"Causes in the diagram are often categorized, such as to the 6 M's ...

The 6 Ms (used in manufacturing industry):

(1) Machine (technology);

(2) Method (process);

(3) Material (Includes Raw Material, Consumables and Information.);

(4) Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions;

(5) Measurement (Inspection);

(6) Milieu/ Mother Nature (Environment).

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

(7) Management/ Money Power;

(8) Maintenance." [Ishikawa diagram. Wikipedia]

This 8Ms Ishikawa diagram (manufacturing cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

The 6 Ms (used in manufacturing industry):

(1) Machine (technology);

(2) Method (process);

(3) Material (Includes Raw Material, Consumables and Information.);

(4) Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions;

(5) Measurement (Inspection);

(6) Milieu/ Mother Nature (Environment).

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

(7) Management/ Money Power;

(8) Maintenance." [Ishikawa diagram. Wikipedia]

This 8Ms Ishikawa diagram (manufacturing cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

"Causes in the diagram are often categorized, such as to the 6 M's ...

The 6 Ms (used in manufacturing industry)

- Machine (technology)

- Method (process)

- Material (Includes Raw Material, Consumables and Information.)

- Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions

- Measurement (Inspection)

- Milieu/ Mother Nature (Environment)

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

- Management/ Money Power

- Maintenance" [Ishikawa diagram. Wikipedia]

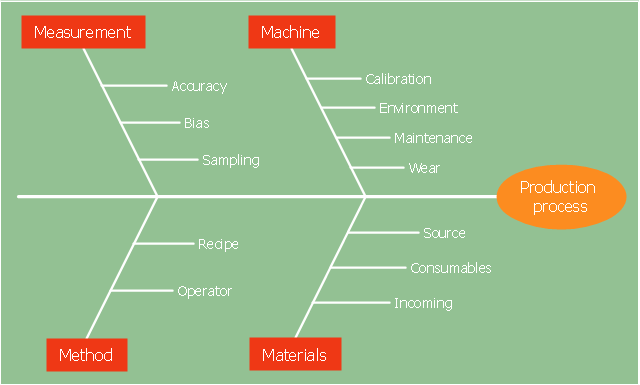

The 4Ms fishbone diagram (cause and effect diagram, Ishikawa diagram) example "Production process" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park.

The 6 Ms (used in manufacturing industry)

- Machine (technology)

- Method (process)

- Material (Includes Raw Material, Consumables and Information.)

- Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions

- Measurement (Inspection)

- Milieu/ Mother Nature (Environment)

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

- Management/ Money Power

- Maintenance" [Ishikawa diagram. Wikipedia]

The 4Ms fishbone diagram (cause and effect diagram, Ishikawa diagram) example "Production process" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park.

Total Quality Management Value

The Total quality management (TQM) is an enterprise-wide method of continuous quality improvement of all organizational processes, including the enhancement of ability to deliver high-quality products and services to the customers. The TQM includes eight main elements, which have great value: customer-focused, process-centered, total employee involvement, integrated system, continual improvement, strategic and systematic approach, fact-based decision making, communications. ConceptDraw PRO diagramming and vector drawing software offers the Total Quality Management Diagram solution with effective drawing tools, predesigned vector elements, samples and templates that help easy design the Total Quality Management diagrams, TQM flowcharts and Mind Maps widely used in quality management projects to visualize the business processes and industrial processes for your organization, to demonstrate the quality control step-by-step in a visual manner, to compare visually the ideal and real stages of processes.

Wireless Networks

Wireless Networks

The Wireless Networks Solution extends ConceptDraw PRO software with professional diagramming tools, set of wireless network diagram templates and samples, comprehensive library of wireless communications and WLAN objects to help network engineers and designers efficiently design and create Wireless network diagrams that illustrate wireless networks of any speed and complexity, and help to identify all required equipment for construction and updating wireless networks, and calculating their costs.

Aerospace and Transport

Aerospace and Transport

This solution extends ConceptDraw PRO software with templates, samples and library of vector clipart for drawing the Aerospace and Transport Illustrations. It contains clipart of aerospace objects and transportation vehicles, office buildings and anci

- Fishbone Diagram | Business Productivity Diagramming ...

- Fishbone Diagram | Fishbone diagram - Production process ...

- Fishbone Diagram | Business Productivity Diagramming | Business ...

- Fishbone Diagram | Service 8 Ps fishbone diagram template ...

- Fishbone Diagram | Fishbone diagram - Production process | Total ...

- Total Quality Management Value | Fishbone Diagram | Types of ...

- Fishbone Diagram | Event-driven Process Chain Diagrams EPC ...

- Fishbone Diagram | Business Productivity Diagramming | Cause ...

- Fishbone Diagram | Business Productivity Diagramming | Use a ...

- Fishbone diagram - Production process |

- Fishbone Diagram | Cause and Effect Analysis ( Fishbone Diagrams ...

- Total Quality Management with ConceptDraw | Management Tools ...

- Business Productivity Diagramming | Fishbone Diagram | Design ...

- Business Productivity Diagramming | Ishikawa diagram - Factors ...

- Business Productivity Diagramming | Business Productivity ...

- Business Productivity Diagramming | Total Quality Management with ...

- Fishbone Diagram | Fishbone diagram - Causes of low-quality ...

- Lean Manufacturing Diagrams | Root cause analysis tree diagram ...

- Total Quality Management Value

- Simple Flow Chart | Process Flowchart | How to Draw a Flowchart |