"Business process improvement (BPI) is a systematic approach to help an organization optimize its underlying processes to achieve more efficient results. ...

An organization is only as good as its processes. To be able to make the necessary changes in an organization, one needs to understand the key processes of the company. Rummler and Brache suggested a model for running a Process Improvement and Management project (PI&M), containing the following steps:

1. Identify the process to be improved (based on a critical business issue): The identification of key processes can be a formal or informal exercise. The management team might select processes by applying a set of criteria derived from strategic and tactical priorities, or process selection is based on obvious performance gaps. It is important is to select the process(es) which have the greatest impact on a competitive advantage or customer requirement.

2. Develop the objective(s) for the project based on the requirements of the process: The focus might be on quality improvement, productivity, cost, customer service or cycle time. The goal is however always the same; to get the key process under control.

3. Select the members of the cross-functional team: A horizontal (cross-functional) analysis is carried out by a team composed of representatives of all functions involved in the process. While a consultant or in-house staff person can do the job, the quality of the analysis and the commitment to change is far greater with a cross-functional team.

4. Document the current process by creating a flowchart or "organization map": Describe the process regarding the Organizational level, the Process level and the Job/ Performer level according to Rummler. Develop a cross-functional process map for the process.

5. Identify "disconnects" in the process: “Disconnections” are everything that inhibit the efficiency and effectiveness of the process. The identification should be categorized into the three levels: The Organizational level, the Process level and the Job/ Performer level.

6. Recommend changes (organizational, in the process or in its execution): Categorize and prioritize the main problems and possibilities, evaluate alternative solutions. Develop a cross-functional process map for the recommended process.

7. Establish process and sub-process measures: The process measures should reflect the objectives of the project.

8. Implement the improvements." [Business process improvement. Wikipedia]

The opportunity flow chart example "Replacing engine oil" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Cross-Functional Flowcharts solution from the Business Processes area of ConceptDraw Solution Park.

An organization is only as good as its processes. To be able to make the necessary changes in an organization, one needs to understand the key processes of the company. Rummler and Brache suggested a model for running a Process Improvement and Management project (PI&M), containing the following steps:

1. Identify the process to be improved (based on a critical business issue): The identification of key processes can be a formal or informal exercise. The management team might select processes by applying a set of criteria derived from strategic and tactical priorities, or process selection is based on obvious performance gaps. It is important is to select the process(es) which have the greatest impact on a competitive advantage or customer requirement.

2. Develop the objective(s) for the project based on the requirements of the process: The focus might be on quality improvement, productivity, cost, customer service or cycle time. The goal is however always the same; to get the key process under control.

3. Select the members of the cross-functional team: A horizontal (cross-functional) analysis is carried out by a team composed of representatives of all functions involved in the process. While a consultant or in-house staff person can do the job, the quality of the analysis and the commitment to change is far greater with a cross-functional team.

4. Document the current process by creating a flowchart or "organization map": Describe the process regarding the Organizational level, the Process level and the Job/ Performer level according to Rummler. Develop a cross-functional process map for the process.

5. Identify "disconnects" in the process: “Disconnections” are everything that inhibit the efficiency and effectiveness of the process. The identification should be categorized into the three levels: The Organizational level, the Process level and the Job/ Performer level.

6. Recommend changes (organizational, in the process or in its execution): Categorize and prioritize the main problems and possibilities, evaluate alternative solutions. Develop a cross-functional process map for the recommended process.

7. Establish process and sub-process measures: The process measures should reflect the objectives of the project.

8. Implement the improvements." [Business process improvement. Wikipedia]

The opportunity flow chart example "Replacing engine oil" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Cross-Functional Flowcharts solution from the Business Processes area of ConceptDraw Solution Park.

Event-driven Process Chain Diagrams

Event-driven Process Chain Diagrams

Event-driven Process Chain (EPC) Diagram is a type of flowchart widely used for modeling in business engineering and reengineering, business process improvement, and analysis. EPC method was developed within the Architecture of Integrated Information Systems (ARIS) framework.

Seven Basic Tools of Quality

Seven Basic Tools of Quality

Manage quality control in the workplace, using fishbone diagrams, flowcharts, Pareto charts and histograms, provided by the Seven Basic Tools of Quality solution.

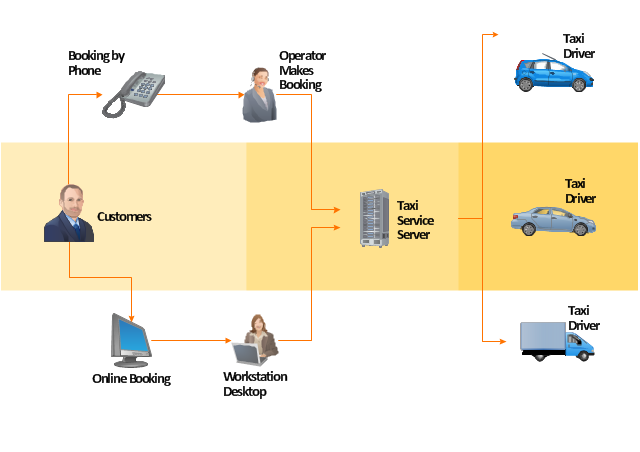

"A taxicab, also known as a taxi or a cab, is a type of vehicle for hire with a driver, used by a single passenger or small group of passengers often for a non-shared ride. A taxicab conveys passengers between locations of their choice. In modes of public transport, the pick-up and drop-off locations are determined by the service provider, not by the passenger, although demand responsive transport and share taxis provide a hybrid bus/ taxi mode.

There are four distinct forms of taxicab, which can be identified by slightly differing terms in different countries:

(1) Hackney carriages also known as public hire, hailed or street taxis, licensed for hailing throughout communities.

(2) Private hire vehicles, also known as minicabs or private hire taxis, licensed for pre-booking only.

(3) Taxibuses, also known as Jitneys, operating on pre-set routes typified by multiple stops and multiple independent passengers.

(4) Limousines, specialized vehicle licensed for operation by pre-booking.

Although types of vehicles and methods of regulation, hiring, dispatching, and negotiating payment differ significantly from country to country, many common characteristics exist." [Taxicab. Wikipedia]

The example "Workflow diagram - Taxi service" was drawn using the ConceptDraw PRO diagramming and vector drawing software extended with the Workflow Diagrams solution from the Business Processes area of ConceptDraw Solution Park.

There are four distinct forms of taxicab, which can be identified by slightly differing terms in different countries:

(1) Hackney carriages also known as public hire, hailed or street taxis, licensed for hailing throughout communities.

(2) Private hire vehicles, also known as minicabs or private hire taxis, licensed for pre-booking only.

(3) Taxibuses, also known as Jitneys, operating on pre-set routes typified by multiple stops and multiple independent passengers.

(4) Limousines, specialized vehicle licensed for operation by pre-booking.

Although types of vehicles and methods of regulation, hiring, dispatching, and negotiating payment differ significantly from country to country, many common characteristics exist." [Taxicab. Wikipedia]

The example "Workflow diagram - Taxi service" was drawn using the ConceptDraw PRO diagramming and vector drawing software extended with the Workflow Diagrams solution from the Business Processes area of ConceptDraw Solution Park.

Plumbing and Piping Plans

Plumbing and Piping Plans

Plumbing and Piping Plans solution extends ConceptDraw PRO v10.2.2 software with samples, templates and libraries of pipes, plumbing, and valves design elements for developing of water and plumbing systems, and for drawing Plumbing plan, Piping plan, PVC Pipe plan, PVC Pipe furniture plan, Plumbing layout plan, Plumbing floor plan, Half pipe plans, Pipe bender plans.

Mechanical Engineering

Mechanical Engineering

This solution extends ConceptDraw PRO v.9 mechanical drawing software (or later) with samples of mechanical drawing symbols, templates and libraries of design elements, for help when drafting mechanical engineering drawings, or parts, assembly, pneumatic,

- Types Of Motors Flowchart

- How To Motor Heating Types Flowchart

- Types Of Motor Flow Chart

- Process Flowchart | Basic Flowchart Symbols and Meaning | Flow ...

- Flow Chart Of Types Of Motors

- Flow Process Chart Worker Type For Motor Car

- Process Flowchart | Types of Flowcharts | Electrical Symbols ...

- Electrical Symbols, Electrical Diagram Symbols | Process Flowchart ...

- Motor Types In Flowchart

- What Are Five Symbols In Operations Flow Chart In Motor Engine Oil

- Process Flowchart | Mechanical Drawing Symbols | Design ...

- Process Flowchart | Types of Flowchart - Overview | Event-Driven ...

- Process Flowchart | Basic Flowchart Symbols and Meaning | Flow ...

- Motor Creating Components Flow Chart

- Mechanical Drawing Symbols | Flowchart Maker | Technical ...

- Process Flowchart | Mechanical Drawing Symbols | How To use ...

- Sample Process Flow Chart For Motor Oil Manufactur

- Basic Flowchart Symbols and Meaning | Process Flowchart | Design ...

- Process Flowchart | Types of Flowcharts | Mechanical Design ...

- Process Flowchart | Process Flow Diagram Symbols | Total Quality ...