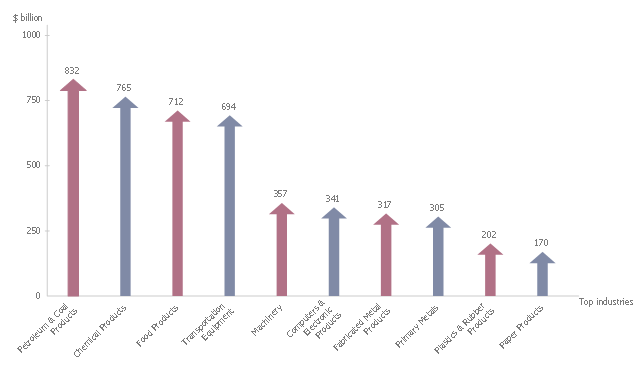

This arrows bar chart example shows the total value of manufacturers' shipments. It was drawn on the base of the infographics "Inside America's Economic Machine" from the website of the United States Census Bureau.

[census.gov/ how/ img/ Econ_ Infographic.jpg]

"The Advance Report on Durable Goods Manufacturer's Shipments, Inventories and Orders, or the Durable Goods Report, provides data on new orders received from more than 4,000 manufacturers of durable goods, which are generally defined as higher-priced capital goods orders with a useful life of three years or more, such as cars, semiconductor equipment and turbines.More than 85 industries are represented in the sample, which covers the entire United States." [Economic Indicators: Durable Goods Report. R. Barnes. investopedia.com/ university/ releases/ durablegoods.asp]

The arrow graph example "Total value of manufacturers' shipments" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Basic Picture Graphs solution from the Graphs and Charts area of ConceptDraw Solution Park.

[census.gov/ how/ img/ Econ_ Infographic.jpg]

"The Advance Report on Durable Goods Manufacturer's Shipments, Inventories and Orders, or the Durable Goods Report, provides data on new orders received from more than 4,000 manufacturers of durable goods, which are generally defined as higher-priced capital goods orders with a useful life of three years or more, such as cars, semiconductor equipment and turbines.More than 85 industries are represented in the sample, which covers the entire United States." [Economic Indicators: Durable Goods Report. R. Barnes. investopedia.com/ university/ releases/ durablegoods.asp]

The arrow graph example "Total value of manufacturers' shipments" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Basic Picture Graphs solution from the Graphs and Charts area of ConceptDraw Solution Park.

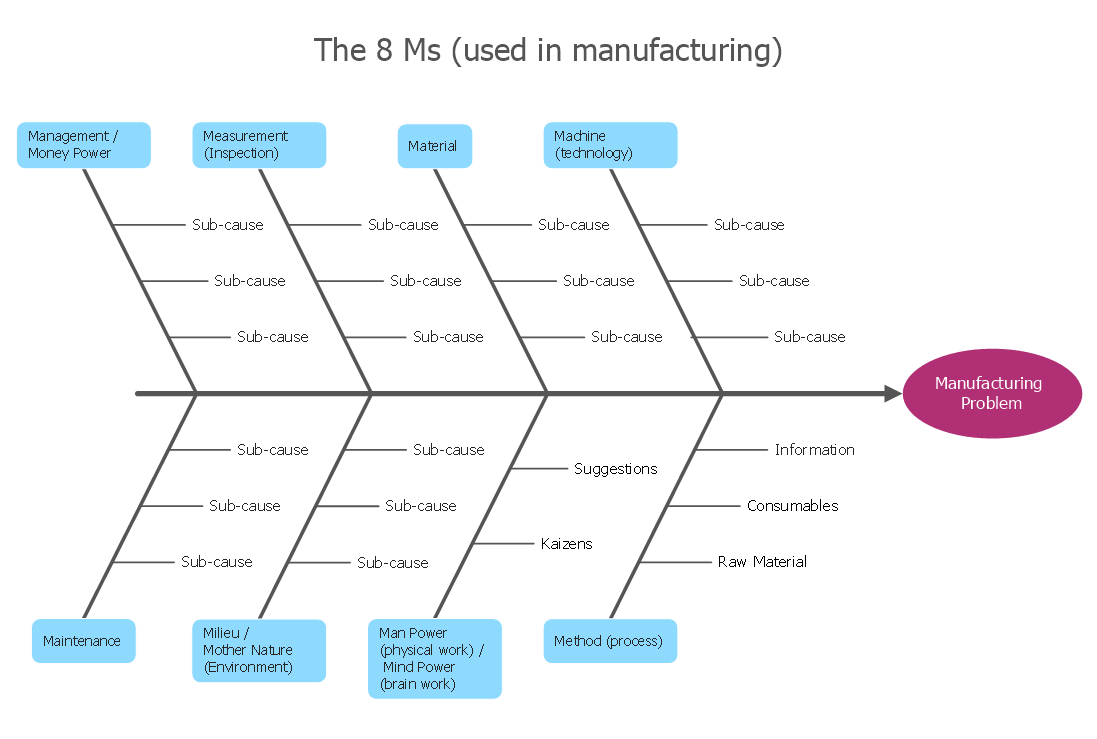

"Causes in the diagram are often categorized, such as to the 6 M's ...

The 6 Ms (used in manufacturing industry):

(1) Machine (technology);

(2) Method (process);

(3) Material (Includes Raw Material, Consumables and Information.);

(4) Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions;

(5) Measurement (Inspection);

(6) Milieu/ Mother Nature (Environment).

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

(7) Management/ Money Power;

(8) Maintenance." [Ishikawa diagram. Wikipedia]

This 8Ms Ishikawa diagram (manufacturing cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

The 6 Ms (used in manufacturing industry):

(1) Machine (technology);

(2) Method (process);

(3) Material (Includes Raw Material, Consumables and Information.);

(4) Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions;

(5) Measurement (Inspection);

(6) Milieu/ Mother Nature (Environment).

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

(7) Management/ Money Power;

(8) Maintenance." [Ishikawa diagram. Wikipedia]

This 8Ms Ishikawa diagram (manufacturing cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

How Do Fishbone Diagrams Solve Manufacturing Problems

How do Fishbone diagrams solve manufacturing problems? Fishbone diagrams are successfully used in various fields of industries and manufacturing to analyze the set of possible causes and their effects. Fishbone diagram provides a process to clearly define the “Effect” and then puts you to thinking about the possible causes, based on the categories of common problems in manufacturing. ConceptDraw DIAGRAM application extended with Fishbone Diagrams solution lets you construct Fishbone diagrams and represent globally recognized standards for manufacturing 6 Ms and 8 Ms.Value-Stream Mapping for Manufacturing

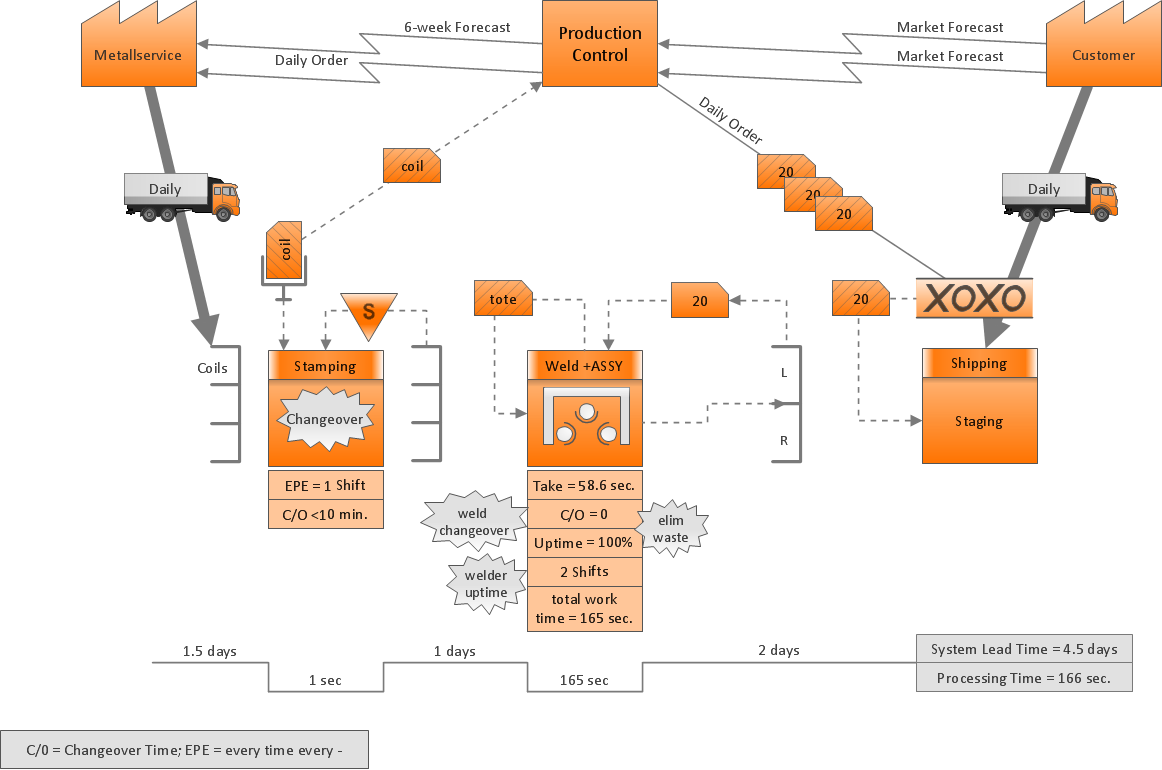

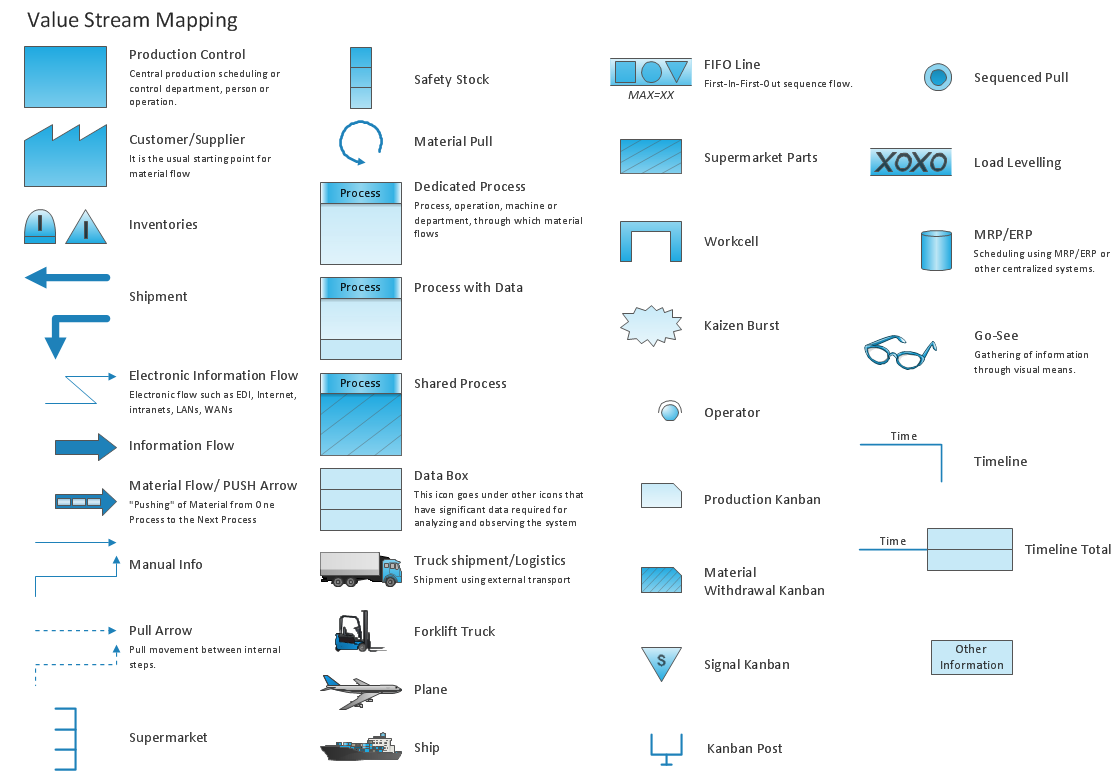

Create value stream maps - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.

Manufacturing and Maintenance

Manufacturing and Maintenance

Manufacturing and maintenance solution extends ConceptDraw DIAGRAM software with illustration samples, templates and vector stencils libraries with clip art of packaging systems, industrial vehicles, tools, resources and energy.

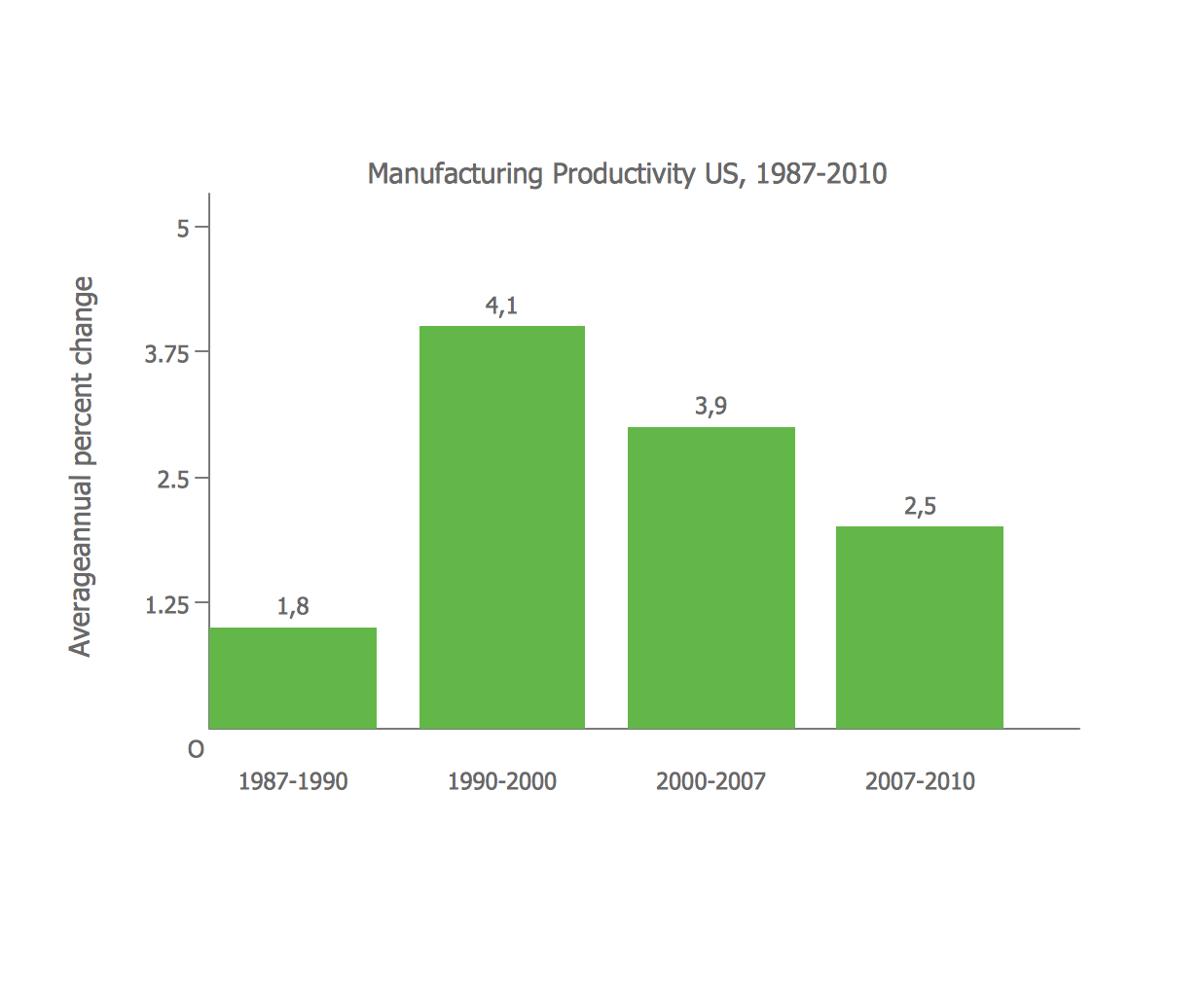

Bar Diagrams for Problem Solving. Create manufacturing and economics bar charts with Bar Graphs Solution

Create bar charts for visualizing problem solving in manufacturing and economics using the ConceptDraw DIAGRAM diagramming and vector drawing software extended with the Bar Graphs Solution from the Graphs and Charts area of ConceptDraw Solition Park.Lean Manufacturing Diagrams

The Value Stream Mapping solution continues to extend the range of ConceptDraw DIAGRAM into a business graphics tool that can be used to document processes of Lean Manufacturing.- Picture graph - Template | Manufacturing in America | Total value of ...

- Welding Symbol For Manufacturing Drawing

- Manufacturing Floor Plan Layout

- How Do Fishbone Diagrams Solve Manufacturing Problems ...

- Explain Services Of Wholesalers Services To Manufacturers

- Total value of manufacturers ' shipments | Widget price correlation ...

- Arrow graph - Total value of manufacturers ' shipments | Venn ...

- Manufacturing 8 Ms fishbone diagram - Template | Fishbone ...

- Cross Functional Flowchart Examples | Manufacturing Process Flow ...