"Causes in the diagram are often categorized, such as to the 6 M's ...

The 6 Ms (used in manufacturing industry)

- Machine (technology)

- Method (process)

- Material (Includes Raw Material, Consumables and Information.)

- Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions

- Measurement (Inspection)

- Milieu/ Mother Nature (Environment)

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

- Management/ Money Power

- Maintenance" [Ishikawa diagram. Wikipedia]

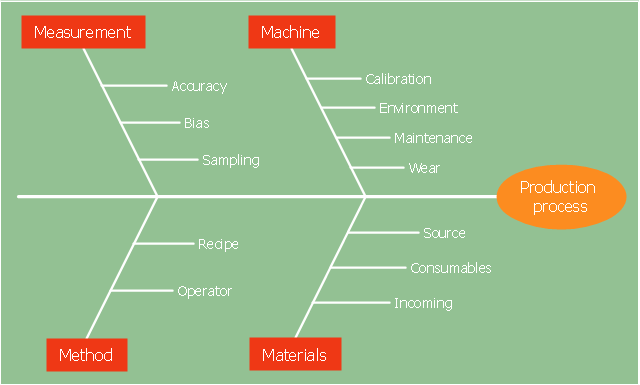

The 4Ms fishbone diagram (cause and effect diagram, Ishikawa diagram) example "Production process" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park.

The 6 Ms (used in manufacturing industry)

- Machine (technology)

- Method (process)

- Material (Includes Raw Material, Consumables and Information.)

- Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions

- Measurement (Inspection)

- Milieu/ Mother Nature (Environment)

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

- Management/ Money Power

- Maintenance" [Ishikawa diagram. Wikipedia]

The 4Ms fishbone diagram (cause and effect diagram, Ishikawa diagram) example "Production process" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park.

"Causes in the diagram are often categorized, such as to the 6 M's ...

The 6 Ms (used in manufacturing industry):

(1) Machine (technology);

(2) Method (process);

(3) Material (Includes Raw Material, Consumables and Information.);

(4) Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions;

(5) Measurement (Inspection);

(6) Milieu/ Mother Nature (Environment).

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

(7) Management/ Money Power;

(8) Maintenance." [Ishikawa diagram. Wikipedia]

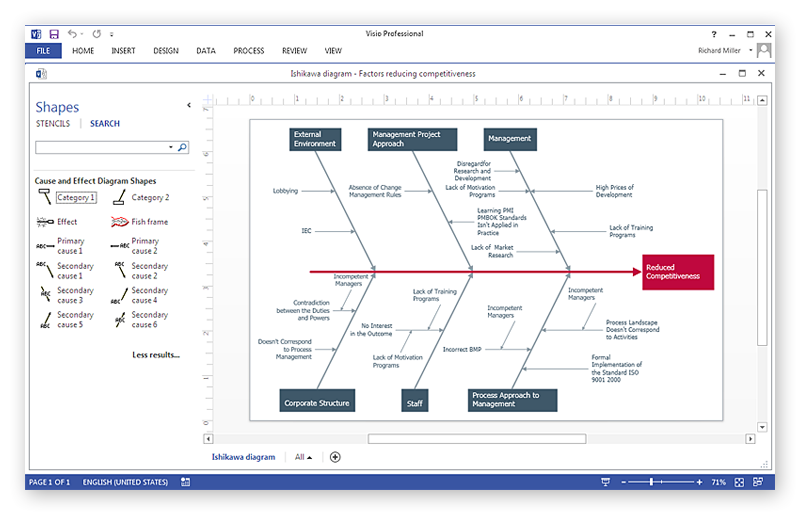

This 8Ms Ishikawa diagram (manufacturing cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

The 6 Ms (used in manufacturing industry):

(1) Machine (technology);

(2) Method (process);

(3) Material (Includes Raw Material, Consumables and Information.);

(4) Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions;

(5) Measurement (Inspection);

(6) Milieu/ Mother Nature (Environment).

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

(7) Management/ Money Power;

(8) Maintenance." [Ishikawa diagram. Wikipedia]

This 8Ms Ishikawa diagram (manufacturing cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

Fishbone Diagrams

Fishbone Diagrams

The Fishbone Diagrams solution extends ConceptDraw PRO v10 software with the ability to easily draw the Fishbone Diagrams (Ishikawa Diagrams) to clearly see the cause and effect analysis and also problem solving. The vector graphic diagrams produced using this solution can be used in whitepapers, presentations, datasheets, posters, and published technical material.

HelpDesk

How To Create a MS Visio Cause and Effect Diagram Using ConceptDraw PRO

Cause-and-Effect Ishikawa Diagram is a graphical method of analysis and cause-effect relationships, a tool in the form of fish bone. It is used to systematically determine the cause of the problem and represent it graphically. The technique is primarily used in the framework of quality management for the analysis of quality problems and their causes. Nowadays, it has found worldwide distribution and is used in multiple problem areas. It is one of the tools of lean manufacturing, which is used in group work to find the problems and their causes. ConceptDraw PRO allows you to easily create Fishbone (Ishikawa) diagram and then make a MS Visio VSDX, or VSD files from your diagrams in a couple clicks, using the export capabilities of ConcewptDraw PRO.HelpDesk

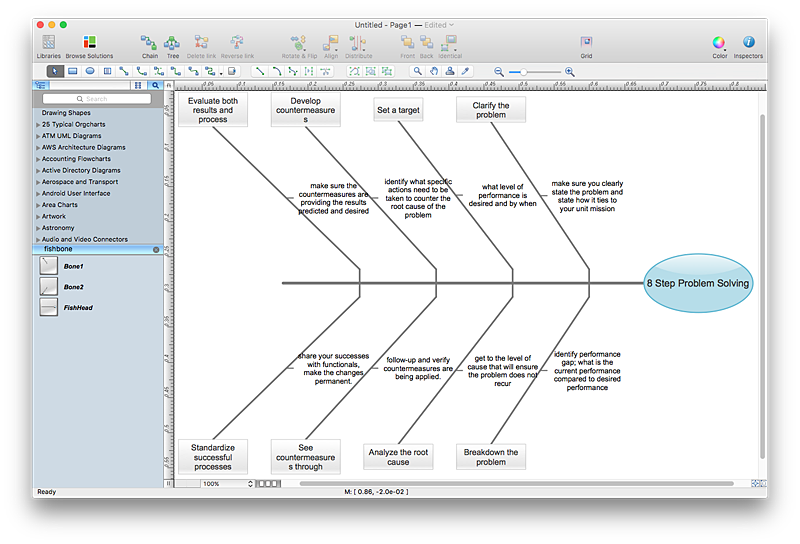

How to Create a Fishbone (Ishikawa) Diagram Quickly

A Fishbone (Ishikawa) diagram is also called cause-and-effect diagram. Fishbone diagram is often used in business to determine the cause of some problem. The diagram illustrates the main causes and sub-causes leading to an event. The main goal of the Fishbone diagram is to illustrate in a graphical way the relationship between a given outcome and all the factors that influence this outcome. The complete diagram resembles a fish skeleton as its name implies. The ability to create a Fishbone Diagram is supported by the Fishbone Diagram solution. Use ConceptDraw MINDMAP for structuring data and then ConceptDraw PRO for generating a Fishbone Diagram from mind map structure.HelpDesk

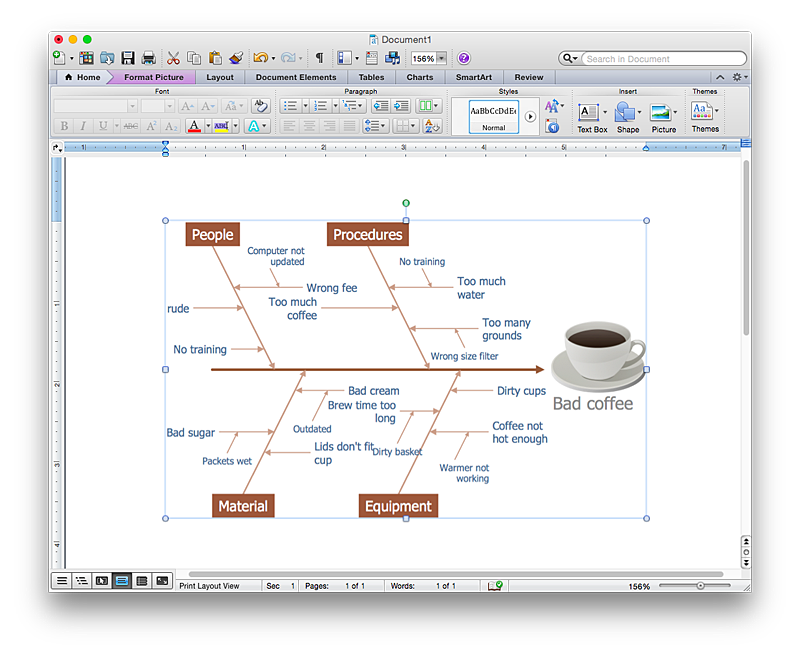

How to Add a Fishbone (Ishikawa) Diagram to a MS Word Document Using ConceptDraw PRO

The ability to create a fishbone (Ishikawa) Diagram is supported by the ConceptDraw Fishbone Diagram solution. ConceptDraw PRO allows you to easily create a fishbone diagrams and then insert them into a MS Word document.

Fishbone Diagram

Fishbone Diagram

Fishbone Diagrams solution extends ConceptDraw PRO software with templates, samples and library of vector stencils for drawing the Ishikawa diagrams for cause and effect analysis.

- Ishikawa Diagram Process

- 4 Ms fishbone diagram - Production process | Manufacturing 8 Ms ...

- Manufacturing 8 Ms fishbone diagram - Template | How Do ...

- 4 Ms fishbone diagram - Production process

- Process Flowchart | 4 Ms fishbone diagram - Production process ...

- Data Flow Diagram Model | Process Flowchart | How Do Fishbone ...

- Manufacturing 8 Ms fishbone diagram - Template

- Total Quality Management Value | Fishbone Diagram | 4ms Of ...

- Fishbone Diagram For Ms Word

- 4 Ms fishbone diagram - Production process | Defensive Formation ...

- Total Quality Management Value | Manufacturing 8 Ms fishbone ...

- Total Quality Management Value | Fishbone Diagram | What Is The ...

- Manufacturing 8 Ms fishbone diagram - Template | Fishbone ...

- Total Quality Management Value | Manufacturing 8 Ms fishbone ...

- Fishbone Diagram Example For Manufacturing Industry

- Manufacturing 8 Ms fishbone diagram - Template | Cause and Effect ...

- Ishikawa Diagram | Manufacturing 8 Ms fishbone diagram ...

- Manufacturing 8 Ms fishbone diagram - Template | How Do ...

- Manufacturing 8 Ms fishbone diagram - Template | Fishbone ...

- Manufacturing 8 Ms fishbone diagram - Template | How Do ...