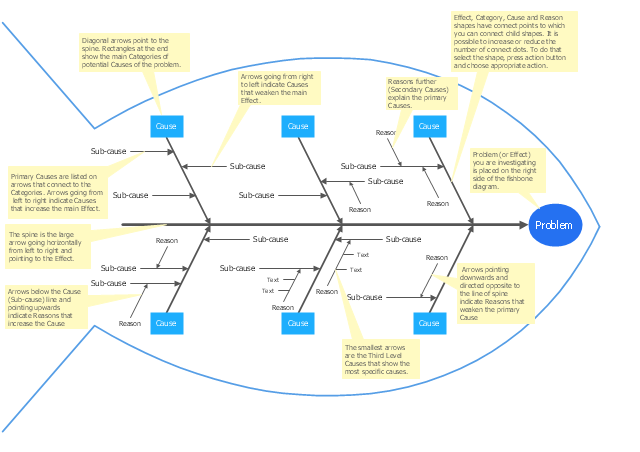

"Cause-and-effect diagrams can reveal key relationships among various variables, and the possible causes provide additional insight into process behavior.

Causes can be derived from brainstorming sessions. These groups can then be labeled as categories of the fishbone. They will typically be one of the traditional categories mentioned above but may be something unique to the application in a specific case. Causes can be traced back to root causes with the 5 Whys technique." [Ishikawa diagram. Wikipedia]

"The 5 Whys is an iterative question-asking technique used to explore the cause-and-effect relationships underlying a particular problem. The primary goal of the technique is to determine the root cause of a defect or problem. (The "5" in the name derives from an empirical observation on the number of iterations typically required to resolve the problem.)" [5 Whys. Wikipedia]

This Ishikawa diagram (cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

Causes can be derived from brainstorming sessions. These groups can then be labeled as categories of the fishbone. They will typically be one of the traditional categories mentioned above but may be something unique to the application in a specific case. Causes can be traced back to root causes with the 5 Whys technique." [Ishikawa diagram. Wikipedia]

"The 5 Whys is an iterative question-asking technique used to explore the cause-and-effect relationships underlying a particular problem. The primary goal of the technique is to determine the root cause of a defect or problem. (The "5" in the name derives from an empirical observation on the number of iterations typically required to resolve the problem.)" [5 Whys. Wikipedia]

This Ishikawa diagram (cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

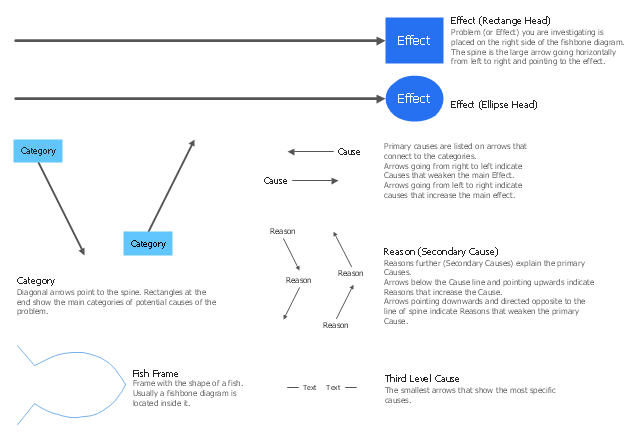

The library of vector stencils "Fishbone diagrams" contains 13 symbols for drawing the Ishikawa diagrams using the ConceptDraw PRO diagramming and vector drawing software.

"Ishikawa diagrams were popularized by Kaoru Ishikawa in the 1960s, who pioneered quality management processes in the Kawasaki shipyards, and in the process became one of the founding fathers of modern management.

The basic concept was first used in the 1920s, and is considered one of the seven basic tools of quality control. It is known as a fishbone diagram because of its shape, similar to the side view of a fish skeleton." [Ishikawa diagram. Wikipedia]

"The Seven Basic Tools of Quality is a designation given to a fixed set of graphical techniques identified as being most helpful in troubleshooting issues related to quality. They are called basic because they are suitable for people with little formal training in statistics and because they can be used to solve the vast majority of quality-related issues.

The seven tools are:

(1) Cause-and-effect diagram (also known as the "fishbone" or Ishikawa diagram);

(2) Check sheet;

(3) Control chart;

(4) Histogram;

(5) Pareto chart;

(6) Scatter diagram;

(7) Stratification (alternately, flow chart or run chart)." [Seven Basic Tools of Quality. Wikipedia]

The example "Design elements - Fishbone diagram" is included in the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park.

"Ishikawa diagrams were popularized by Kaoru Ishikawa in the 1960s, who pioneered quality management processes in the Kawasaki shipyards, and in the process became one of the founding fathers of modern management.

The basic concept was first used in the 1920s, and is considered one of the seven basic tools of quality control. It is known as a fishbone diagram because of its shape, similar to the side view of a fish skeleton." [Ishikawa diagram. Wikipedia]

"The Seven Basic Tools of Quality is a designation given to a fixed set of graphical techniques identified as being most helpful in troubleshooting issues related to quality. They are called basic because they are suitable for people with little formal training in statistics and because they can be used to solve the vast majority of quality-related issues.

The seven tools are:

(1) Cause-and-effect diagram (also known as the "fishbone" or Ishikawa diagram);

(2) Check sheet;

(3) Control chart;

(4) Histogram;

(5) Pareto chart;

(6) Scatter diagram;

(7) Stratification (alternately, flow chart or run chart)." [Seven Basic Tools of Quality. Wikipedia]

The example "Design elements - Fishbone diagram" is included in the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park.

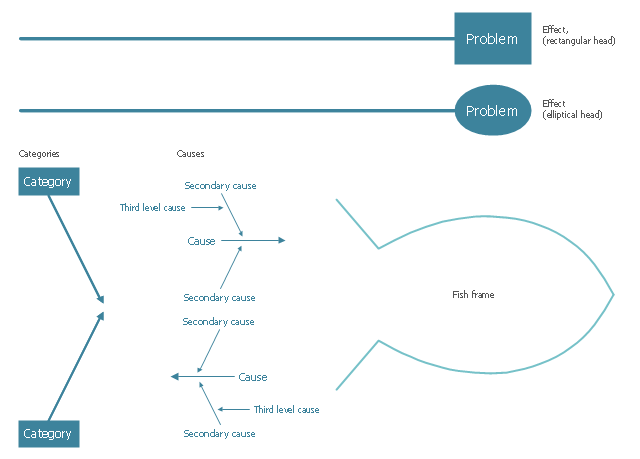

The vector stencils library "Cause-and-effect diagram" contains 13 elements of fishbone diagram.

Use it to design your Ishikawa diagrams with ConceptDraw PRO diagramming and vector drawing software.

"Ishikawa diagrams (also called fishbone diagrams, herringbone diagrams, cause-and-effect diagrams, or Fishikawa) are causal diagrams created by Kaoru Ishikawa (1968) that show the causes of a specific event. Common uses of the Ishikawa diagram are product design and quality defect prevention to identify potential factors causing an overall effect. Each cause or reason for imperfection is a source of variation. Causes are usually grouped into major categories to identify these sources of variation. ...

The basic concept was first used in the 1920s, and is considered one of the seven basic tools of quality control." [Ishikawa diagram. Wikipedia]

The example of fishbone diagram shapes "Design elements - Cause-and-effect diagram" is included in the Seven Basic Tools of Quality solution from the Quality area of ConceptDraw Solution Park.

Use it to design your Ishikawa diagrams with ConceptDraw PRO diagramming and vector drawing software.

"Ishikawa diagrams (also called fishbone diagrams, herringbone diagrams, cause-and-effect diagrams, or Fishikawa) are causal diagrams created by Kaoru Ishikawa (1968) that show the causes of a specific event. Common uses of the Ishikawa diagram are product design and quality defect prevention to identify potential factors causing an overall effect. Each cause or reason for imperfection is a source of variation. Causes are usually grouped into major categories to identify these sources of variation. ...

The basic concept was first used in the 1920s, and is considered one of the seven basic tools of quality control." [Ishikawa diagram. Wikipedia]

The example of fishbone diagram shapes "Design elements - Cause-and-effect diagram" is included in the Seven Basic Tools of Quality solution from the Quality area of ConceptDraw Solution Park.

- Design elements - Fishbone diagram | Fishbone diagram - Causes ...

- Fishbone Diagram | Cause and Effect Analysis (Fishbone Diagrams ...

- Fishbone diagram - Template | Manufacturing 8 Ms fishbone ...

- Design elements - Fishbone diagram | Probability Quality Control ...

- Cause & Effect Analysis | Fishbone Diagram Software for Design ...

- Fishbone diagram - Template | Ishikawa diagram - Factors reducing ...

- Design elements - Cause -and-effect diagram

- Well Labeled Diagram Of The Levels Of Management

- Fishbone Diagram | Cause and Effect Analysis (Fishbone Diagrams ...

- Fishbone Diagram | Business Productivity Diagramming | Cause ...

- Total Quality Management Value | TQM Diagram Tool | Design ...

- Fishbone Diagram | Seven Basic Tools of Quality - Fishbone ...

- Fishbone Diagram | Business Productivity Diagramming ...

- Fishbone Diagram | Design elements - Fishbone diagram | Audio ...

- Fishbone Diagram | Design elements - Fishbone diagram ...

- Total Quality Management Value | Business Productivity ...

- Fishbone Diagram | Quality fishbone diagram template | Fishbone ...

- Fishbone diagram - Causes of low-quality output | Design elements ...

- PROBLEM ANALYSIS. Root Cause Analysis Tree Diagram | Root ...

- Manufacturing 8 Ms fishbone diagram - Template | Ishikawa ...