Total Quality Management with ConceptDraw

Total Quality Management (TQM) system is the management method where the confidence in quality of all organization processes is placed foremost. The given method is widely used in production, in educational system, in government organizations and so on.How Do Fishbone Diagrams Solve Manufacturing Problems

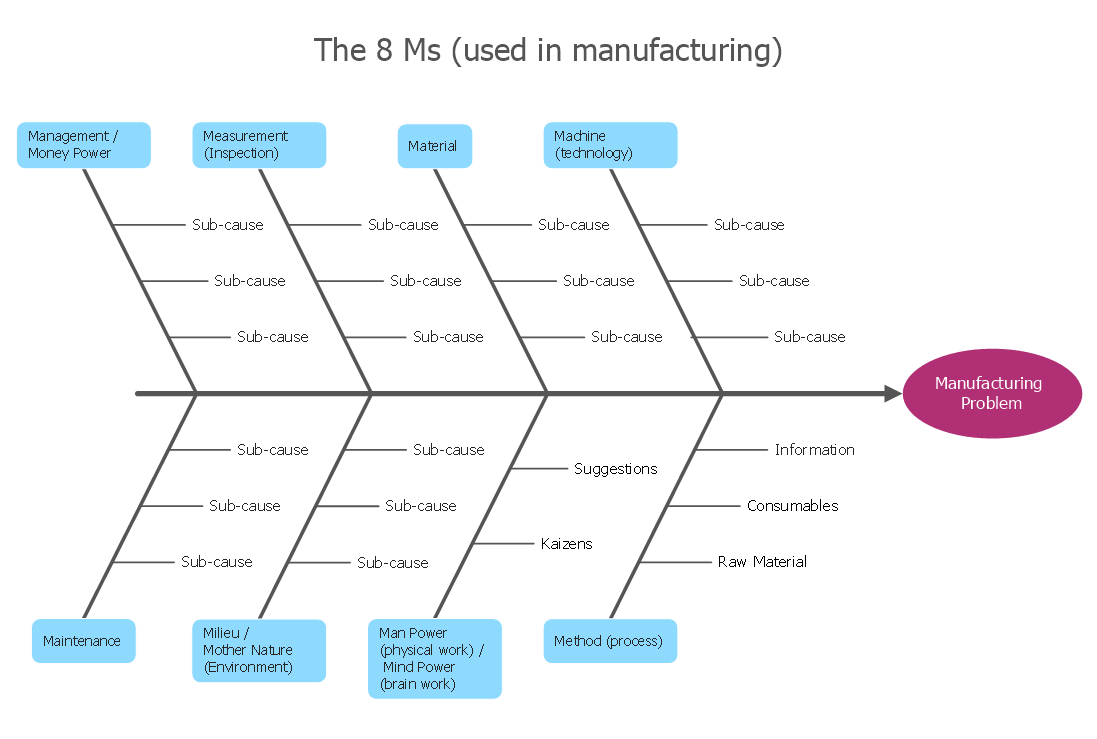

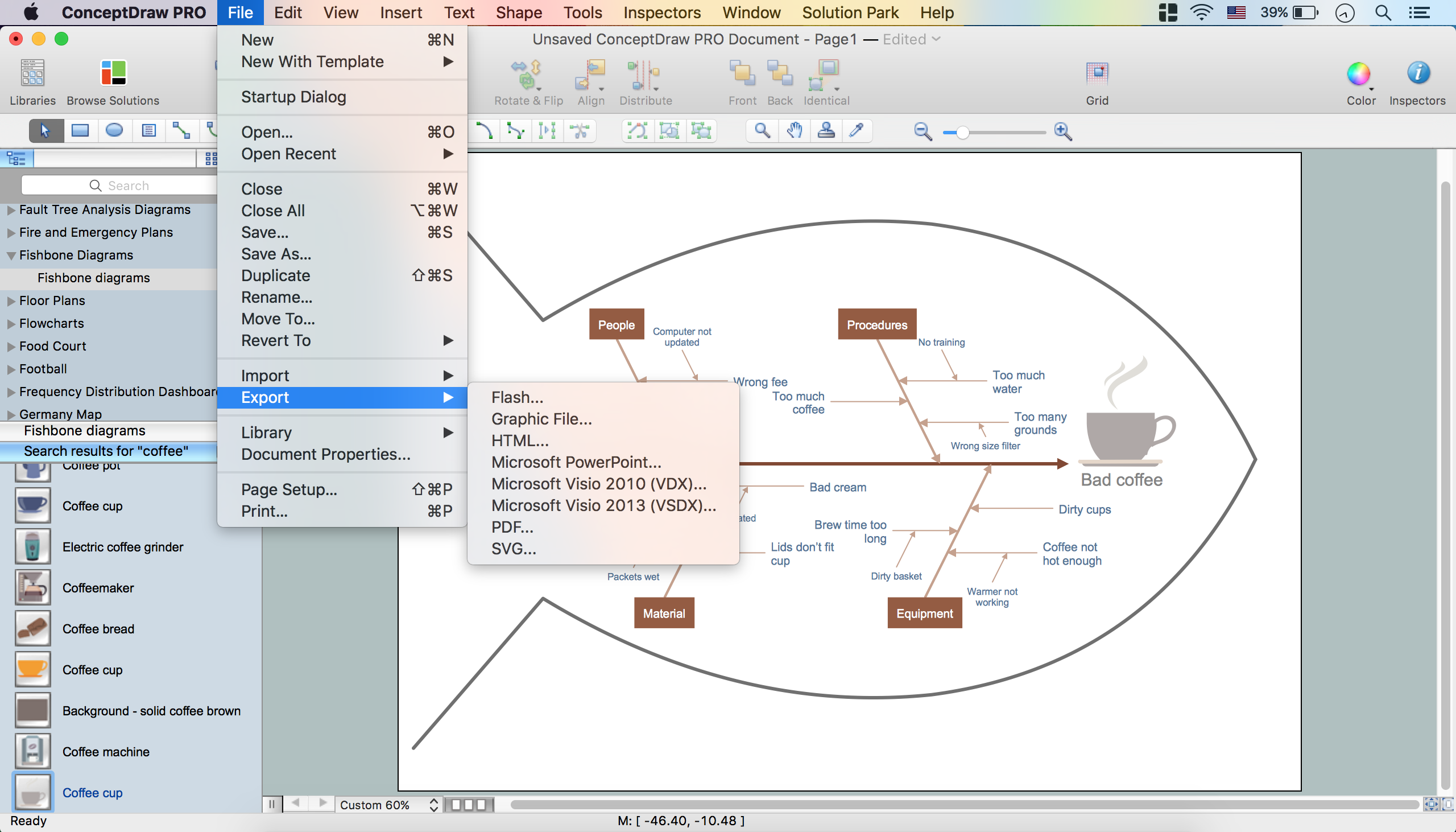

How do Fishbone diagrams solve manufacturing problems? Fishbone diagrams are successfully used in various fields of industries and manufacturing to analyze the set of possible causes and their effects. Fishbone diagram provides a process to clearly define the “Effect” and then puts you to thinking about the possible causes, based on the categories of common problems in manufacturing. ConceptDraw DIAGRAM application extended with Fishbone Diagrams solution lets you construct Fishbone diagrams and represent globally recognized standards for manufacturing 6 Ms and 8 Ms.Fishbone Diagram Procedure

ConceptDraw DIAGRAM diagramming and vector drawing software enhanced with Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park gives the ability to draw Fishbone diagram, which identifies many possible causes for an effect for problem solving. Fishbone Diagram procedure of creation includes the set of steps easy for execution in ConceptDraw DIAGRAM."Causes in the diagram are often categorized, such as to the 6 M's ...

The 6 Ms (used in manufacturing industry):

(1) Machine (technology);

(2) Method (process);

(3) Material (Includes Raw Material, Consumables and Information.);

(4) Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions;

(5) Measurement (Inspection);

(6) Milieu/ Mother Nature (Environment).

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

(7) Management/ Money Power;

(8) Maintenance." [Ishikawa diagram. Wikipedia]

This 8Ms Ishikawa diagram (manufacturing cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

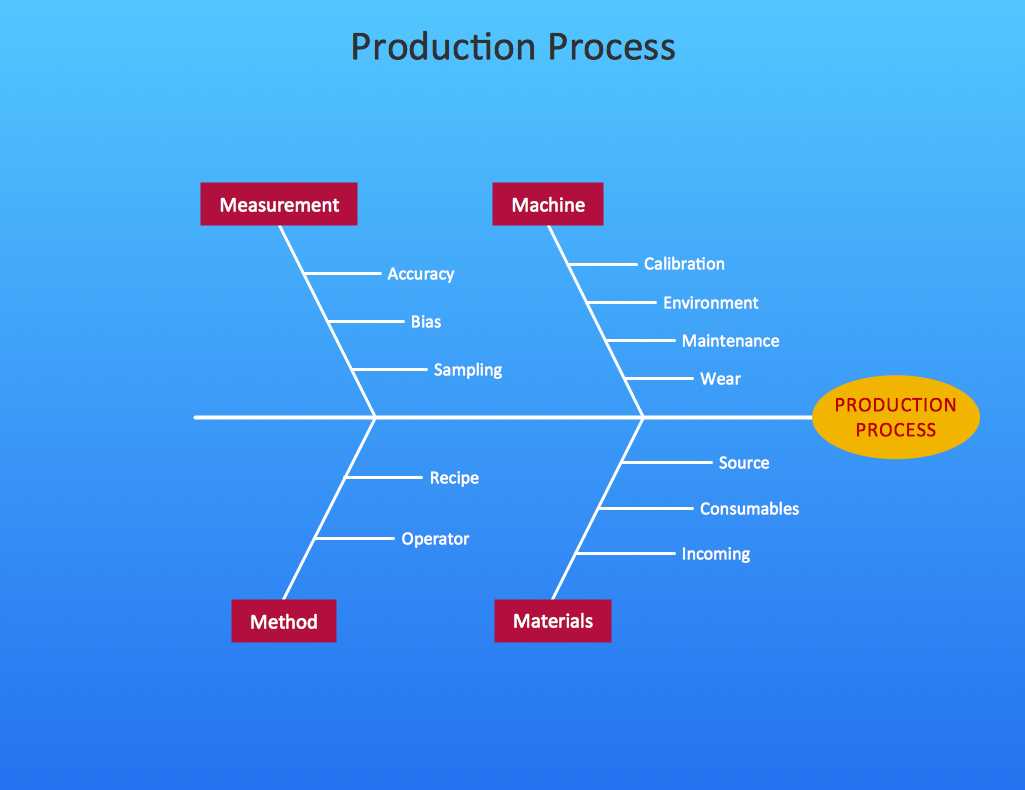

The 6 Ms (used in manufacturing industry):

(1) Machine (technology);

(2) Method (process);

(3) Material (Includes Raw Material, Consumables and Information.);

(4) Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions;

(5) Measurement (Inspection);

(6) Milieu/ Mother Nature (Environment).

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

(7) Management/ Money Power;

(8) Maintenance." [Ishikawa diagram. Wikipedia]

This 8Ms Ishikawa diagram (manufacturing cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

Cause and Effect Diagram

ConceptDraw DIAGRAM software extended with Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park is perfect for Cause and Effect Diagram creating. It gives the ability to draw fishbone diagram that identifies many possible causes for an effect or a problem. Causes and Effects are usually grouped into major categories to identify these sources of variation. Causes and Effects in the diagram show relationships among various factor. Fishbone diagram shows factors of Equipment, Process, People, Materials, Environment and Management, all affecting the overall problem.SWOT Analysis Tool for Small Business

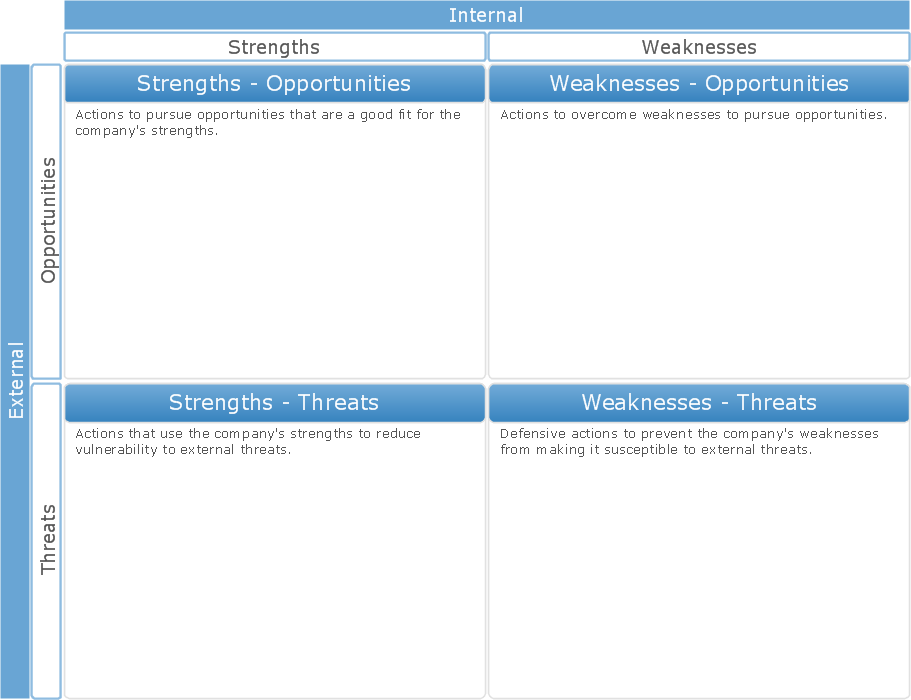

SWOT analysis is effective method of making the plan to evaluate the Strengths, Weaknesses, Opportunities, and Threats involved in a project. SWOT analysis includes the specifying project objectives and attentive identifying the internal and external causes for accomplishing the main project goals. It is actively used in large and small business project management for effective and clear identifying the critical factors. SWOT and TOWS Matrix Diagrams solution is included to ConceptDraw Solution Park and contains the high-quality analysis tools. This graphical solution turns the ConceptDraw DIAGRAM software in an excellent marketing management and advertising agency software, the best SWOT analysis tool for small business or large, as you like and need. Included graphic tools, visual and project planning components make it the best marketing project management software for marketing project planning and for making marketing presentations. Use the ConceptDraw DIAGRAM to create professional and well-designed SWOT matrices in minutes.Workflow Diagram

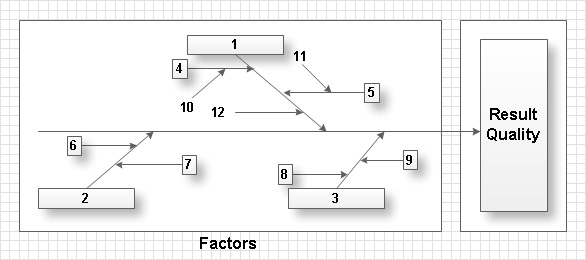

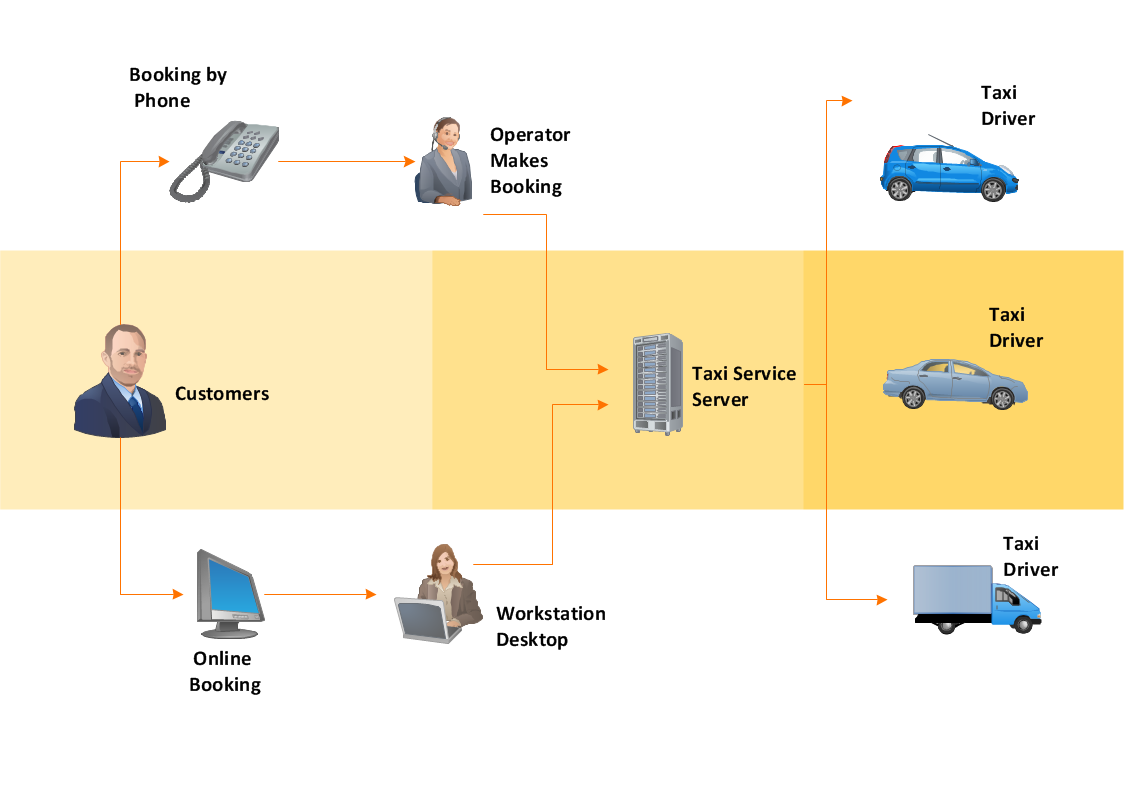

Workflow diagram is a perfect tool to represent visually a repeatable pattern of organizational activity that is powered by resources and to describe in details the transferring of data, documents or tasks during a work process. It effectively explains and documents the process flow that exists and that requires the studying, analyzing and execution. Workflow diagrams help to represent the working processes in a simple visual manner, to follow easy the path of a task in a workflow, to identify the persons responsible for the execution of each stage, to show the accompanied documents and needed resources. All this helps to optimize the workflow and to discover its weak points. Workflow diagrams are mainly designed and used as a part of project documentation, certification process and company policies to comply the standards. To design professionally the Workflow diagrams, use the ConceptDraw DIAGRAM software. Enhanced with Workflow Diagrams solution from the Business Processes area, the ConceptDraw DIAGRAM it is a powerful workflow diagram maker.How to Construct a Fishbone Diagram

Fishbone, Ishikawa or Cause and Effect diagram helps understand the reasons of completed or potential actions by structuring their causes in smaller categories. Also, one can use it to see how the contributing factors are related to each other. In everyday company routine, a Cause and Effect diagram is helpful with a number of regular activities like brainstorming, project management, and problem solving. How to Construct a Fishbone Diagram? Construction a Fishbone diagram in professional diagramming software ConceptDraw DIAGRAM is more easy than you think. Just use the predesigned vector elements from the Fishbone Diagrams library for Fishbone Diagrams solution or one of plenty Fishbone templates and examples, and you will get a Cause and Effect diagram in minutes.- 4m Method In Profuction Pdf

- Total Quality Management Value | Manufacturing 8 Ms fishbone ...

- 4m Problem Solving Methods Pdf

- Total Quality Management with ConceptDraw | 4m Analysis Method

- 4m Quality Method

- Total Quality Management Value | What Is 4m 1e In Quality

- 4m Change Training Ppt

- 4m Man Material Machine Method

- Man Machine Method Material Ppt

- Fishbone Diagrams for Problem Solving

- 4m Analysis Example

- 4 M Man Machine Method Material

- What Is 4m Variation

- Man Machine Material Method Pdf

- Manufacturing 8 Ms fishbone diagram - Template | Fishbone ...

- Manufacturing 8 Ms fishbone diagram - Template | Total Quality ...

- Cause and Effect Analysis - Fishbone Diagrams for Problem Solving ...

- 4m Change Flow Chart

- 4m In Total Quality Management

- Office Layout Plans | Cause and Effect Diagram | Www What Is 4m