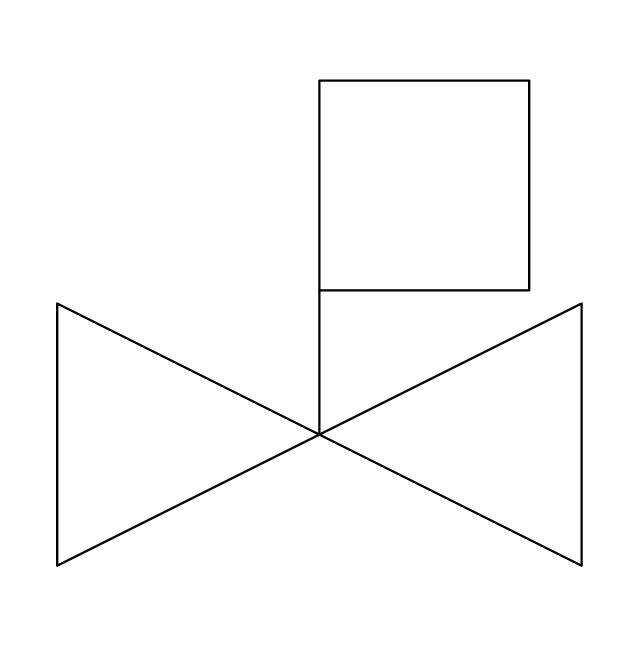

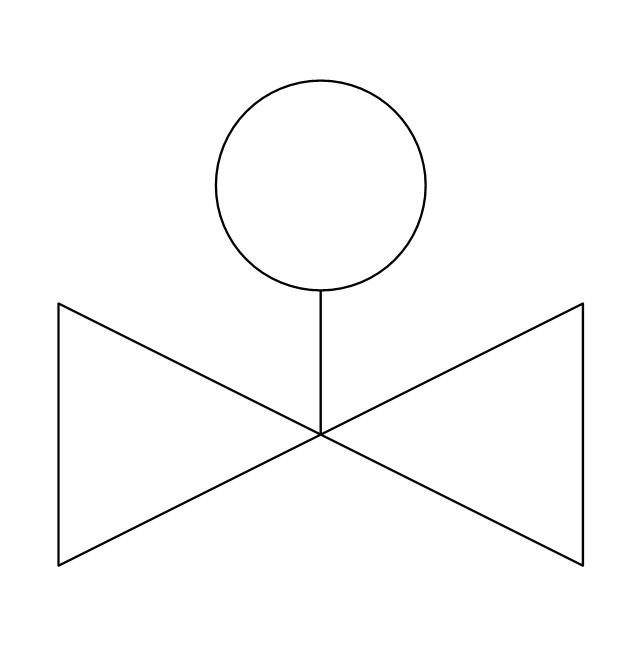

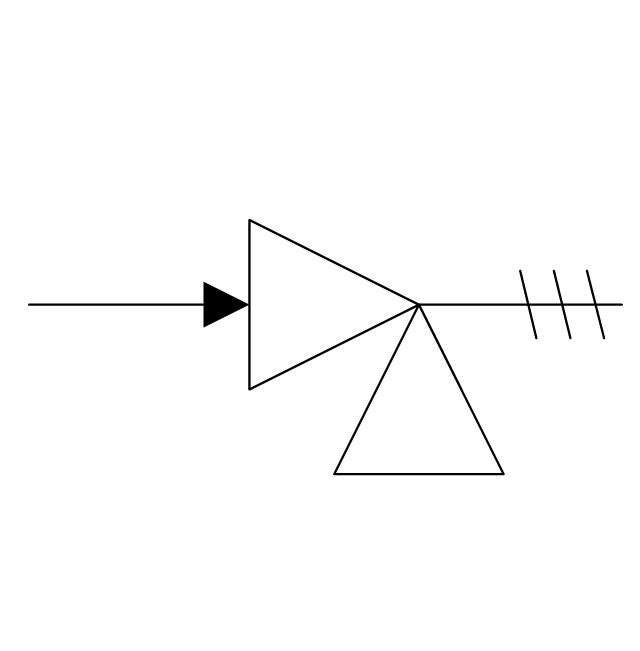

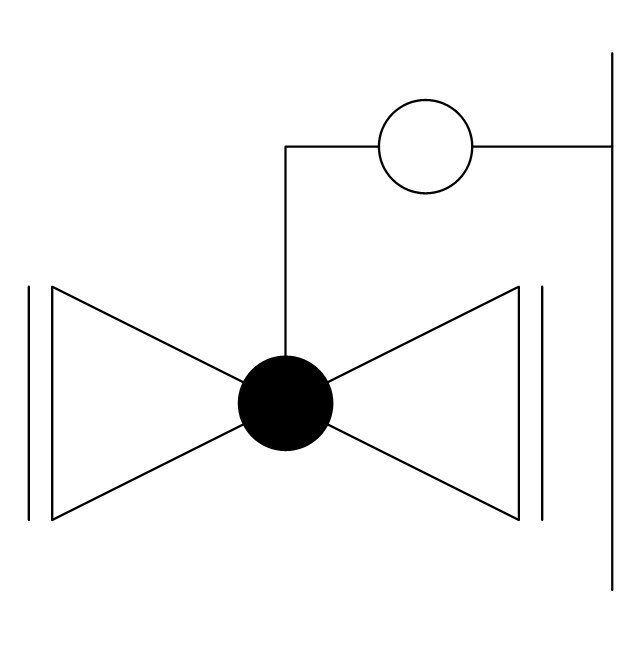

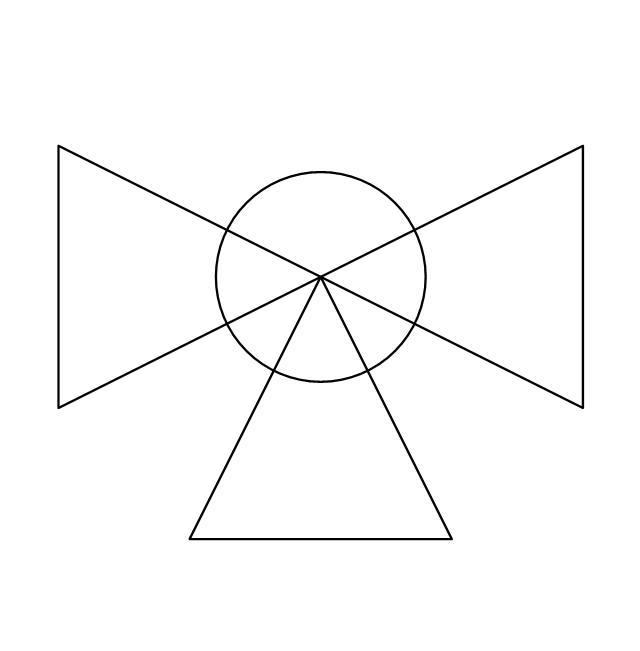

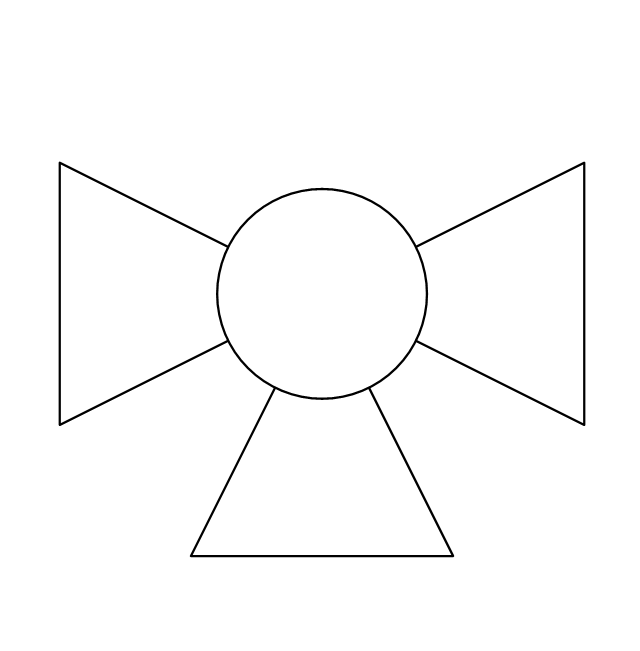

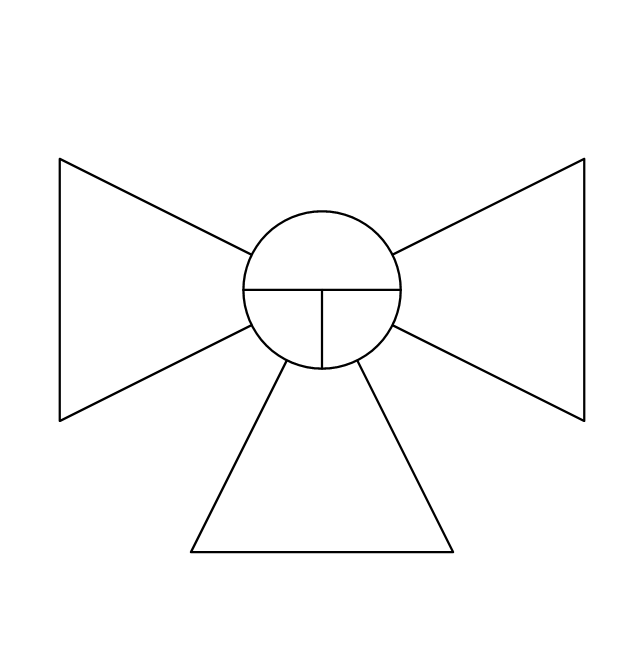

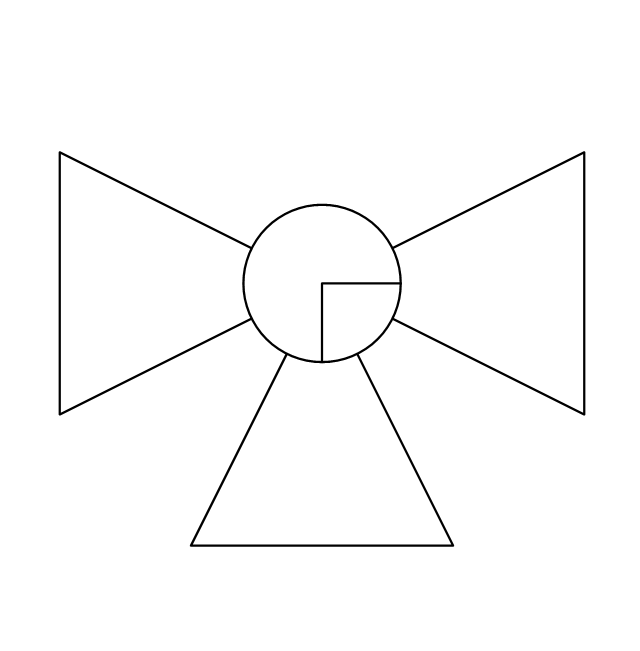

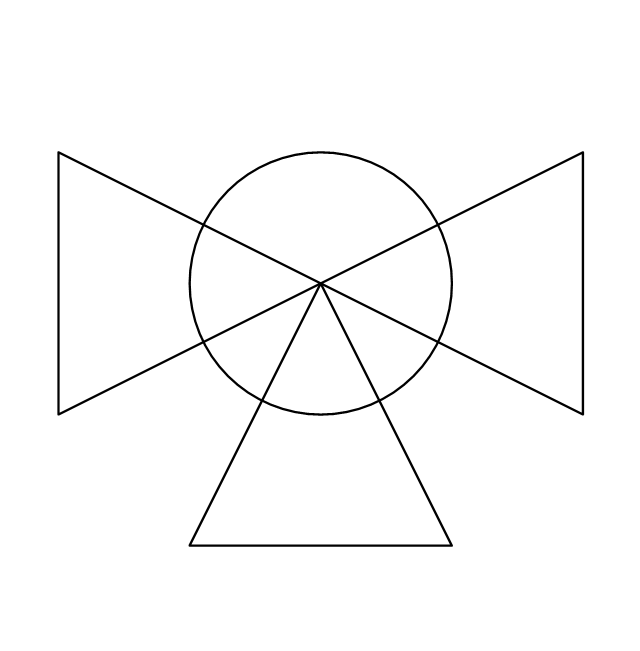

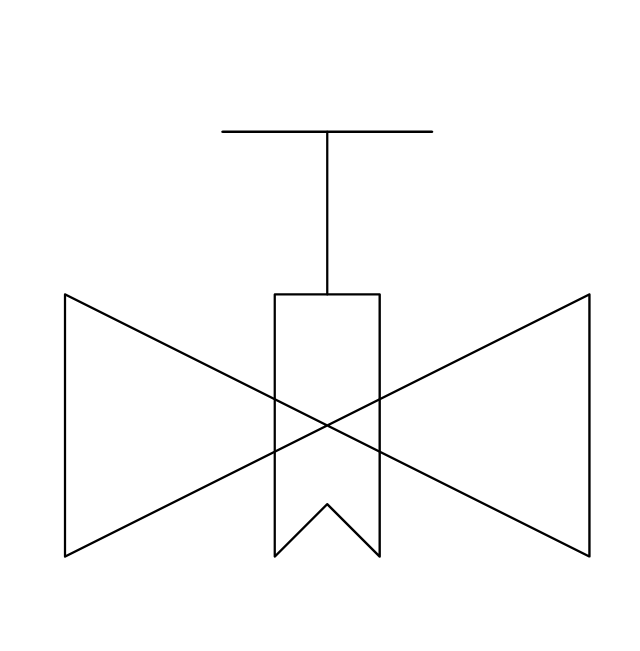

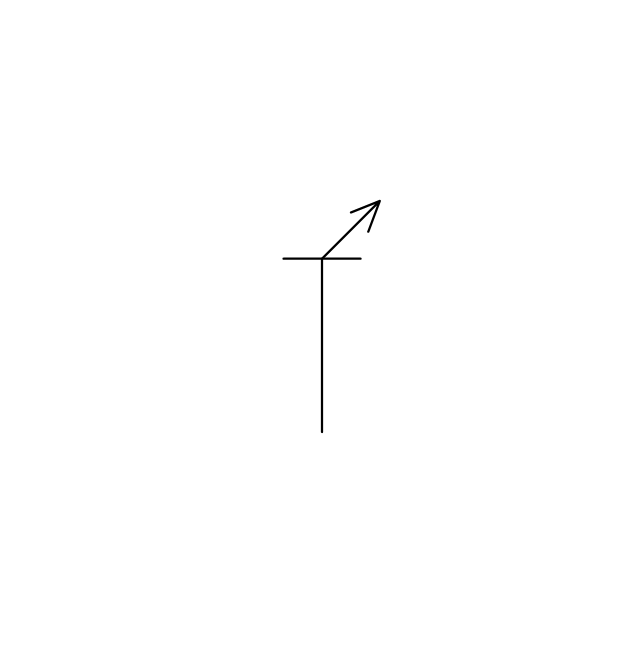

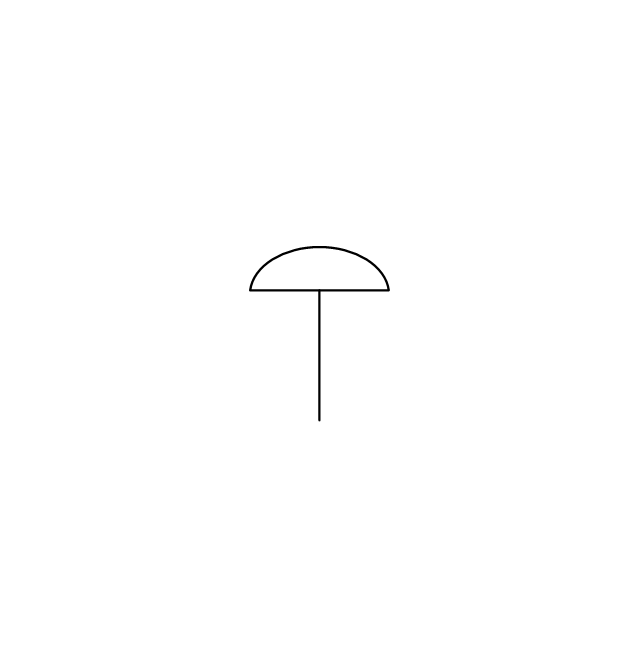

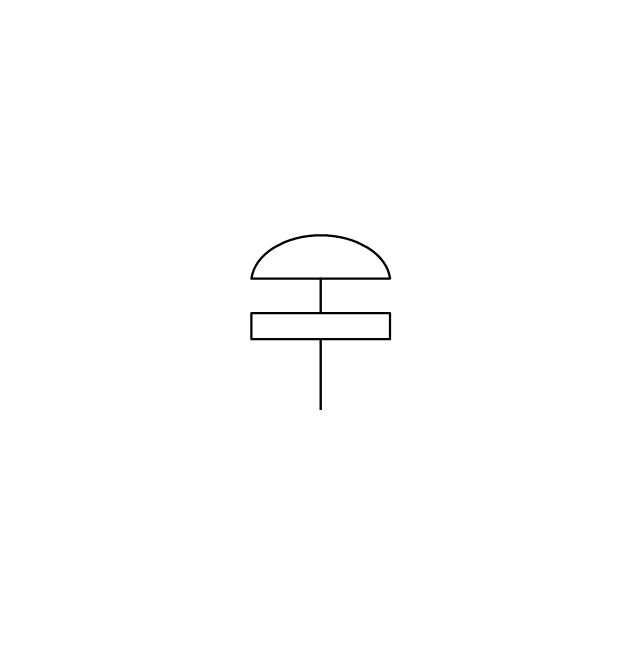

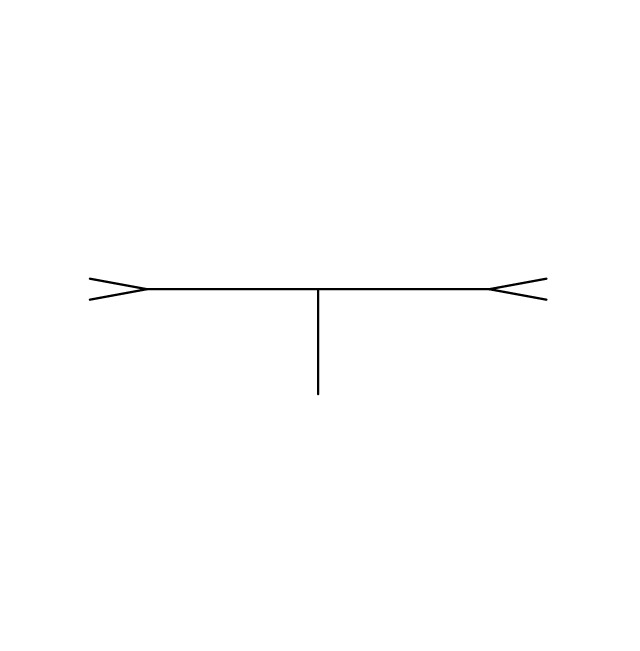

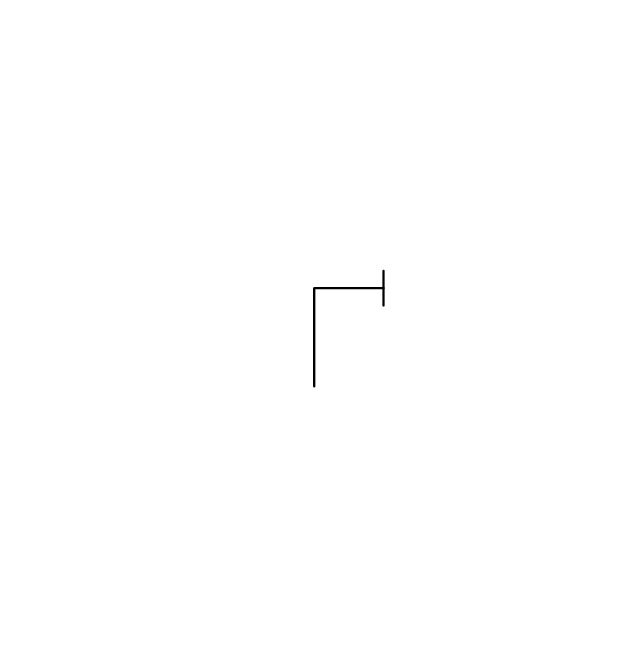

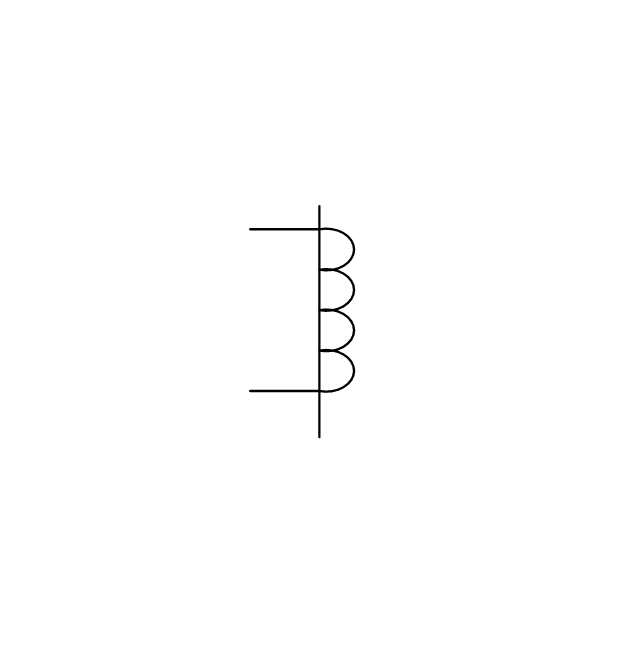

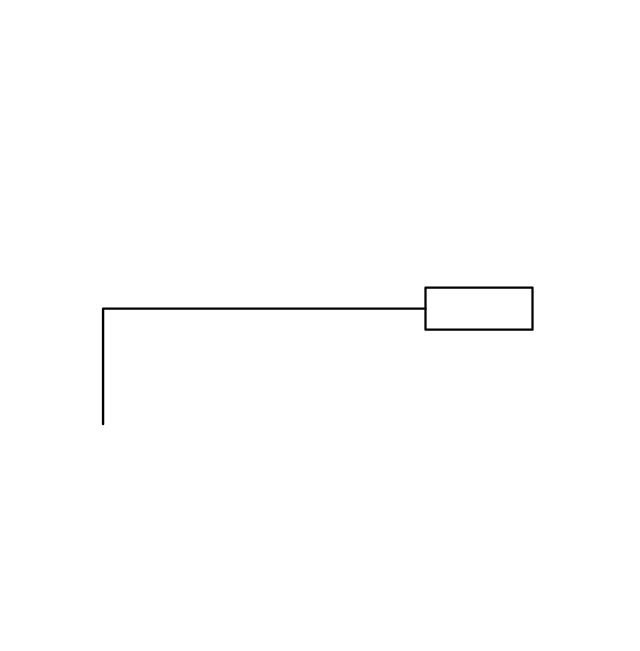

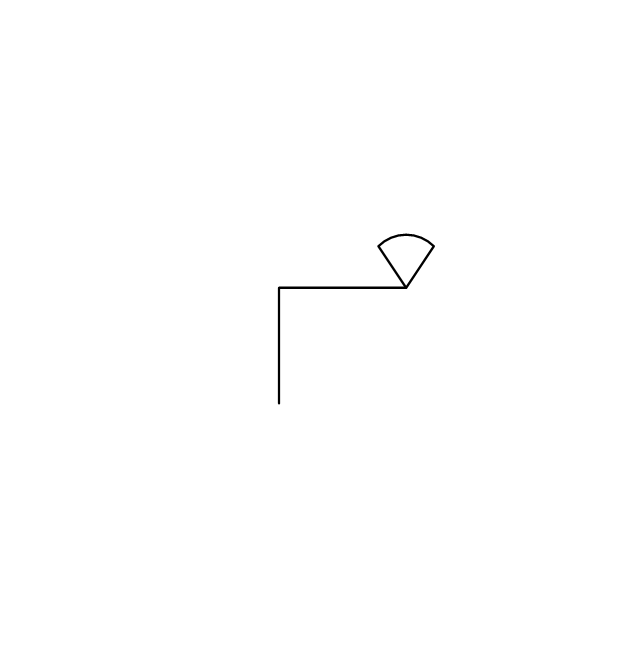

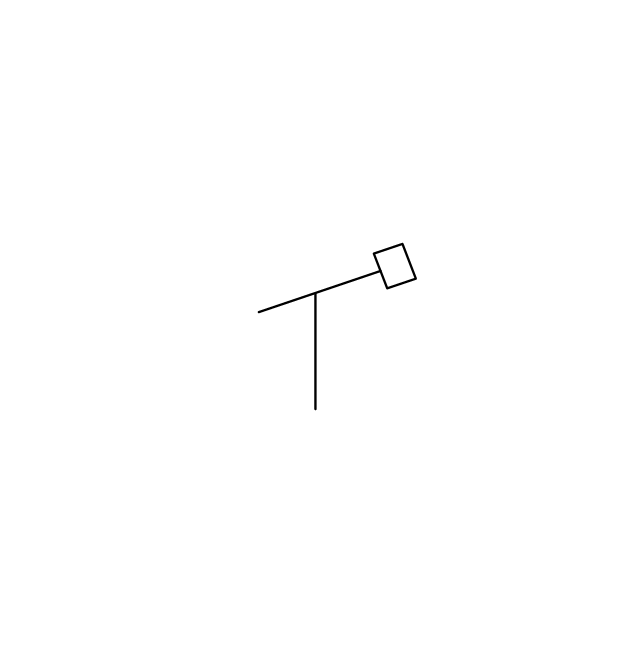

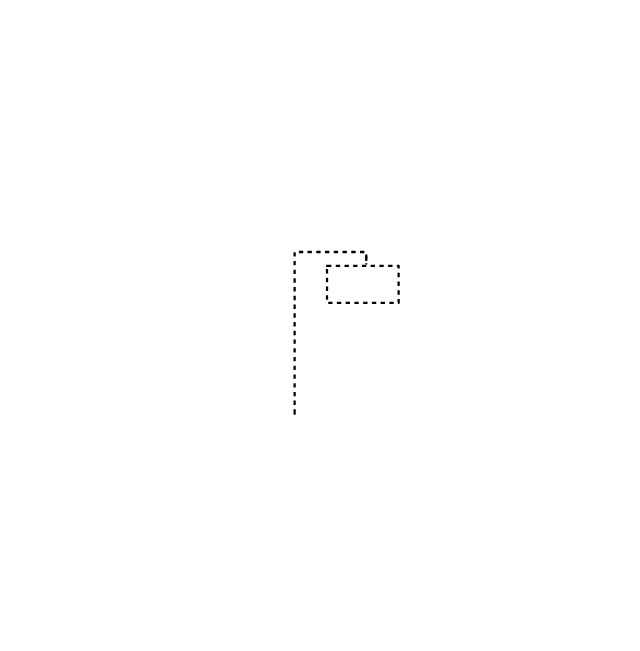

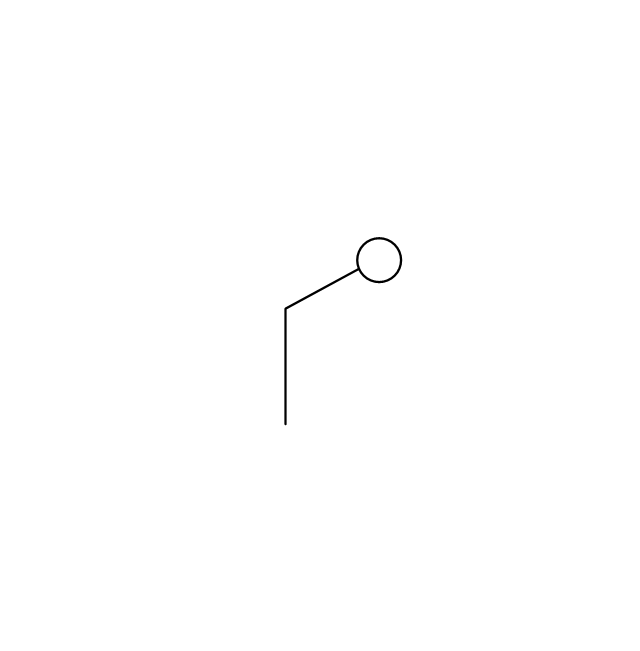

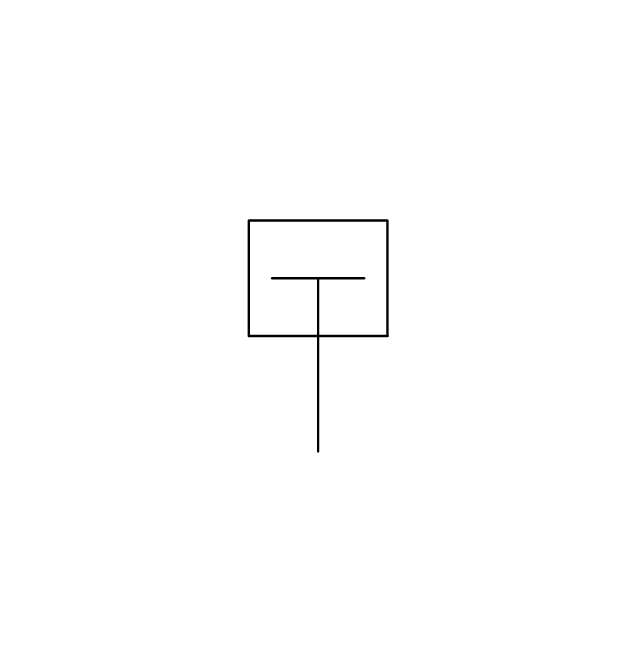

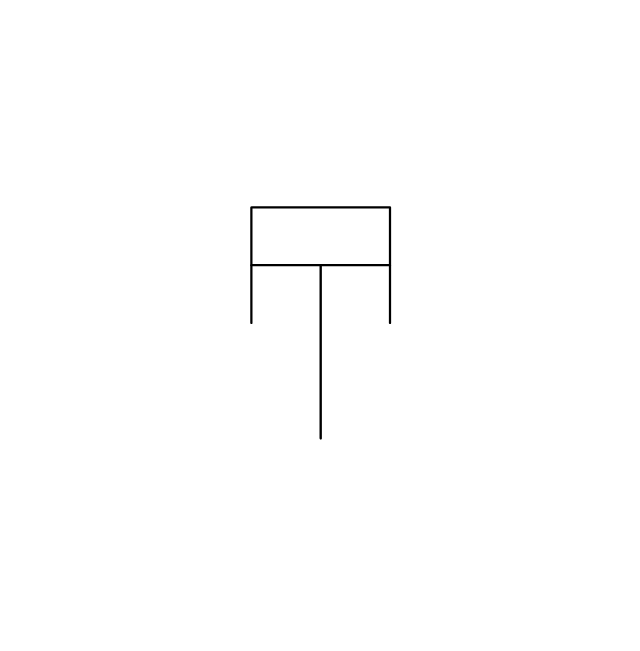

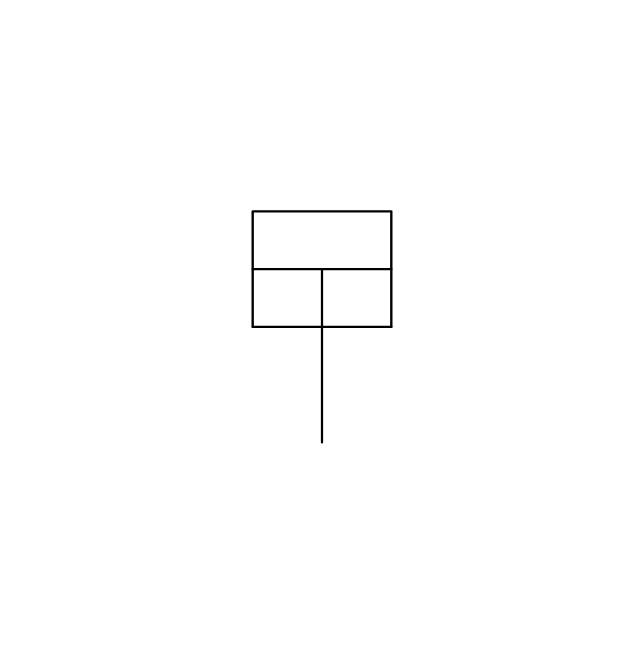

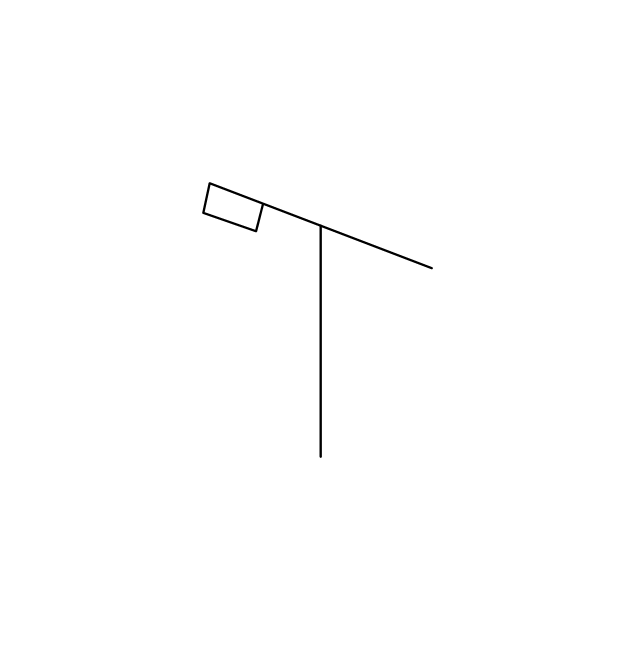

This example engineering drawing showing the hydraulic directional control valve usage with floating motor and pressure compensated pump is redesigned using the ConceptDraw PRO diagramming and vector drawing software from the Wikimedia Commons file: DCV 17.jpg.

[commons.wikimedia.org/ wiki/ File:DCV_ 17.jpg]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license.

[creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

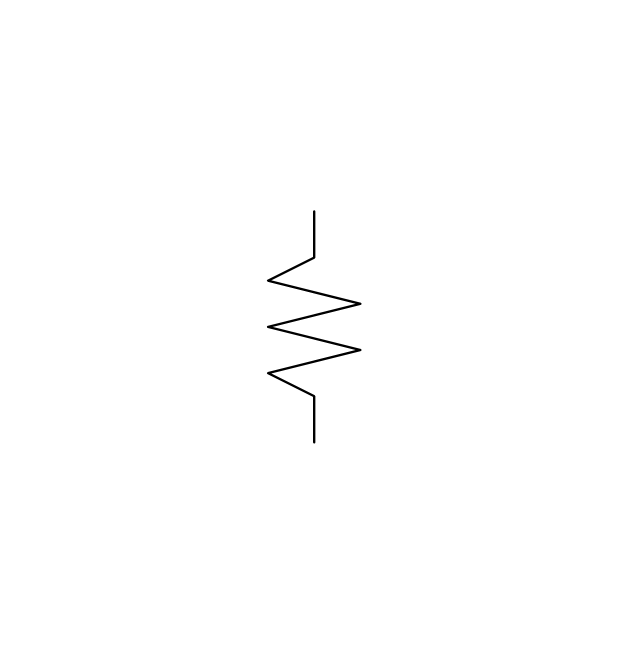

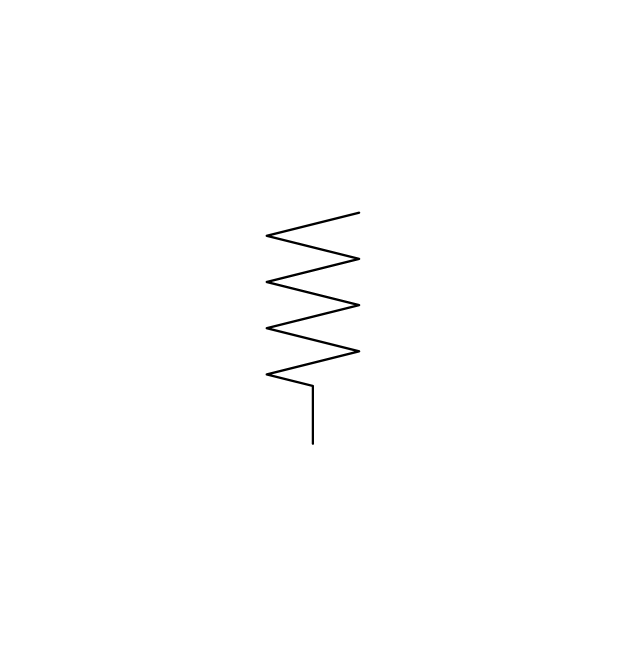

"Directional control valves are one of the most fundamental parts in hydraulic machinery as well and pneumatic machinery. They allow fluid flow into different paths from one or more sources. They usually consist of a spool inside a cylinder which is mechanically or electrically controlled. The movement of the spool restricts or permits the flow, thus it controls the fluid flow. ...

The spool (sliding type) consists of lands and grooves.The lands block oil flow through the valve body. The grooves allow oil or gas to flow around the spool and through the valve body. There are two fundamental positions of directional control valve namely normal position where valve returns on removal of actuating force and other is working position which is position of a valve when actuating force is applied. There is another class of valves with 3 or more position that can be spring centered with 2 working position and a normal position. ...

Directional control valves can be classified according to:

(1) number of ports;

(2) number of positions;

(3) actuating methods;

(4) type of spool." [Directional control valve. Wikipedia]

The fluid power equipment drawing example "Directional control valve" is included in the Mechanical Engineering solution from the Engineering area of ConceptDraw Solution Park.

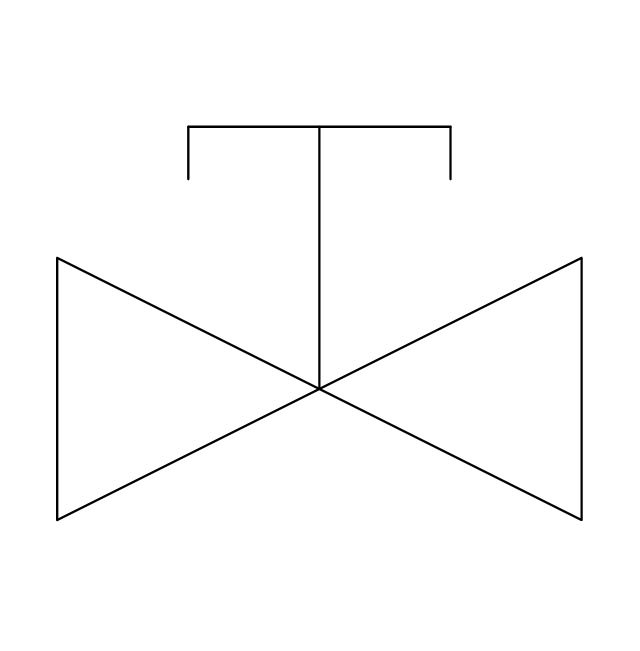

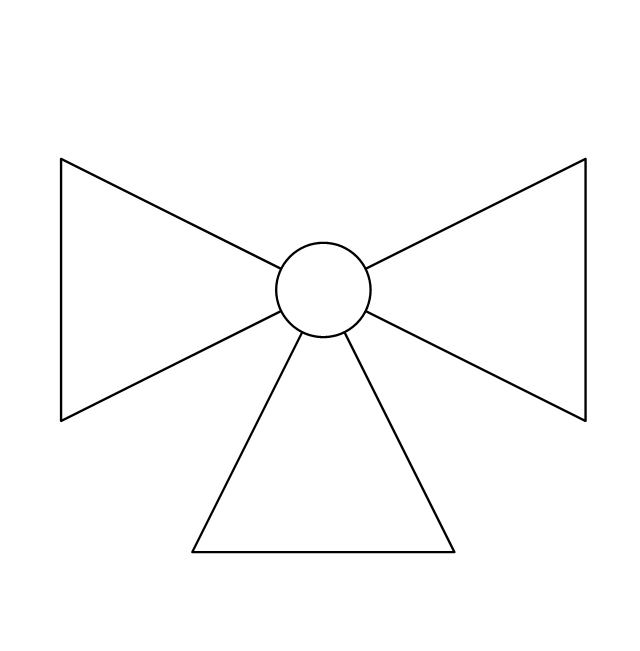

[commons.wikimedia.org/ wiki/ File:DCV_ 17.jpg]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license.

[creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"Directional control valves are one of the most fundamental parts in hydraulic machinery as well and pneumatic machinery. They allow fluid flow into different paths from one or more sources. They usually consist of a spool inside a cylinder which is mechanically or electrically controlled. The movement of the spool restricts or permits the flow, thus it controls the fluid flow. ...

The spool (sliding type) consists of lands and grooves.The lands block oil flow through the valve body. The grooves allow oil or gas to flow around the spool and through the valve body. There are two fundamental positions of directional control valve namely normal position where valve returns on removal of actuating force and other is working position which is position of a valve when actuating force is applied. There is another class of valves with 3 or more position that can be spring centered with 2 working position and a normal position. ...

Directional control valves can be classified according to:

(1) number of ports;

(2) number of positions;

(3) actuating methods;

(4) type of spool." [Directional control valve. Wikipedia]

The fluid power equipment drawing example "Directional control valve" is included in the Mechanical Engineering solution from the Engineering area of ConceptDraw Solution Park.

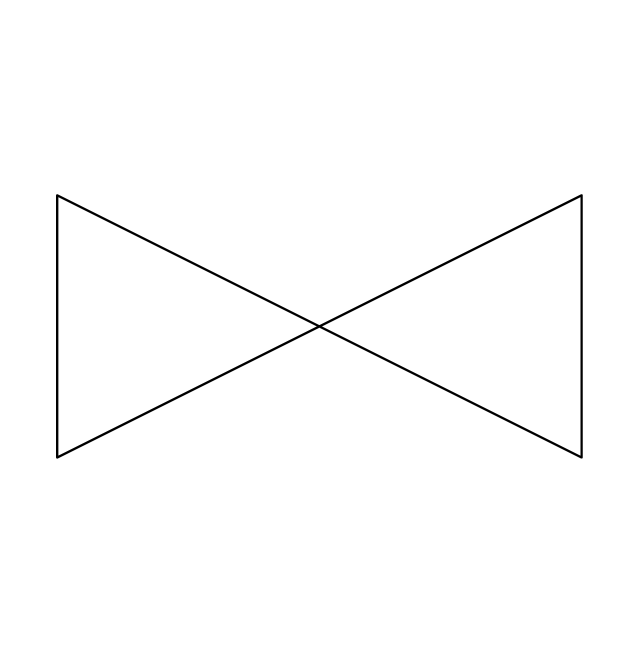

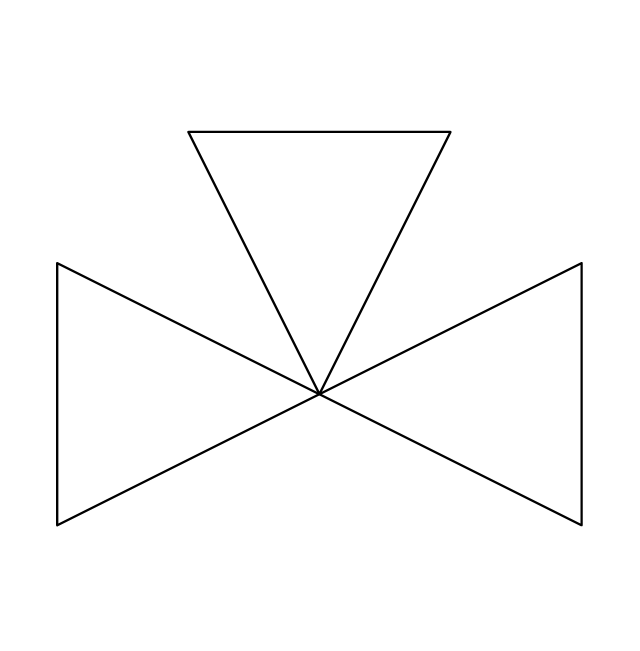

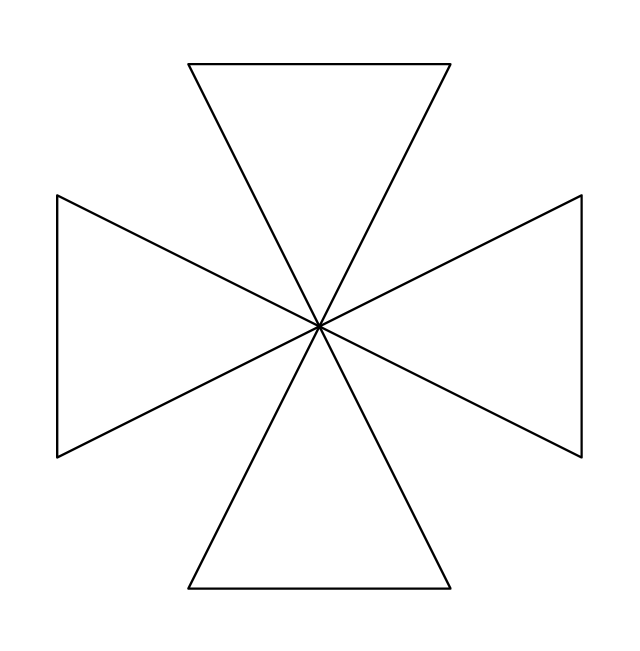

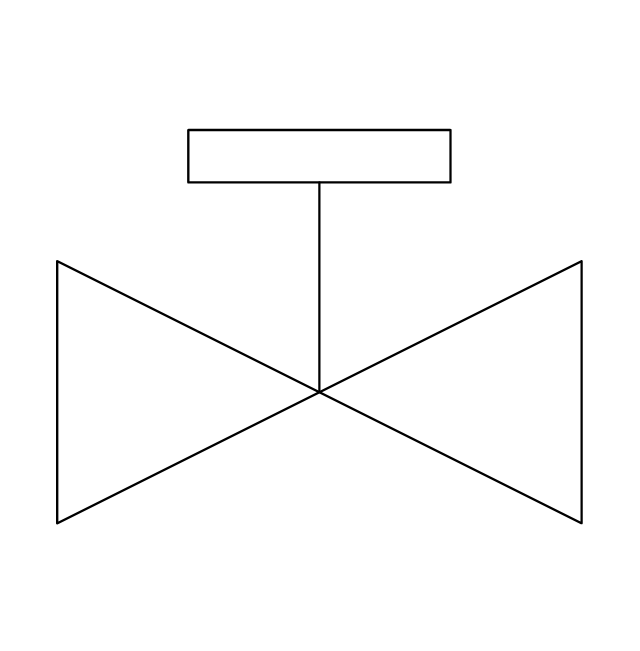

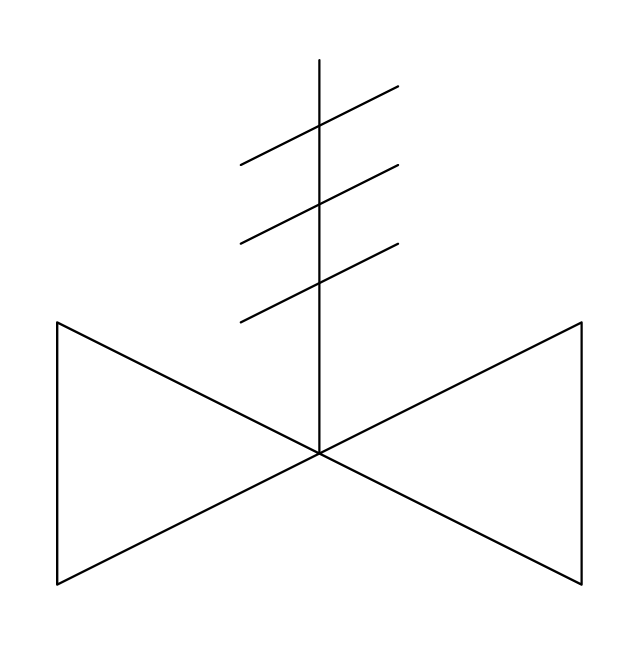

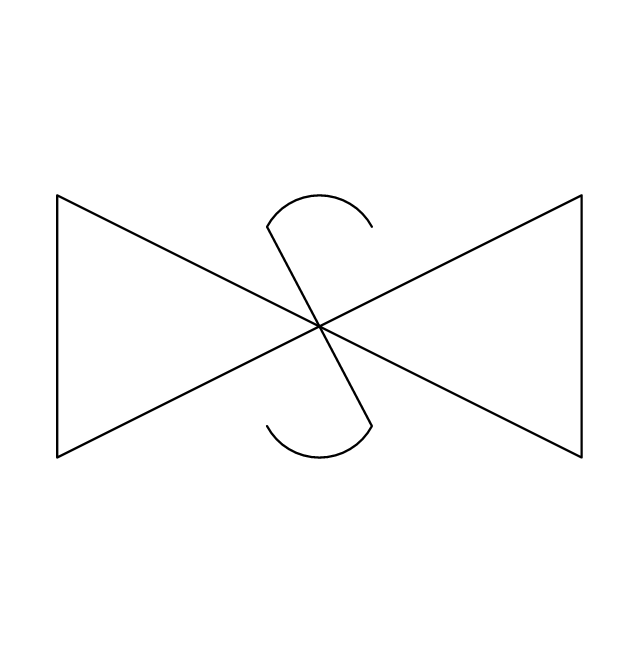

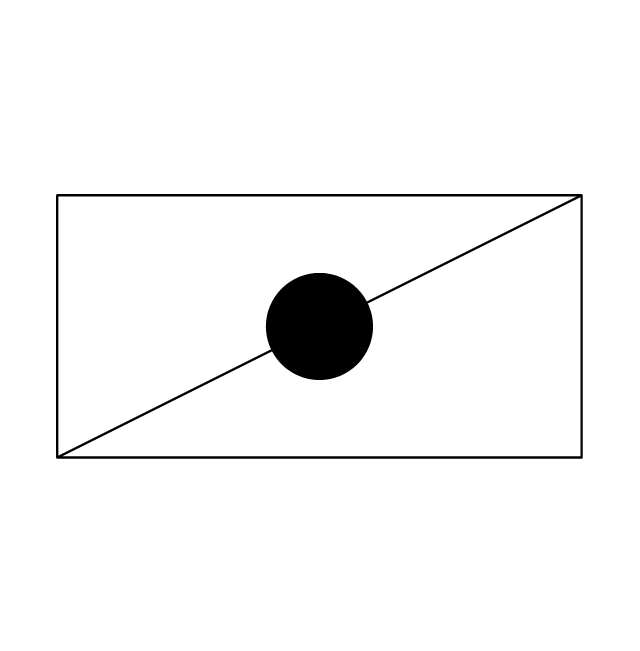

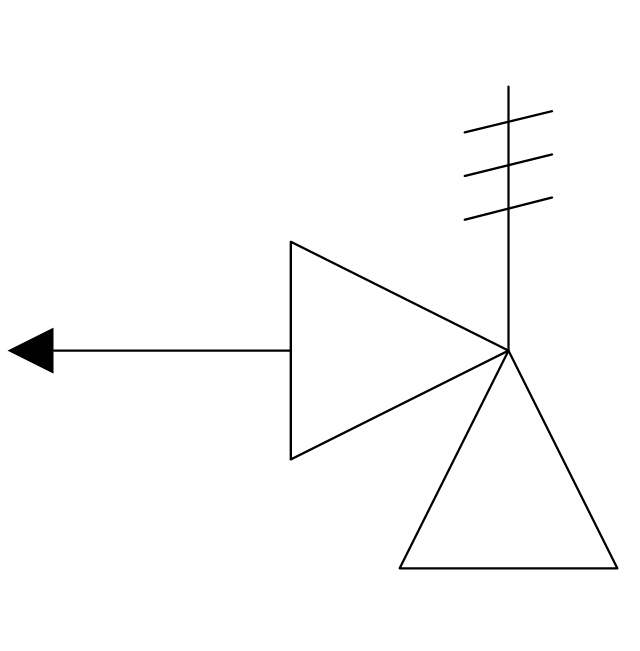

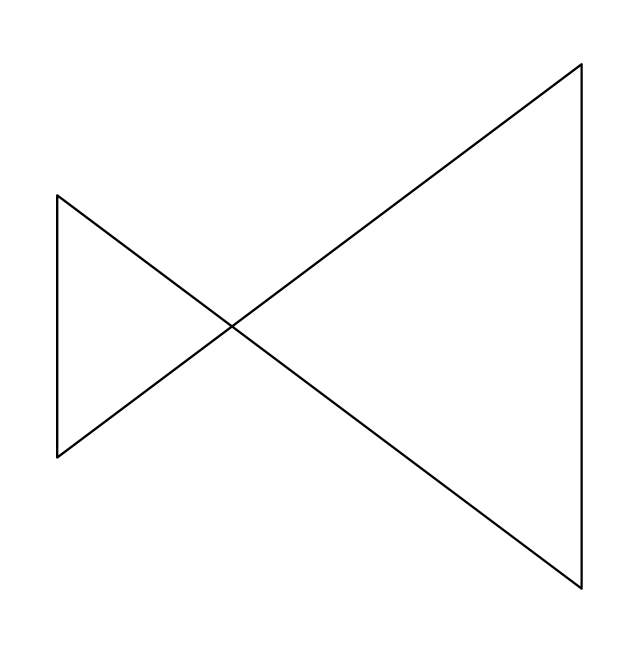

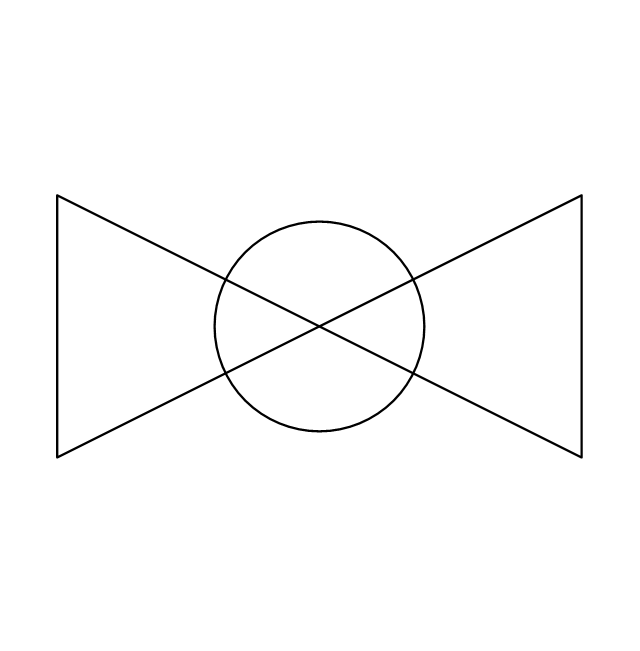

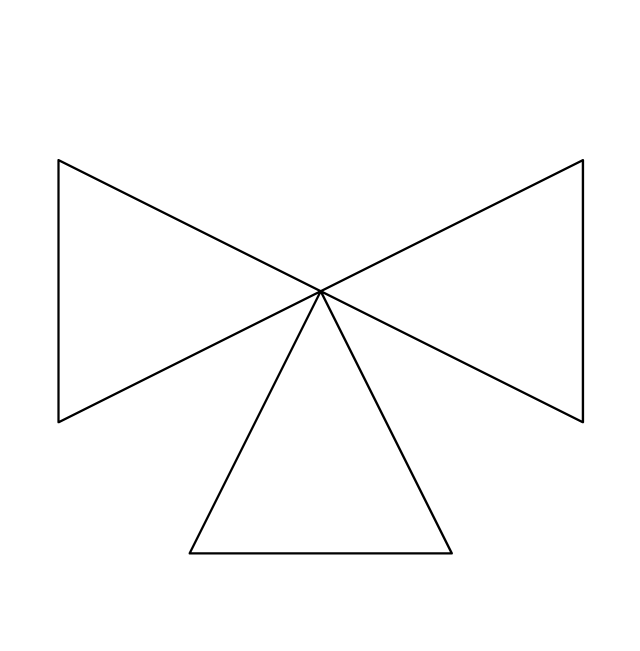

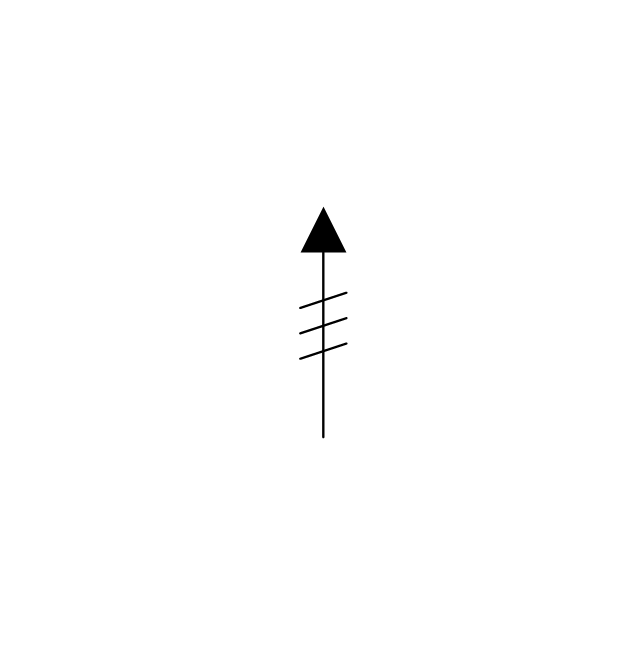

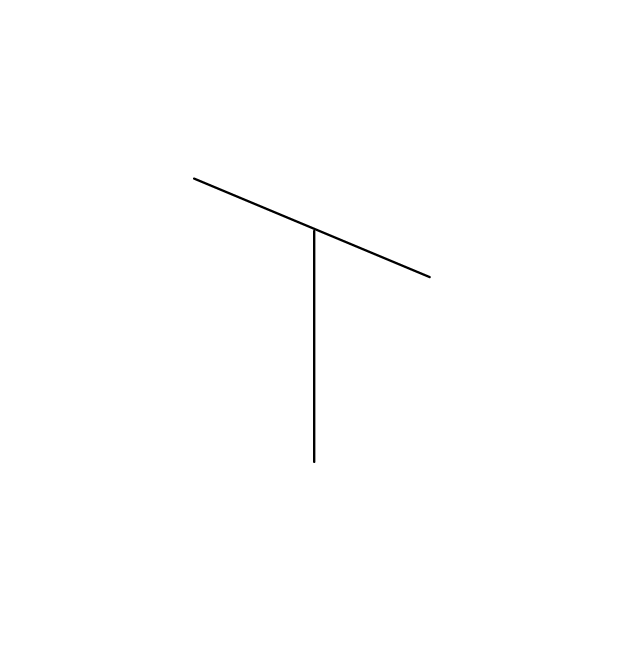

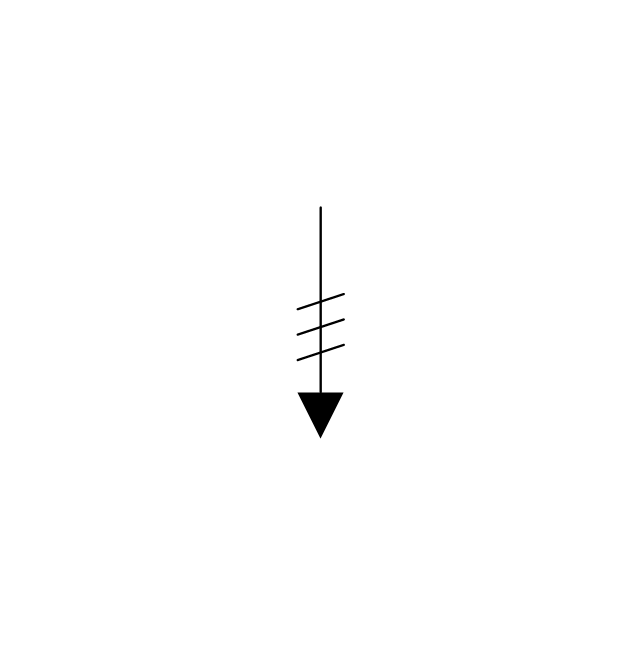

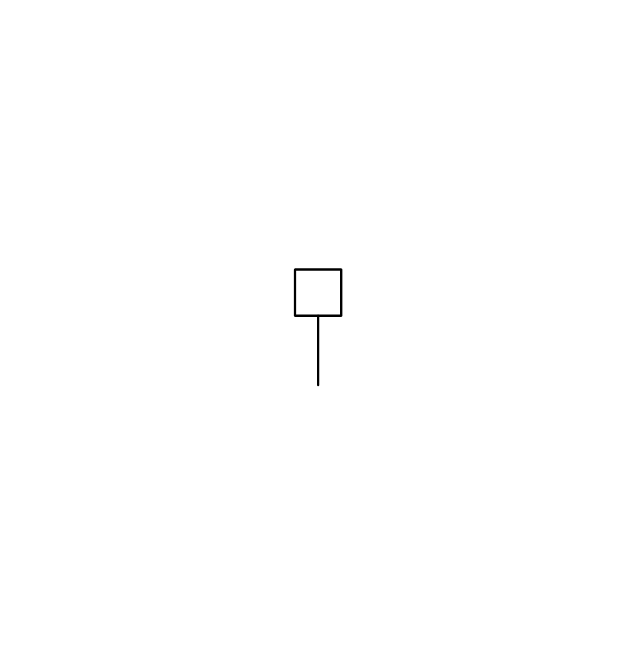

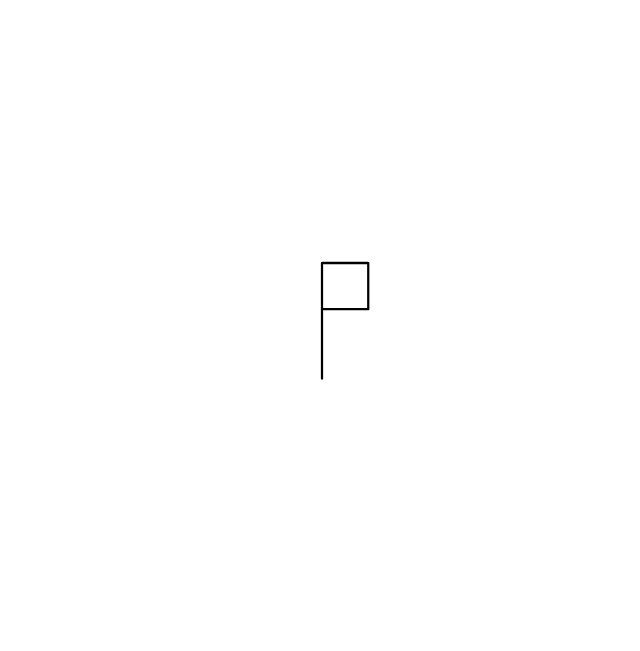

The vector stencils library "Valves" contains 91 symbols of valves. Use it for drawing plumbing and piping plans, schematic diagrams and blueprints of industrial piping systems; process, vacuum, and fluids piping; hydraulics piping; air and gas piping; materials distribution; and liquid transfer systems in the ConceptDraw PRO diagramming and vector drawing software extended with the Plumbing and Piping Plans solution from the Building Plans area of ConceptDraw Solution Park.

HelpDesk

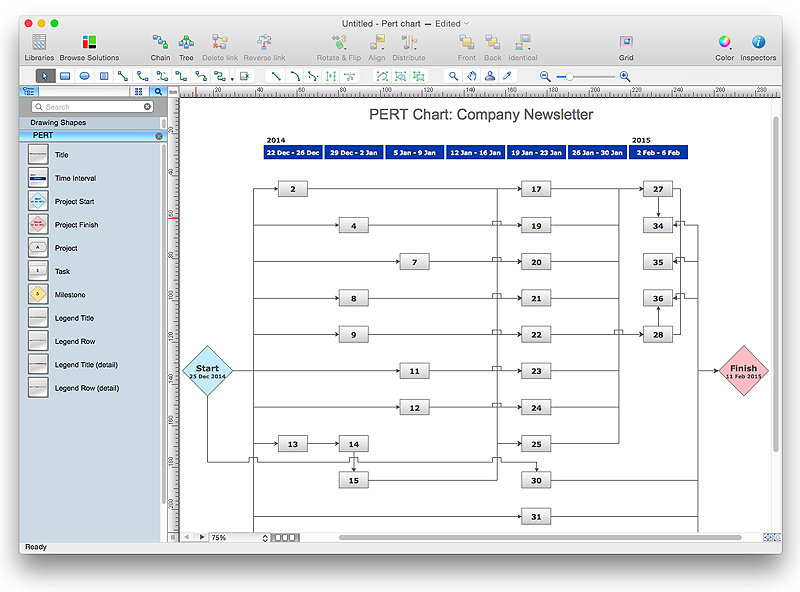

How To Create a PERT Chart

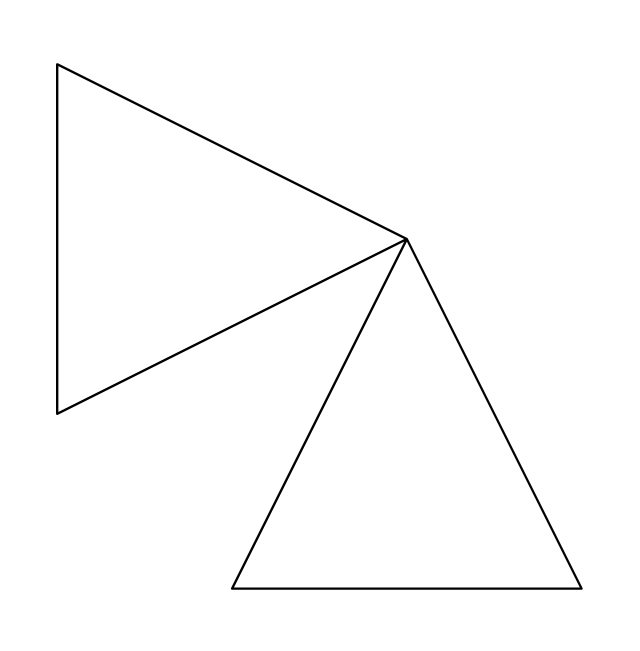

Project Evaluation and Review Technique (PERT) is a method of project tasks evaluation and analysis. PERT - is a method of analyzing the tasks required to complete the project. It includes analysis of the time required to complete each task, as well as the determination of the time required to carry out the whole project. PERT was developed to facilitate the planning of huge and complex projects. PERT is used for very large, complex, and non-standard projects. Technology implies the presence of uncertainty, making it possible to develop a schedule of the project without a precise information on details and time required for all of its components. The most popular part of PERT is a method of the critical path, based on the construction of the network schedule (PERT network diagram). ConceptDraw Office delivers you the best way to create PERT chart for your project using compatibility between ConceptDraw PROJECT and ConceptDraw PRO.- Valves - Vector stencils library | Directional control valve | Design ...

- Design elements - Alarm and access control | Bar Graphs | Activity ...

- Structured Systems Analysis and Design Method (SSADM) with ...

- Mechanical Drawing Symbols | Pneumatic 5-ported 3-position valve ...

- Probability Quality Control Tools | SWOT Analysis Solution - Strategy ...

- Hydraulic 4-ported 3-position valve template - Win | Valves - Vector ...

- Mechanical Drawing Symbols | Piping and Instrumentation Diagram ...

- Control Valve Symbol

- Mechanical Drawing Symbols | Pneumatic 5-ported 3-position valve ...

- Valves - Vector stencils library | Valve Scematic Stencils

- Context Diagram Template | Probability Quality Control Tools | ERD ...

- Mechanical Drawing Symbols | Pneumatic 5-ported 3-position valve ...

- Control Valve Assembly In Piping Drawing

- Structured Systems Analysis and Design Method (SSADM) with ...

- Design elements - Valves | Interior Design Piping Plan - Design ...

- TQM Diagram Tool | Probability Quality Control Tools | Quality ...

- Total Quality Management TQM Diagrams | Probability Quality ...

- Design elements - Valves | Piping and Instrumentation Diagram ...

- Structure Of Production Method