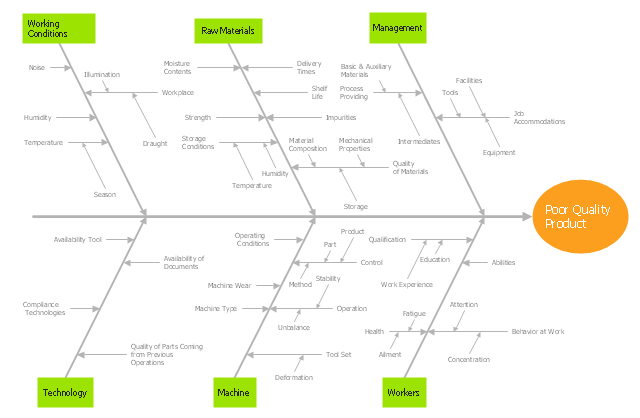

"Causes in the diagram are often categorized, such as to the 6 M's ...

The 6 Ms (used in manufacturing industry):

(1) Machine (technology);

(2) Method (process);

(3) Material (Includes Raw Material, Consumables and Information.);

(4) Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions;

(5) Measurement (Inspection);

(6) Milieu/ Mother Nature (Environment).

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

(7) Management/ Money Power;

(8) Maintenance." [Ishikawa diagram. Wikipedia]

This 8Ms Ishikawa diagram (manufacturing cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

The 6 Ms (used in manufacturing industry):

(1) Machine (technology);

(2) Method (process);

(3) Material (Includes Raw Material, Consumables and Information.);

(4) Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions;

(5) Measurement (Inspection);

(6) Milieu/ Mother Nature (Environment).

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

(7) Management/ Money Power;

(8) Maintenance." [Ishikawa diagram. Wikipedia]

This 8Ms Ishikawa diagram (manufacturing cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

Fishbone Diagrams

Fishbone Diagrams

The Fishbone Diagrams solution extends ConceptDraw PRO v10 software with the ability to easily draw the Fishbone Diagrams (Ishikawa Diagrams) to clearly see the cause and effect analysis and also problem solving. The vector graphic diagrams produced using this solution can be used in whitepapers, presentations, datasheets, posters, and published technical material.

"Ishikawa diagrams (also called fishbone diagrams, herringbone diagrams, cause-and-effect diagrams, or Fishikawa) are causal diagrams created by Kaoru Ishikawa (1968) that show the causes of a specific event. Common uses of the Ishikawa diagram are product design and quality defect prevention, to identify potential factors causing an overall effect. Each cause or reason for imperfection is a source of variation. Causes are usually grouped into major categories to identify these sources of variation. The categories typically include:

- People: Anyone involved with the process

- Methods: How the process is performed and the specific requirements for doing it, such as policies, procedures, rules, regulations and laws

- Machines: Any equipment, computers, tools, etc. required to accomplish the job

- Materials: Raw materials, parts, pens, paper, etc. used to produce the final product

- Measurements: Data generated from the process that are used to evaluate its quality

- Environment: The conditions, such as location, time, temperature, and culture in which the process operates" [Ishikawa diagram. Wikipedia]

The fishbone diagram example "Causes of low-quality output" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park.

- People: Anyone involved with the process

- Methods: How the process is performed and the specific requirements for doing it, such as policies, procedures, rules, regulations and laws

- Machines: Any equipment, computers, tools, etc. required to accomplish the job

- Materials: Raw materials, parts, pens, paper, etc. used to produce the final product

- Measurements: Data generated from the process that are used to evaluate its quality

- Environment: The conditions, such as location, time, temperature, and culture in which the process operates" [Ishikawa diagram. Wikipedia]

The fishbone diagram example "Causes of low-quality output" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park.

- Manufacturing 8 Ms fishbone diagram - Template | 8m Method ...

- Manufacturing 8 Ms fishbone diagram - Template | Fishbone ...

- Fishbone Diagrams | Manufacturing 8 Ms fishbone diagram ...

- Fish Bone Diagram For Man Machine Material And Method

- Process Flowchart | Fishbone Diagrams | Logistics Flow Charts ...

- Fishbone Diagrams | Process Flowchart | Logistics Flow Charts | E R ...

- Fishbone Diagram For Packaging Materials

- Manufacturing 8 Ms fishbone diagram - Template | How Do ...

- Fishbone Diagrams | Fish Bone Low Machine Performance Men ...