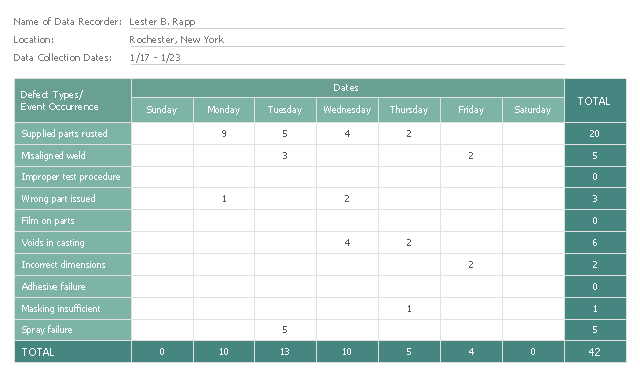

This check sheet example was redesigned from the Wikimedia Commons file: Check sheet for motor assembly.svg. [commons.wikimedia.org/ wiki/ File:Check_ sheet_ for_ motor_ assembly.svg]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"The check sheet is a form (document) used to collect data in real time at the location where the data is generated. The data it captures can be quantitative or qualitative. When the information is quantitative, the check sheet is sometimes called a tally sheet.

The check sheet is one of the so-called Seven Basic Tools of Quality Control. ...

Kaoru Ishikawa identified five uses for check sheets in quality control:

- To check the shape of the probability distribution of a process

- To quantify defects by type

- To quantify defects by location

- To quantify defects by cause (machine, worker)

- To keep track of the completion of steps in a multistep procedure (in other words, as a checklist)" [. Wikipedia]

The example "Check sheet for motor assembly" was created using the ConceptDraw PRO software extended with the Seven Basic Tools of Quality solution from the Quality area of ConceptDraw Solution Park.

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"The check sheet is a form (document) used to collect data in real time at the location where the data is generated. The data it captures can be quantitative or qualitative. When the information is quantitative, the check sheet is sometimes called a tally sheet.

The check sheet is one of the so-called Seven Basic Tools of Quality Control. ...

Kaoru Ishikawa identified five uses for check sheets in quality control:

- To check the shape of the probability distribution of a process

- To quantify defects by type

- To quantify defects by location

- To quantify defects by cause (machine, worker)

- To keep track of the completion of steps in a multistep procedure (in other words, as a checklist)" [. Wikipedia]

The example "Check sheet for motor assembly" was created using the ConceptDraw PRO software extended with the Seven Basic Tools of Quality solution from the Quality area of ConceptDraw Solution Park.

Used Solutions

Quality

>

Seven Basic Tools of Quality

Seven Basic Tools of Quality

Manage quality control in the workplace, using fishbone diagrams, flowcharts, Pareto charts and histograms, provided by the Seven Basic Tools of Quality solution.

- Check sheet for motor assembly | Seven Basic Tools of Quality ...

- Household Moving Checklist | Project management - Vector stencils ...

- Checklist Diagram Example

- Assembly Chart Example

- Assembly Of Machines

- Design elements - Hydraulic pumps and motors | Pneumatic pumps ...

- Probability Quality Control Tools | TQM Software — Build ...

- How to Use ConceptDraw Infographic in Presentations, Documents ...

- Probability Quality Control Tools | Definition TQM Diagram | Quality ...

- Basic Quality Check Tool

- Total Quality Management Value | Probability Quality Control Tools ...

- How To Make Histogram in ConceptDraw PRO? | Normal ...

- Foreign labor certification workflow | How to Connect Text Data to a ...

- Design elements - Hydraulic pumps and motors | Design elements ...

- Ishikawas Seven Basic Tools Of Quality

- Design elements - Title blocks | Design elements - Management title ...

- Motor Dayagram

- Manufacturing 8 Ms fishbone diagram - Template | Fishbone ...

- SWOT Matrix Template | UML Activity Diagram | Basic Workflow ...

- 5 Level pyramid model diagram - Information systems types ...