Plan-Do-Check-Act (PDCA)

Plan-Do-Check-Act (PDCA)

Plan-Do-Check-Act (PDCA) solution extends the ConceptDraw PRO software with collection of samples and predesigned vector objects for easy visualization four stages of PDCA cycle, PDSA cycle, or Deming cycle, for illustration effective application of this method to the practical business tasks, for depiction the implementation of changes and solution the problems in business processes. Plan-Do-Check-Act (PDCA) solution helps to design professional-looking and attractive Plan Do Study Act diagrams, PDCA cycle diagrams, PDCA Process diagrams, and to construct the Quality Management Process Models, which all assist to manage efficiently the business processes, to improve quality of work and to reduce significantly the costs.

HelpDesk

How to Create PDCA Diagram

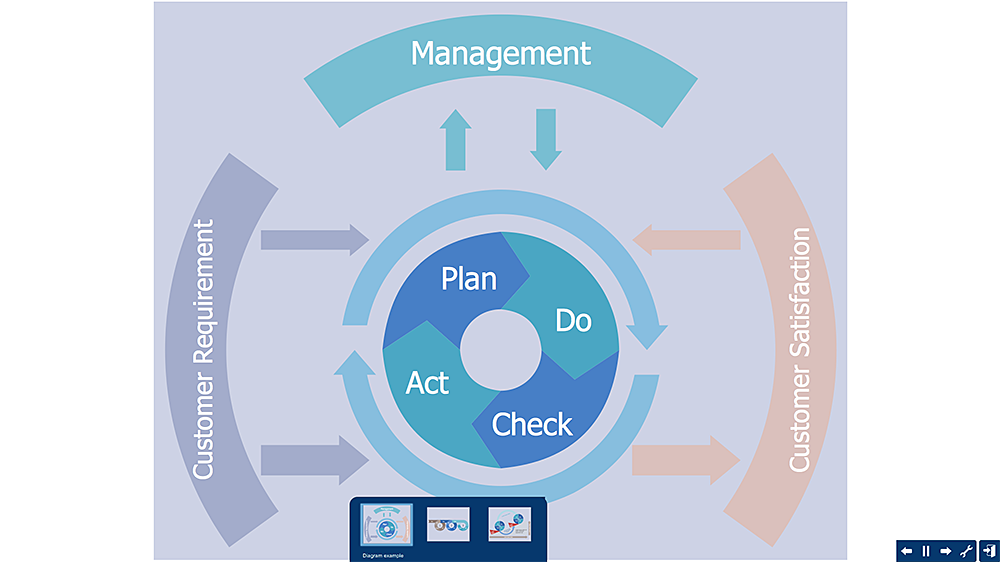

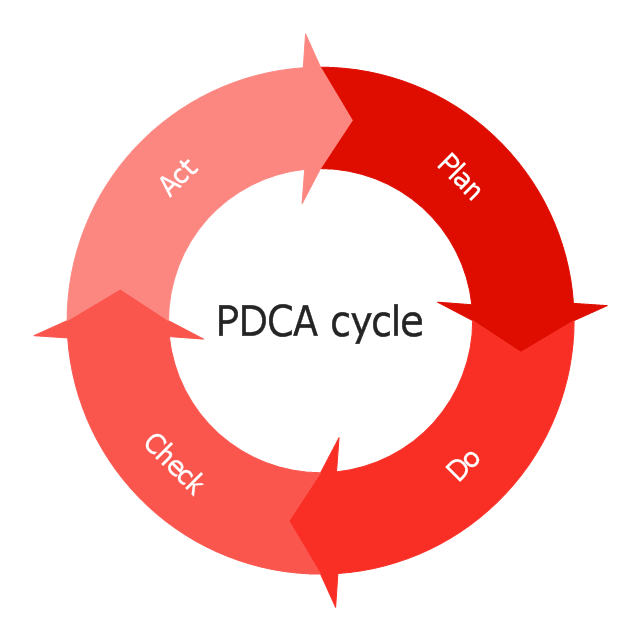

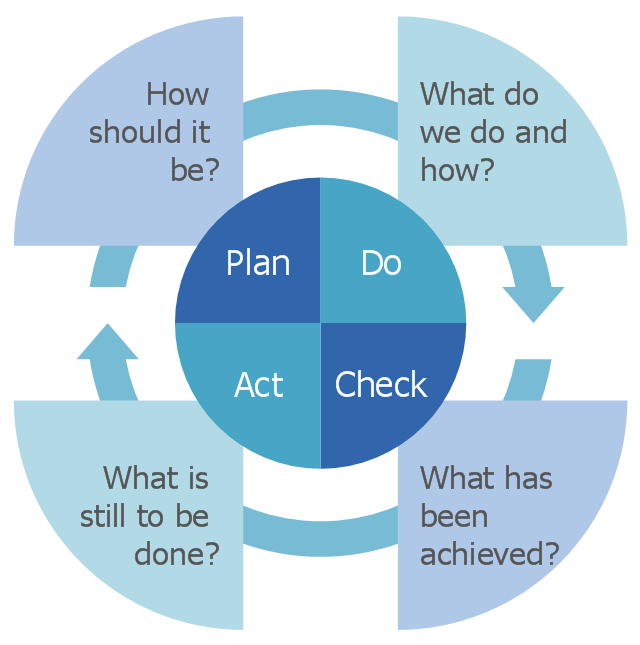

Plan-Do-Check-Act (PDCA) solution for ConceptDraw PRO helps to design Plan Do Study Act diagrams, PDCA cycle diagrams, PDCA Process diagrams, and to construct the Quality Management Process Models. It is used for easy visualization of PDCA cycle, PDSA cycle, or Deming cycle - the management methods of the business process continuous improvement.This circular arrows diagram sample depicts the Plan–Do–Check–Act cycle.

"PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continuous improvement of processes and products. It is also known as the Deming circle/ cycle/ wheel, Shewhart cycle, control circle/ cycle, or plan–do–study–act (PDSA). Another version of this PDCA cycle is OPDCA. The added "O" stands for observation or as some versions say "Grasp the current condition." This emphasis on observation and current condition has currency with Lean manufacturing/ Toyota Production System literature." [PDCA. Wikipedia]

The diagram example "PDCA cycle" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Circular Arrows Diagrams solution from the area "What is a Diagram" of ConceptDraw Solution Park.

"PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continuous improvement of processes and products. It is also known as the Deming circle/ cycle/ wheel, Shewhart cycle, control circle/ cycle, or plan–do–study–act (PDSA). Another version of this PDCA cycle is OPDCA. The added "O" stands for observation or as some versions say "Grasp the current condition." This emphasis on observation and current condition has currency with Lean manufacturing/ Toyota Production System literature." [PDCA. Wikipedia]

The diagram example "PDCA cycle" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Circular Arrows Diagrams solution from the area "What is a Diagram" of ConceptDraw Solution Park.

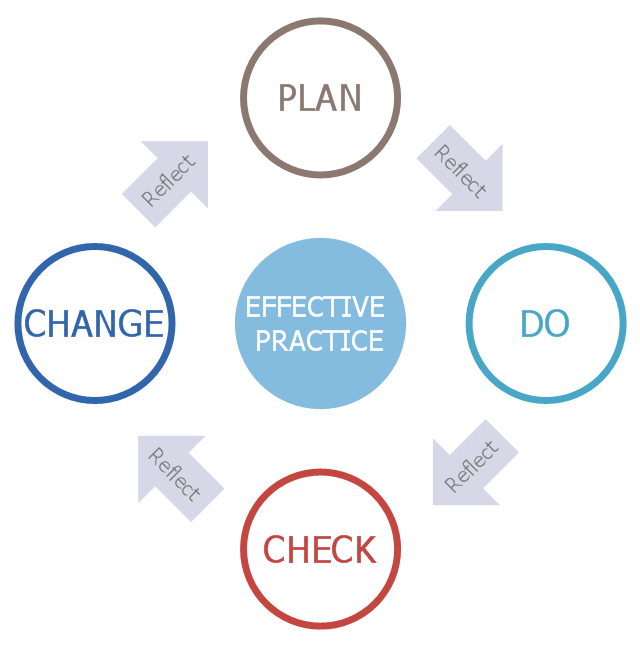

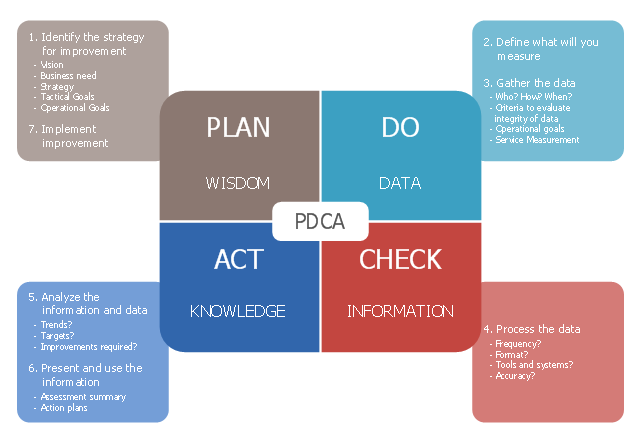

This Deming cycle sample shows plan-do-check-change diagram variance.

It was designed on the base of Wikimedia Commons file: Learning process and quality standards.png. [commons.wikimedia.org/ wiki/ File:Learning_ process_ and_ quality_ standards.png]

"Rate of change, that is, rate of improvement, is a key competitive factor in today's world. PDCA allows for major "jumps" in performance ("breakthroughs" often desired in a Western approach), as well as Kaizen (frequent small improvements). In the United States a PDCA approach is usually associated with a sizable project involving numerous people's time, and thus managers want to see large "breakthrough" improvements to justify the effort expended. However, the scientific method and PDCA apply to all sorts of projects and improvement activities." [PDCA. Wikipedia]

The plan-do-check-change diagram example "Effective practice PDCA" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

It was designed on the base of Wikimedia Commons file: Learning process and quality standards.png. [commons.wikimedia.org/ wiki/ File:Learning_ process_ and_ quality_ standards.png]

"Rate of change, that is, rate of improvement, is a key competitive factor in today's world. PDCA allows for major "jumps" in performance ("breakthroughs" often desired in a Western approach), as well as Kaizen (frequent small improvements). In the United States a PDCA approach is usually associated with a sizable project involving numerous people's time, and thus managers want to see large "breakthrough" improvements to justify the effort expended. However, the scientific method and PDCA apply to all sorts of projects and improvement activities." [PDCA. Wikipedia]

The plan-do-check-change diagram example "Effective practice PDCA" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

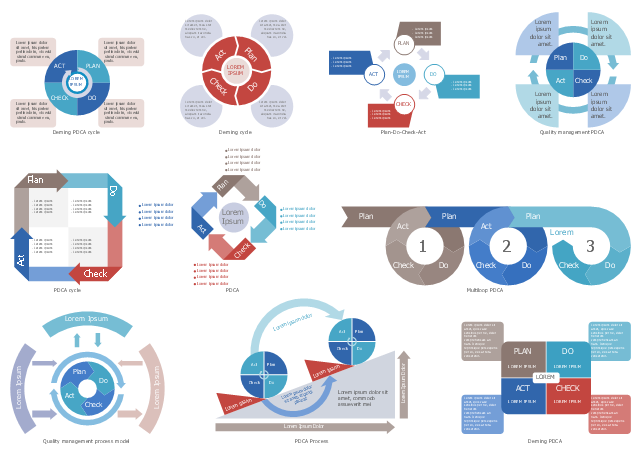

The vector stencils library PDCA contains 10 Plan-Do-Check-Act cycle diagram shapes.

Use it to design your Deming cycle diagrams with ConceptDraw PRO software.

"PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continual improvement of processes and products. It is also known as the Deming circle/ cycle/ wheel, Shewhart cycle, control circle/ cycle, or plan–do–study–act (PDSA). Another version of this PDCA cycle is OPDCA. The added "O" stands for observation or as some versions say "Grasp the current condition."" [PDCA. Wikipedia]

The Deming cycle diagrams sample "Design elements - PDCA" is included in Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

Use it to design your Deming cycle diagrams with ConceptDraw PRO software.

"PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continual improvement of processes and products. It is also known as the Deming circle/ cycle/ wheel, Shewhart cycle, control circle/ cycle, or plan–do–study–act (PDSA). Another version of this PDCA cycle is OPDCA. The added "O" stands for observation or as some versions say "Grasp the current condition."" [PDCA. Wikipedia]

The Deming cycle diagrams sample "Design elements - PDCA" is included in Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

This Deming cycle sample shows plan-do-check-act diagram.

It was designed on the base of Wikimedia Commons file: PDCA-Kreis (Qualitätsmanagement) mit Beschriftung.svg. [commons.wikimedia.org/ wiki/ File:PDCA-Kreis_ (Qualitätsmanagement)_ mit_ Beschriftung.svg]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"PDCA was made popular by Dr W. Edwards Deming, who is considered by many to be the father of modern quality control; however, he always referred to it as the "Shewhart cycle"." [PDCA. Wikipedia]

"Quality management ensures that an organization, product or service is consistent. It has four main components: quality planning, quality assurance, quality control and quality improvement. Quality management is focused not only on product and service quality, but also on the means to achieve it. Quality management, therefore, uses quality assurance and control of processes as well as products to achieve more consistent quality." [Quality management. Wikipedia]

The plan-do-check-act diagram example "Quality management PDCA" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

It was designed on the base of Wikimedia Commons file: PDCA-Kreis (Qualitätsmanagement) mit Beschriftung.svg. [commons.wikimedia.org/ wiki/ File:PDCA-Kreis_ (Qualitätsmanagement)_ mit_ Beschriftung.svg]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"PDCA was made popular by Dr W. Edwards Deming, who is considered by many to be the father of modern quality control; however, he always referred to it as the "Shewhart cycle"." [PDCA. Wikipedia]

"Quality management ensures that an organization, product or service is consistent. It has four main components: quality planning, quality assurance, quality control and quality improvement. Quality management is focused not only on product and service quality, but also on the means to achieve it. Quality management, therefore, uses quality assurance and control of processes as well as products to achieve more consistent quality." [Quality management. Wikipedia]

The plan-do-check-act diagram example "Quality management PDCA" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

This Deming cycle sample shows plan-do-check-act diagram.

It was designed on the base of Wikimedia Commons file: La roue de Deming pdca.jpg. [commons.wikimedia.org/ wiki/ File:La_ roue_ de_ Deming_ pdca.jpg]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"Shewhart described manufacture under "control"—under statistical control—as a three-step process of specification, production, and inspection. ...

Shewhart intended the analyst to take action based on the conclusions of the evaluation. According to Deming, during his lectures in Japan in the early 1950s, the Japanese participants shortened the steps to the now traditional plan, do, check, act. Deming preferred plan, do, study, act because "study" has connotations in English closer to Shewhart's intent than "check"." [PDCA. Wikipedia]

The plan-do-check-act diagram example "Deming PDCA" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

It was designed on the base of Wikimedia Commons file: La roue de Deming pdca.jpg. [commons.wikimedia.org/ wiki/ File:La_ roue_ de_ Deming_ pdca.jpg]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"Shewhart described manufacture under "control"—under statistical control—as a three-step process of specification, production, and inspection. ...

Shewhart intended the analyst to take action based on the conclusions of the evaluation. According to Deming, during his lectures in Japan in the early 1950s, the Japanese participants shortened the steps to the now traditional plan, do, check, act. Deming preferred plan, do, study, act because "study" has connotations in English closer to Shewhart's intent than "check"." [PDCA. Wikipedia]

The plan-do-check-act diagram example "Deming PDCA" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

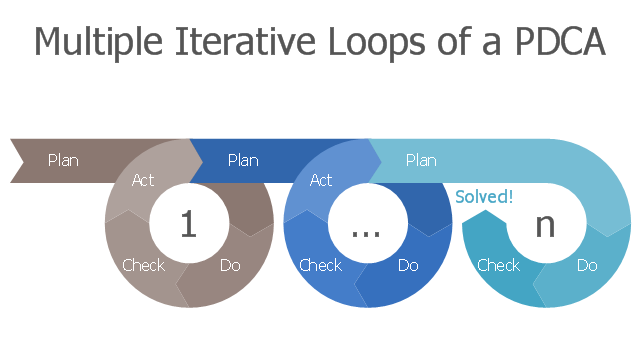

This Deming cycle sample shows multiloop plan-do-check-act diagram.

It was designed on the base of Wikimedia Commons file: PDCA-Multi-Loop.png.

"Multiple iterative loops of a PDCA (plan, do, check act) cycle, also known as Deming Cycle. The loops are repeated until the problem is solved." [commons.wikimedia.org/ wiki/ File:PDCA-Multi-Loop.png]

This file is licensed under the Creative Commons Attribution-Share Alike 4.0 International license. [creativecommons.org/ licenses/ by-sa/ 4.0/ deed.en]

The plan-do-check-act diagram example "Multiloop PDCA" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

It was designed on the base of Wikimedia Commons file: PDCA-Multi-Loop.png.

"Multiple iterative loops of a PDCA (plan, do, check act) cycle, also known as Deming Cycle. The loops are repeated until the problem is solved." [commons.wikimedia.org/ wiki/ File:PDCA-Multi-Loop.png]

This file is licensed under the Creative Commons Attribution-Share Alike 4.0 International license. [creativecommons.org/ licenses/ by-sa/ 4.0/ deed.en]

The plan-do-check-act diagram example "Multiloop PDCA" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

Fishbone Diagrams

Fishbone Diagrams

The Fishbone Diagrams solution extends ConceptDraw PRO v10 software with the ability to easily draw the Fishbone Diagrams (Ishikawa Diagrams) to clearly see the cause and effect analysis and also problem solving. The vector graphic diagrams produced using this solution can be used in whitepapers, presentations, datasheets, posters, and published technical material.

- New Plan - Do - Check - Act (PDCA) Addition to ConceptDraw Solution ...

- Fishbone Diagram | Entity-Relationship Diagram (ERD) | Plan - Do ...

- Plan - Do - Check - Act (PDCA) | How to Create PDCA Diagram ...

- How to Create PDCA Diagram | Plan - Do - Check - Act (PDCA ...

- How to Create PDCA Diagram | Circular arrows diagram - PDCA ...

- Process Flowchart | PM Planning | Plan - Do - Check - Act (PDCA ...

- Qms Process Flow Chart

- Circular arrows diagram - PDCA cycle

- Qms Document Control Symbol