"Root cause analysis (RCA) is a method of problem solving that tries to identify the root causes of faults or problems.

RCA practice tries to solve problems by attempting to identify and correct the root causes of events, as opposed to simply addressing their symptoms. Focusing correction on root causes has the goal of preventing problem recurrence. RCFA (Root Cause Failure Analysis) recognizes that complete prevention of recurrence by one corrective action is not always possible.

Conversely, there may be several effective measures (methods) that address the root causes of a problem. Thus, RCA is an iterative process and a tool of continuous improvement.

RCA is typically used as a reactive method of identifying event(s) causes, revealing problems and solving them. Analysis is done after an event has occurred. Insights in RCA may make it useful as a preemptive method. In that event, RCA can be used to forecast or predict probable events even before they occur. While one follows the other, RCA is a completely separate process to Incident Management." [Root cause analysis. Wikipedia]

The root cause analysis (RCA) tree diagram example "Manufacturing problem solution" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the solution "Seven Management and Planning Tools" from the Management area of ConceptDraw Solution Park.

RCA practice tries to solve problems by attempting to identify and correct the root causes of events, as opposed to simply addressing their symptoms. Focusing correction on root causes has the goal of preventing problem recurrence. RCFA (Root Cause Failure Analysis) recognizes that complete prevention of recurrence by one corrective action is not always possible.

Conversely, there may be several effective measures (methods) that address the root causes of a problem. Thus, RCA is an iterative process and a tool of continuous improvement.

RCA is typically used as a reactive method of identifying event(s) causes, revealing problems and solving them. Analysis is done after an event has occurred. Insights in RCA may make it useful as a preemptive method. In that event, RCA can be used to forecast or predict probable events even before they occur. While one follows the other, RCA is a completely separate process to Incident Management." [Root cause analysis. Wikipedia]

The root cause analysis (RCA) tree diagram example "Manufacturing problem solution" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the solution "Seven Management and Planning Tools" from the Management area of ConceptDraw Solution Park.

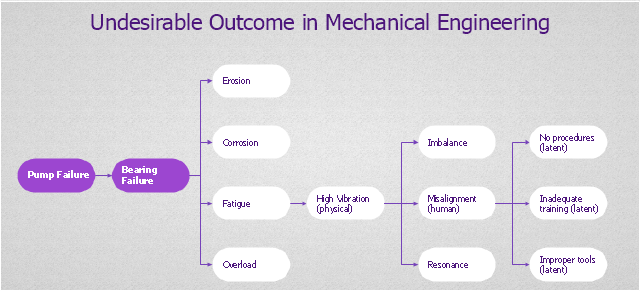

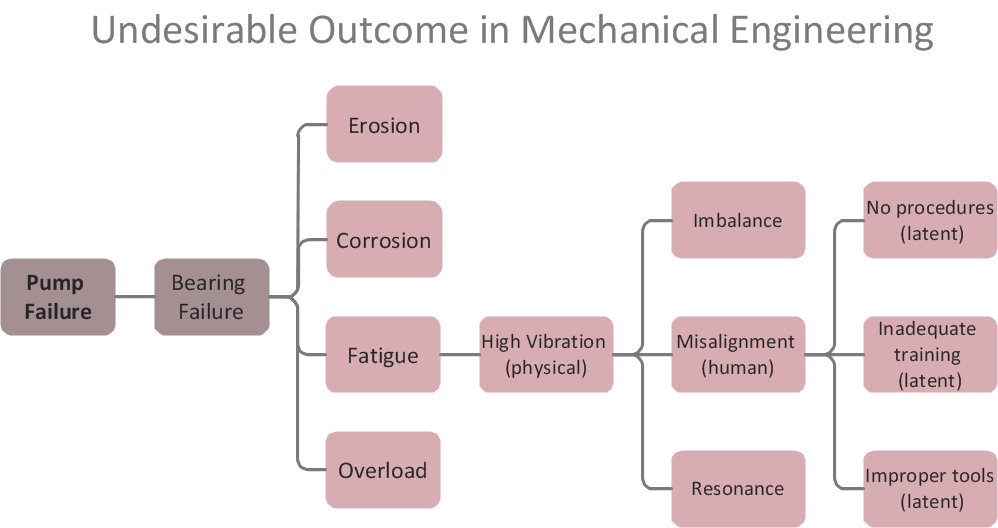

PROBLEM ANALYSIS. Root Cause Analysis Tree Diagram

Root Cause Analysis Tree Diagram. Use the Root Cause Diagram to perform visual root cause analysis. Root Cause Analysis Tree Diagram is constructed separately for each highly prioritized factor. The goal of this is to find the root causes for the factor and list possible corrective action. ConceptDraw Office suite is a software for problem analysis.

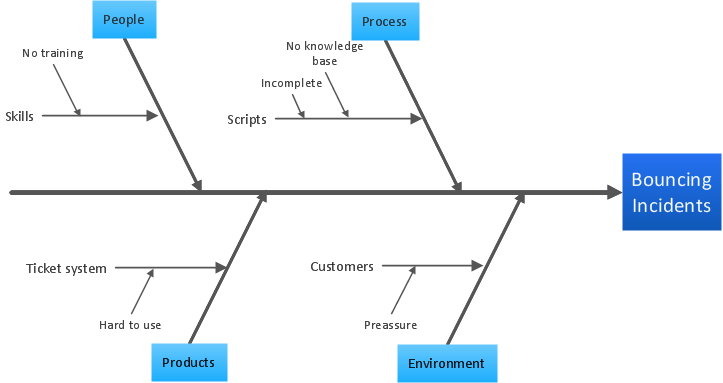

Cause and Effect Analysis - Fishbone Diagrams for Problem Solving

Fishbone diagram is a powerful tool used for solving business problems and obstacles. ConceptDraw PRO software extended with Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park is a helpful tool for cause and effect analysis. It gives the ability to easy identify many possible causes and factors which cause the effects and to draw Fishbone Diagrams for problem solving.

Seven Management and Planning Tools

Seven Management and Planning Tools

Seven Management and Planning Tools solution extends ConceptDraw PRO and ConceptDraw MINDMAP with features, templates, samples and libraries of vector stencils for drawing management mind maps and diagrams.

Root Cause Tree Diagram

The Root Cause Tree Diagram is a chart that helps determine the root causes of factors that influence the problem, to represent and analyze them. This diagram is constructed separately for each high priority factor. First it is needed to identify the root causes for a factor, display their structure and then propose the possible corrective actions. But how to create Root Cause Tree Diagram with the least efforts and time? ConceptDraw MINDMAP will effectively help you in drawing MINDMAP Root Cause Tree Diagram and Root Cause Analysis Tree Diagram used for further formulation of actions. The Root Cause Tree Diagram template, which can be opened at the program from the Input tab, supplies you with a basic mind map structure for your diagram. The central idea describes briefly a problem, the main topics represent the high-level causes of a problem, their subtopics give more details about the different parts of given causes. At the last level of tree are described the potential solutions to each of detailed parts of the causes.- PROBLEM ANALYSIS. Root Cause Analysis Tree Diagram | Root ...

- How Do Fishbone Diagrams Solve Manufacturing Problems ...

- Fault Tree Analysis Diagrams | PROBLEM ANALYSIS. Root Cause ...

- Root cause analysis tree diagram - Template

- Root cause analysis tree diagram - Manufacturing problem solution ...

- Root cause analysis tree diagram - Manufacturing problem solution

- Cause and Effect Analysis | PROBLEM ANALYSIS. Root Cause ...

- How To Create Root Cause Analysis Diagram Using ConceptDraw ...

- Example Of Manufacturing

- Fishbone Diagram Problem Solving | Root cause analysis tree ...

- Tree Diagrem For Various Manufacturing Process

- Venn Diagram Examples for Problem Solving. Computer Science ...

- PROBLEM ANALYSIS. Root Cause Analysis Tree Diagram ...

- Problem Analysis Example

- PROBLEM ANALYSIS. Root Cause Analysis Tree Diagram | Using ...

- Root cause analysis tree diagram - Sale problem solution | Root ...

- Example Manufacturing

- Swot Examples Manufacturing

- Manufacturing 8 Ms fishbone diagram - Template | Value-Stream ...

- Total value of manufacturers ' shipments | Average energy prices for ...