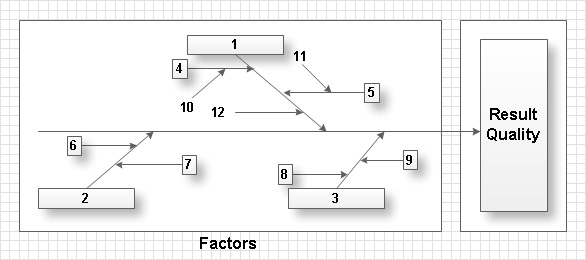

"Causes in the diagram are often categorized, such as to the 6 M's ...

The 6 Ms (used in manufacturing industry):

(1) Machine (technology);

(2) Method (process);

(3) Material (Includes Raw Material, Consumables and Information.);

(4) Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions;

(5) Measurement (Inspection);

(6) Milieu/ Mother Nature (Environment).

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

(7) Management/ Money Power;

(8) Maintenance." [Ishikawa diagram. Wikipedia]

This 8Ms Ishikawa diagram (manufacturing cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

The 6 Ms (used in manufacturing industry):

(1) Machine (technology);

(2) Method (process);

(3) Material (Includes Raw Material, Consumables and Information.);

(4) Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions;

(5) Measurement (Inspection);

(6) Milieu/ Mother Nature (Environment).

The original 6Ms used by the Toyota Production System have been expanded by some to include the following and are referred to as the 8Ms. However, this is not globally recognized. It has been suggested to return to the roots of the tools and to keep the teaching simple while recognizing the original intent; most programs do not address the 8Ms.

(7) Management/ Money Power;

(8) Maintenance." [Ishikawa diagram. Wikipedia]

This 8Ms Ishikawa diagram (manufacturing cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

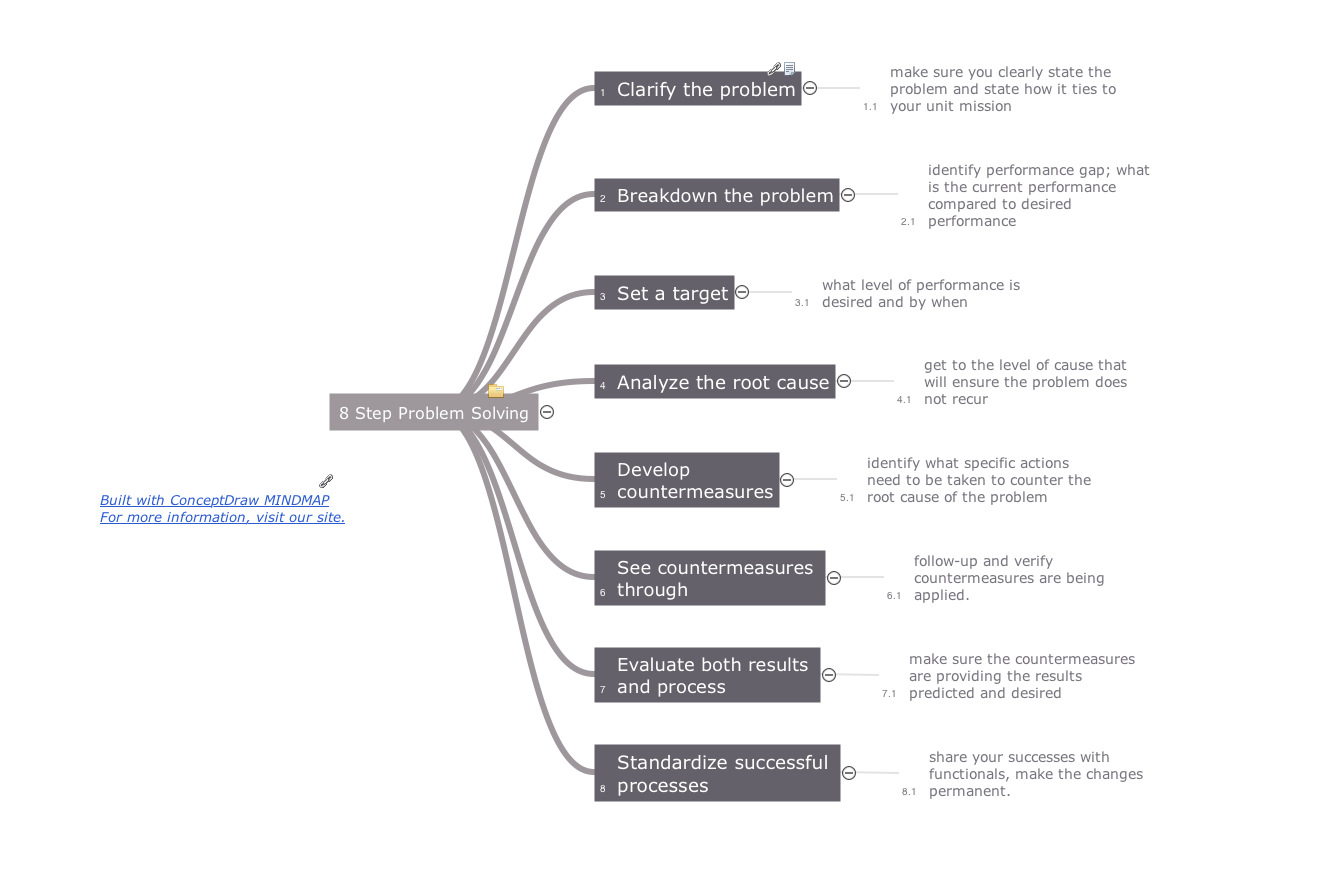

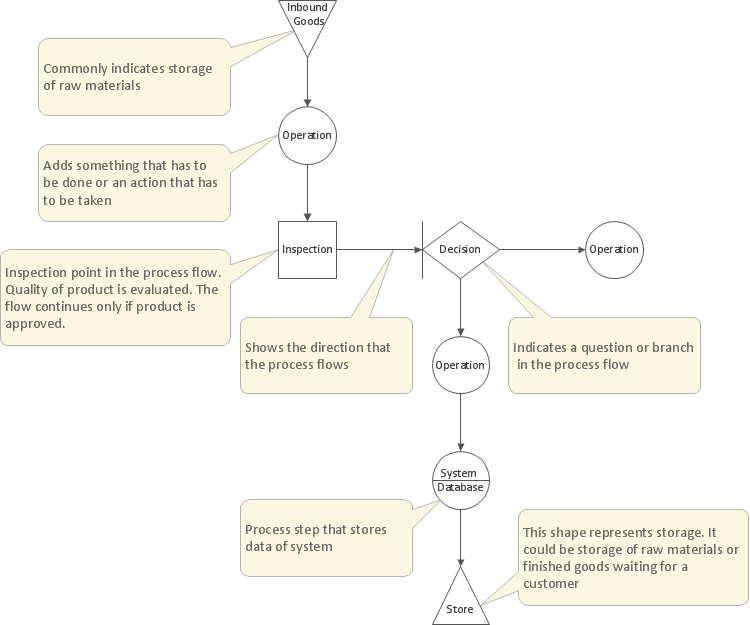

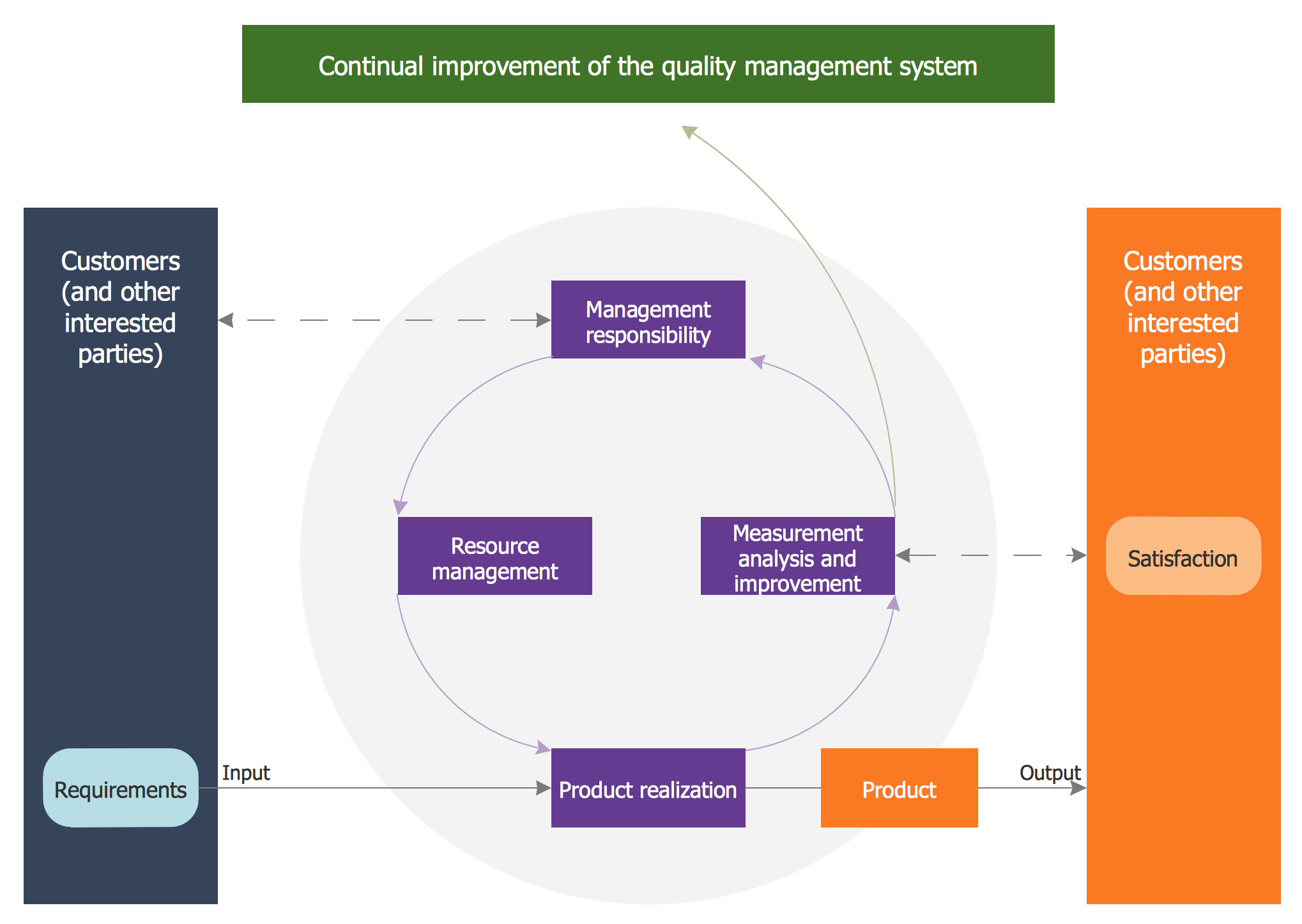

Total Quality Management Value

The Total quality management (TQM) is an enterprise-wide method of continuous quality improvement of all organizational processes, including the enhancement of ability to deliver high-quality products and services to the customers. The TQM includes eight main elements, which have great value: customer-focused, process-centered, total employee involvement, integrated system, continual improvement, strategic and systematic approach, fact-based decision making, communications. ConceptDraw DIAGRAM diagramming and vector drawing software offers the Total Quality Management Diagram solution with effective drawing tools, predesigned vector elements, samples and templates that help easy design the Total Quality Management diagrams, TQM flowcharts and Mind Maps widely used in quality management projects to visualize the business processes and industrial processes for your organization, to demonstrate the quality control step-by-step in a visual manner, to compare visually the ideal and real stages of processes.

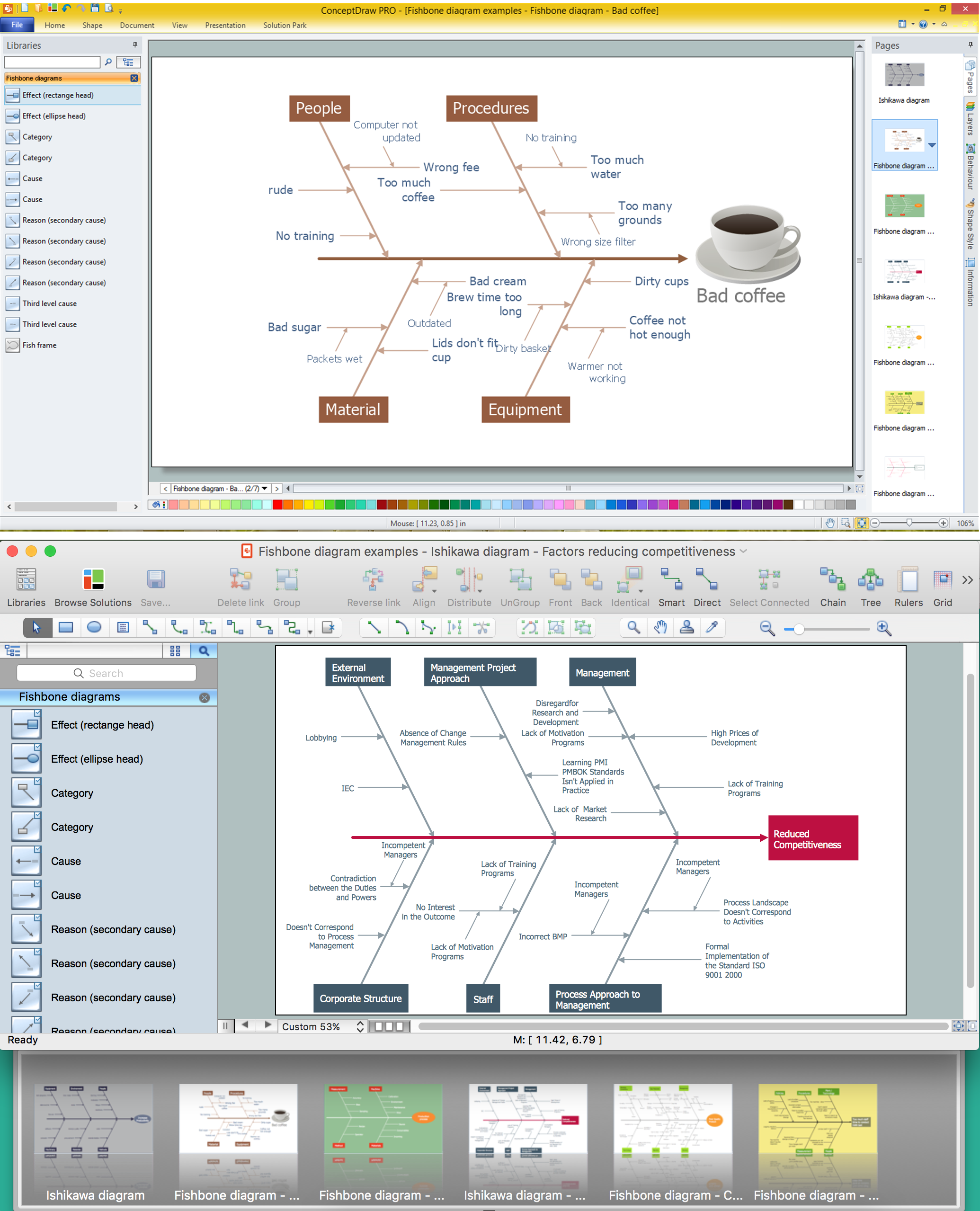

Fishbone Diagram

Fishbone Diagram

Fishbone Diagrams solution extends ConceptDraw DIAGRAM software with templates, samples and library of vector stencils for drawing the Ishikawa diagrams for cause and effect analysis.

Total Quality Management with ConceptDraw

Total Quality Management (TQM) system is the management method where the confidence in quality of all organization processes is placed foremost. The given method is widely used in production, in educational system, in government organizations and so on.Management Tools — Total Quality Management

The Total Quality Management Diagram solution helps your organization visualize business and industrial processes. Create Total Quality Management diagrams for business process with ConceptDraw software.Organizational Structure Total Quality Management

The Total Quality Management Diagram solution helps you and your organization visualize business and industrial processes. Create Total Quality Management diagrams for business process with ConceptDraw software.Using Fishbone Diagrams for Problem Solving

Problems are obstacles and challenges that one should overcome to reach the goal. They are an inseparable part of any business, and the success of an enterprise often depends on ability to solve all problems effectively. The process of problem solving often uses rational approach, helping to find a suitable solution. Using Fishbone Diagrams for Problem Solving is a productive and illustrative tool to identify the most important factors causing the trouble. ConceptDraw DIAGRAM extended with Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park is a powerful tool for problem solving with Fishbone Ishikawa diagram graphic method.Quality Management System

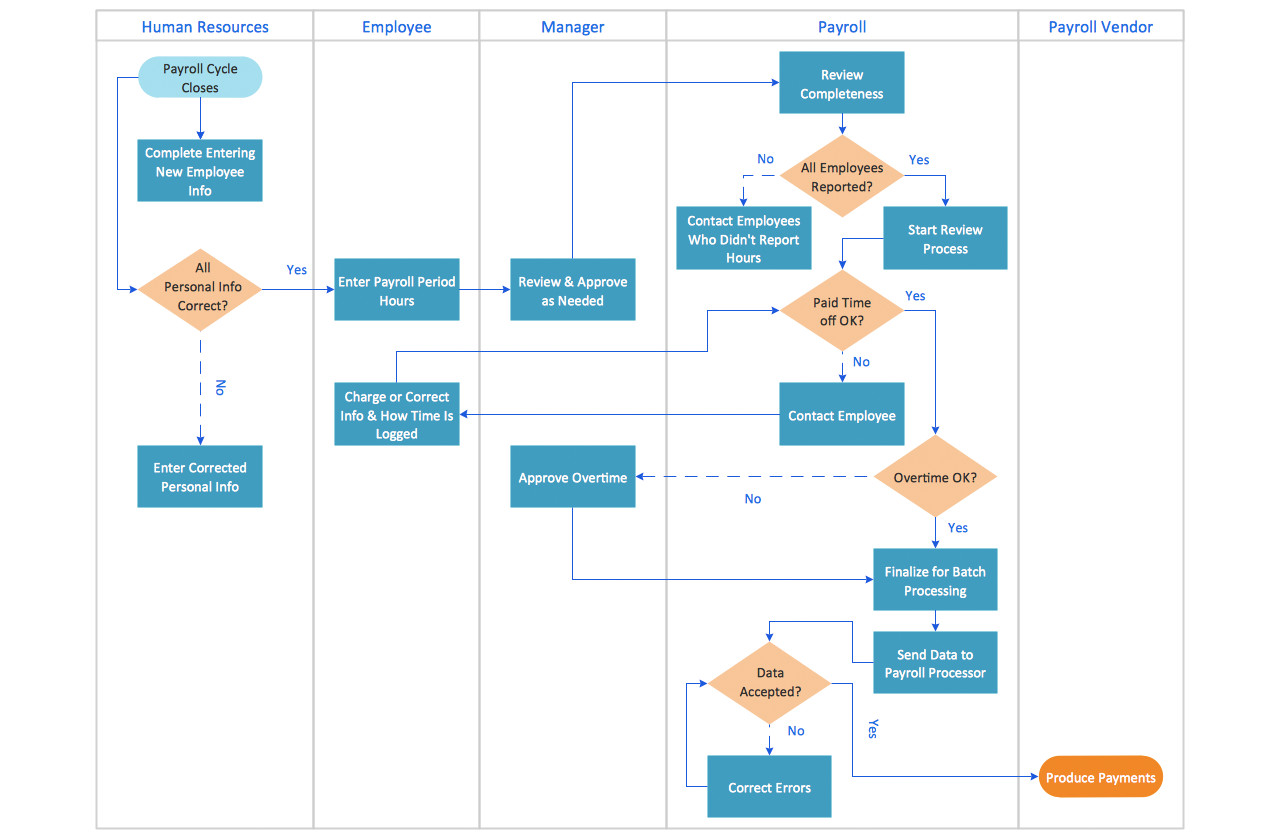

ConceptDraw DIAGRAM diagramming and vector drawing software extended with Total Quality Management (TQM) Diagrams solution from the Quality area of ConceptDraw Solution Park perfectly suits for development and visually representing a Quality Management System.Swim Lane Diagrams

Swim Lane Diagrams are the kind of process flow diagrams and effective tool for documenting the business processes required for any business company for its productive work, for easy defining the weak points, reasons of defects, or delays during the process. Swim Lane Diagram is based on the IDEF3 standard and was developed primarily for using in projecting. Its name derives from the use of horizontal or vertical lanes. The blocks that denote the parts of the processes are arranged within definite lanes according to the belonging to responsible worker. So the process of any complexity is visually divided into the parts and represented with indication the responsibility for execution of each part. This significantly facilitates the comprehension of its work. Use the ConceptDraw DIAGRAM software and predesigned vector objects from the Swim Lanes library of Business Process Mapping Solution included to ConceptDraw Solution Park to easy develop Swim Lanes Flowcharts and Diagrams, for modeling and documenting the business processes in a simple and visual graphic form.Quality Improvement

Constant improvement of key performance indicators that are related to quality is a step in the right direction for a company interested in market growth.TQM Diagram — Professional Total Quality Management

The Total Quality Management Diagram solution helps you and your organization visualize business and industrial processes. Create Total Quality Management diagrams for business process with ConceptDraw software.Quality Management Tools

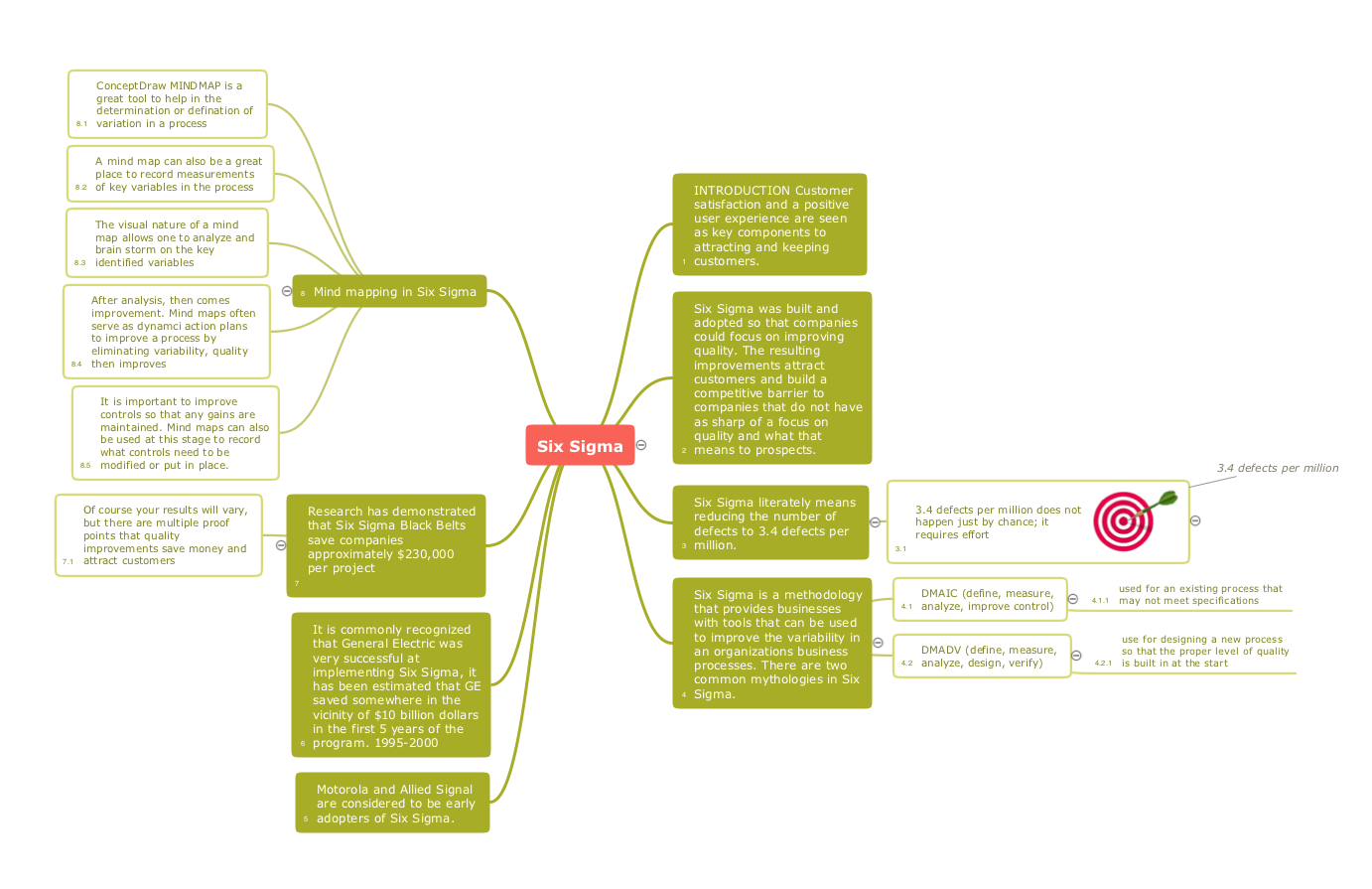

ConceptDraw DIAGRAM diagramming and vector drawing software offers at your disposal quality management tools of the Total Quality Management (TQM) Diagrams solution from the Quality area of ConceptDraw Solution Park which will help facilitate a drawing diagrams process for quality management.Quality Management Teams

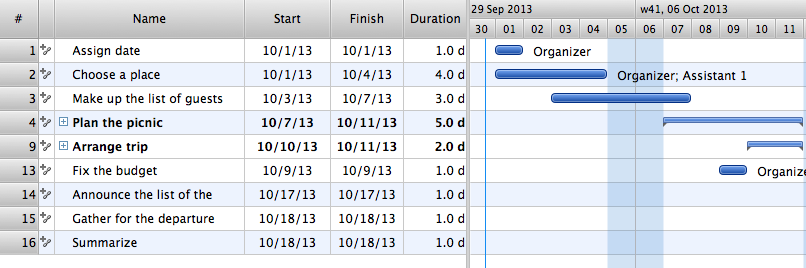

ConceptDraw MINDMAP with Quality mindmaps solution as a demonstration of the creative approach to quality management in daily work of quality management team.Managing the task list

Four lessons explaining how to manage your task list in a Gantt chart. You will learn how to adjust your Gantt chart view, how to add/delete tasks or subtasks, how to change tasks hierarchy, how to show/hide subtasks.- Fishbone diagram - Production process

- Total Quality Management Value | Manufacturing 8 Ms fishbone ...

- Fishbone diagram - Production process

- 4m Fishbone

- Manufacturing 8 Ms fishbone diagram - Template | Business ...

- Total Quality Management Value | Fishbone Diagram ...

- 4m Fishbone Diagram

- Total Quality Management Value | Manufacturing 8 Ms fishbone ...

- Total Quality Management Value | Manufacturing 8 Ms fishbone ...

- Manufacturing 8 Ms fishbone diagram - Template | Business ...

- Diagram Of Production Process

- Total Quality Management Value | Manufacturing 8 Ms fishbone ...

- Ishikawa Diagram | Total Quality Management Value | Using ...

- 4m Method

- 4m In Fishbone Diagram

- Manufacturing 8 Ms fishbone diagram - Template | Total Quality ...

- Production Management Diagram

- Total Quality Management Value | Manufacturing 8 Ms fishbone ...

- 4 M In Fishbone

- Total Quality Management Value | Manufacturing 8 Ms fishbone ...

-Diagram-in-SolutionBrowser.png)