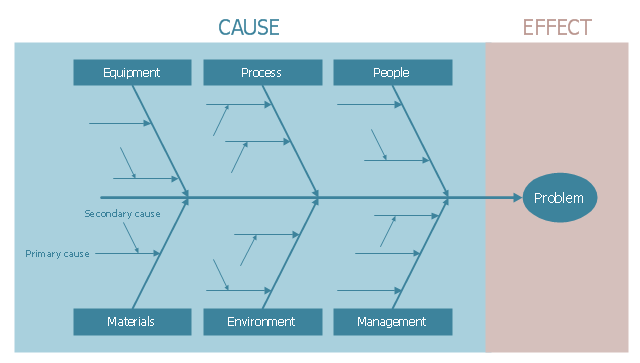

This cause-and-effect diagram example was redesigned from the Wikimedia Commons file: Ishikawa Fishbone Diagram.svg. [commons.wikimedia.org/ wiki/ File:Ishikawa_ Fishbone_ Diagram.svg]

"Ishikawa diagrams (also called fishbone diagrams, herringbone diagrams, cause-and-effect diagrams, or Fishikawa) are causal diagrams created by Kaoru Ishikawa (1968) that show the causes of a specific event. Common uses of the Ishikawa diagram are product design and quality defect prevention to identify potential factors causing an overall effect. Each cause or reason for imperfection is a source of variation. Causes are usually grouped into major categories to identify these sources of variation. The categories typically include

- People: Anyone involved with the process

- Methods: How the process is performed and the specific requirements for doing it, such as policies, procedures, rules, regulations and laws

- Machines: Any equipment, computers, tools, etc. required to accomplish the job

- Materials: Raw materials, parts, pens, paper, etc. used to produce the final product

- Measurements: Data generated from the process that are used to evaluate its quality

- Environment: The conditions, such as location, time, temperature, and culture in which the process operates" [Ishikawa diagram. Wikipedia]

The example "Ishikawa fishbone diagram" was created using the ConceptDraw PRO software extended with the Seven Basic Tools of Quality solution from the Quality area of ConceptDraw Solution Park.

"Ishikawa diagrams (also called fishbone diagrams, herringbone diagrams, cause-and-effect diagrams, or Fishikawa) are causal diagrams created by Kaoru Ishikawa (1968) that show the causes of a specific event. Common uses of the Ishikawa diagram are product design and quality defect prevention to identify potential factors causing an overall effect. Each cause or reason for imperfection is a source of variation. Causes are usually grouped into major categories to identify these sources of variation. The categories typically include

- People: Anyone involved with the process

- Methods: How the process is performed and the specific requirements for doing it, such as policies, procedures, rules, regulations and laws

- Machines: Any equipment, computers, tools, etc. required to accomplish the job

- Materials: Raw materials, parts, pens, paper, etc. used to produce the final product

- Measurements: Data generated from the process that are used to evaluate its quality

- Environment: The conditions, such as location, time, temperature, and culture in which the process operates" [Ishikawa diagram. Wikipedia]

The example "Ishikawa fishbone diagram" was created using the ConceptDraw PRO software extended with the Seven Basic Tools of Quality solution from the Quality area of ConceptDraw Solution Park.

- Ishikawa Template

- Ishikawa Diagram Examples Education

- Ishikawa Diagram | Fishbone Diagram Example | Ishikawa fishbone ...

- Ishikawa Diagram | Total Quality Management Value | Using ...

- How to Create a Fishbone ( Ishikawa ) Diagram Quickly | Process ...

- Examples Of Ishikawa Diagram In Manufacturing Companies

- Ishikawa Diagram | Flowcharts | Solved Problems On Swot Analysis ...

- Cause And Effect Analysis Example

- Fishbone Diagram Example | Ishikawa Diagram | Fishbone Diagram ...

- Ishikawa Diagram Examples Ppt

- Ishikawa Diagram For System Development

- Analysis Diagram Examples

- Ishikawa Diagram Simple Example

- Fishbone Diagram | Workflow Diagram Examples | Fishbone ...

- Fishbone Diagrams | Engineering | Process Flowchart | Ishikawa ...

- Fishbone Diagram Product Safety Example

- Fishbone diagram - Production process

- Examples Of Fishbone Map

- Fishbone Diagrams | Example of DFD for Online Store (Data Flow ...

- How to Create a Fishbone ( Ishikawa ) Diagram Quickly | When To ...