"Waste minimization is the process and the policy of reducing the amount of waste produced by a person or a society.

Waste minimization involves efforts to minimize resource and energy use during manufacture. For the same commercial output, usually the fewer materials are used, the less waste is produced. Waste minimization usually requires knowledge of the production process, cradle-to-grave analysis (the tracking of materials from their extraction to their return to earth) and detailed knowledge of the composition of the waste. ...

In the waste hierarchy, the most effective approaches to managing waste are at the top. In contrast to waste minimisation, waste management focuses on processing waste after it is created, concentrating on re-use, recycling, and waste-to-energy conversion." [Waste minimisation. Wikipedia]

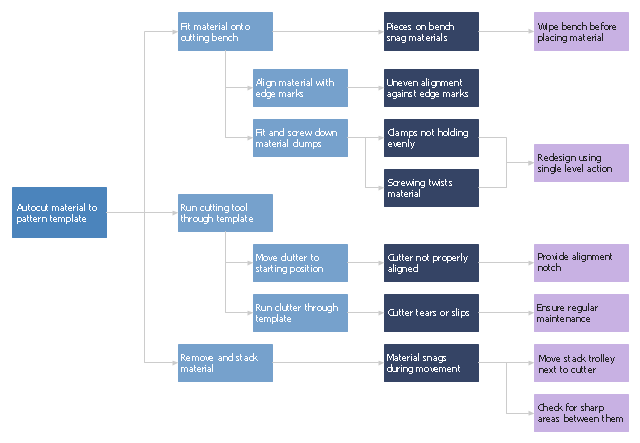

The process decision program chart (PDPC) example "Minimization of material wastage" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the solution "Seven Management and Planning Tools" from the Management area of ConceptDraw Solution Park.

Waste minimization involves efforts to minimize resource and energy use during manufacture. For the same commercial output, usually the fewer materials are used, the less waste is produced. Waste minimization usually requires knowledge of the production process, cradle-to-grave analysis (the tracking of materials from their extraction to their return to earth) and detailed knowledge of the composition of the waste. ...

In the waste hierarchy, the most effective approaches to managing waste are at the top. In contrast to waste minimisation, waste management focuses on processing waste after it is created, concentrating on re-use, recycling, and waste-to-energy conversion." [Waste minimisation. Wikipedia]

The process decision program chart (PDPC) example "Minimization of material wastage" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the solution "Seven Management and Planning Tools" from the Management area of ConceptDraw Solution Park.

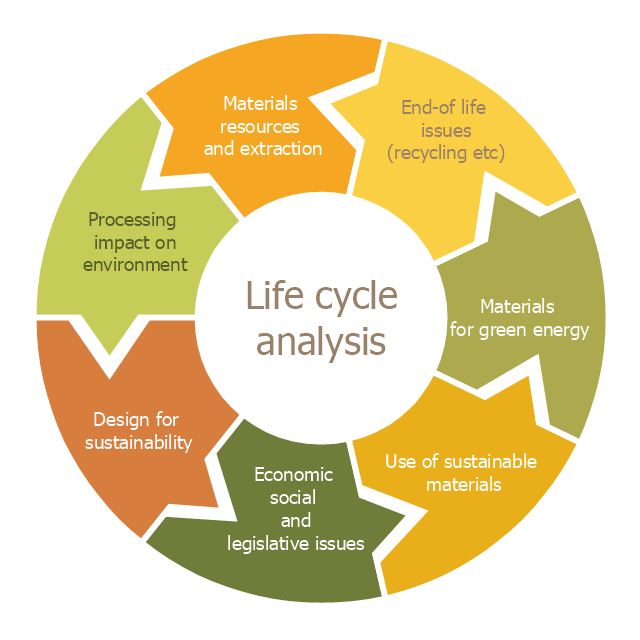

This cycle diagram sample was created on the base of the figure illustrating the article "Environmental Materials" by Cris Arnold from the website of the UK Centre for Materials Education of the Higher Education Academy. "The figure ... schematically shows how the disparate areas under the heading of 'environmental materials' can be linked via a life cycle analysis approach. ...

Life Cycle Analysis.

Life Cycle Analysis is essentially a method of considering the entire environmental impact, energy and resource usage of a material or product. It is often known as a 'cradle-to-grave' analysis and can encompass the entire lifetime from extraction to end-of-life disposal. Life cycle analysis can be an extremely effective way of linking many different aspects of the environmental impacts of materials usage. ...

Materials Extraction and Resource Implications.

The environmental impact of raw materials extraction and processing together with global resource issues provides a good place to start consideration of environmental aspects of materials. ...

Environmental Impacts of Processing.

... Topics that would come under this subject area include the specific environmental problems associated with processing of metals, polymers, ceramics, composites etc, and how these problems can be overcome.

Design for Sustainability.

This area ... will ... cover issues such as design for successful recycling, waste minimisation, energy efficiency and increased lifetime.

Economic, Social and Legislative Issues.

... For example, materials selection within the automotive industry is now heavily influenced by 'end-of-life vehicle' and 'hazardous material' regulations.

Use of Sustainable Materials.

... It is probably sensible to define such materials as those that have distinct differences that achieve environmental benefit compared to conventional materials. With this definition, the list would include:

(1) Materials of a significantly plant-based nature, including wood, natural fibre composites, natural polymers.

(2) Materials produced using a large proportion of waste material, including recycled polymers, composites made from waste mineral powders, and arguably also much steel and aluminium.

Materials for Green Energy.

The most exciting developments in Materials Science are in the realm of functional materials, and many of these serve an environmentally-beneficial purpose, particularly in the production of green energy.

These include:

(1) Solar-cell materials.

(2) Fuel-cell technology.

(3) Catalytic pollution control.

End-of-Life Issues.

The treatment of materials at the end of their lifetime is a significant subject area and encompasses aspects such as recycling techniques and materials limitations, biodegradabilty and composting, chemical recovery and energy recovery." [materials.ac.uk/ guides/ environmental.asp]

The ring chart example "Life cycle analysis" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Target and Circular Diagrams solution from the Marketing area of ConceptDraw Solution Park.

www.conceptdraw.com/ solution-park/ marketing-target-and-circular-diagrams

Life Cycle Analysis.

Life Cycle Analysis is essentially a method of considering the entire environmental impact, energy and resource usage of a material or product. It is often known as a 'cradle-to-grave' analysis and can encompass the entire lifetime from extraction to end-of-life disposal. Life cycle analysis can be an extremely effective way of linking many different aspects of the environmental impacts of materials usage. ...

Materials Extraction and Resource Implications.

The environmental impact of raw materials extraction and processing together with global resource issues provides a good place to start consideration of environmental aspects of materials. ...

Environmental Impacts of Processing.

... Topics that would come under this subject area include the specific environmental problems associated with processing of metals, polymers, ceramics, composites etc, and how these problems can be overcome.

Design for Sustainability.

This area ... will ... cover issues such as design for successful recycling, waste minimisation, energy efficiency and increased lifetime.

Economic, Social and Legislative Issues.

... For example, materials selection within the automotive industry is now heavily influenced by 'end-of-life vehicle' and 'hazardous material' regulations.

Use of Sustainable Materials.

... It is probably sensible to define such materials as those that have distinct differences that achieve environmental benefit compared to conventional materials. With this definition, the list would include:

(1) Materials of a significantly plant-based nature, including wood, natural fibre composites, natural polymers.

(2) Materials produced using a large proportion of waste material, including recycled polymers, composites made from waste mineral powders, and arguably also much steel and aluminium.

Materials for Green Energy.

The most exciting developments in Materials Science are in the realm of functional materials, and many of these serve an environmentally-beneficial purpose, particularly in the production of green energy.

These include:

(1) Solar-cell materials.

(2) Fuel-cell technology.

(3) Catalytic pollution control.

End-of-Life Issues.

The treatment of materials at the end of their lifetime is a significant subject area and encompasses aspects such as recycling techniques and materials limitations, biodegradabilty and composting, chemical recovery and energy recovery." [materials.ac.uk/ guides/ environmental.asp]

The ring chart example "Life cycle analysis" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Target and Circular Diagrams solution from the Marketing area of ConceptDraw Solution Park.

www.conceptdraw.com/ solution-park/ marketing-target-and-circular-diagrams

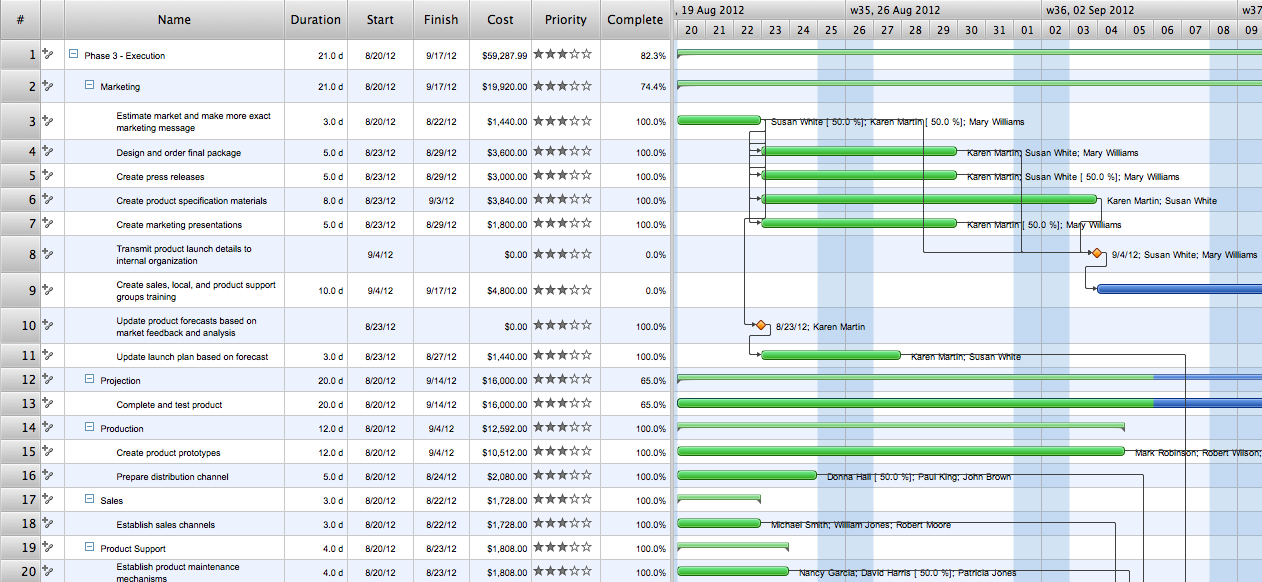

Project — Working With Costs

ConceptDraw PROJECT delivers a rich set of built-in functionalities and optional product extensions that support your daily workflow in time-saving and creative ways. This video lesson will teach you how to work with costs in your project document.HelpDesk

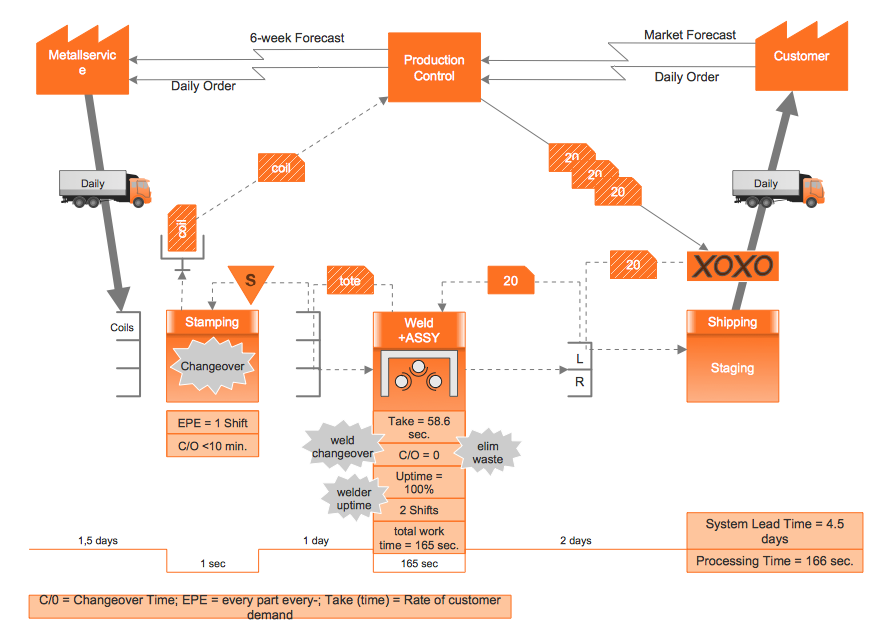

How to Create a VSM Diagram Using ConceptDraw Value Stream Mapping Solution

Value Stream Mapping is a Lean Manufacturing tool that uses a flow diagram to document in great detail every step of a manufacturing process. This graphical representation of a process is a powerful tool that helps in the diagnosis of process efficiency and allows companies to develop improved processes. Many lean practitioners use Value Stream Mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Many organizations use value stream mapping as a key portion of their lean efforts. Value Stream Maps are used to analyze and design the flow of materials and information required to bring a product or service to a consumer. You can create a Value Stream Mapping flowchart using ConceptDraw PRO tools.

Workflow Diagrams

Workflow Diagrams

Workflow Diagrams solution extends ConceptDraw PRO software with samples, templates and vector stencils library for drawing the work process flowcharts.

- Pie Chart Of Waste Material

- Draw Waste Materials Diagrams With Charts

- Make A Creative Flow Chart On Types Of Software Using Waste ...

- How To Make Water Cycle With Waste Material

- Draw Flowcharts with ConceptDraw | Steps of Accounting Cycle ...

- Material Requisition Flowchart. Flowchart Examples | Process ...

- Waste Material Diagram

- Waste Flow Chart

- Logistics Flow Charts | Pie Charts | Life cycle analysis - Ring chart ...

- Process decision program chart (PDPC) - Personal activity | Process ...

- Bar Diagrams for Problem Solving. Create economics and financial ...

- Pie Charts | Life cycle analysis - Ring chart | Basic Diagramming ...

- Flow chart Example. Warehouse Flowchart | Material Requisition ...

- Life cycle analysis - Ring chart | Flowchart Example: Flow Chart of ...

- Pie Charts | UK Map | Pie Graph Worksheets | Natural Resources ...

- Flowchart Example: Flow Chart of Marketing Analysis | Competitor ...

- Flow chart Example. Warehouse Flowchart | Material Requisition ...

- Risk Diagram (Process Decision Program Chart ) | Process decision ...

- Affinity Diagram | Types of Flowcharts | Life cycle analysis - Ring ...

- Process decision program chart (PDPC) - Personal activity ...