Value Stream Mapping for the Lean Office

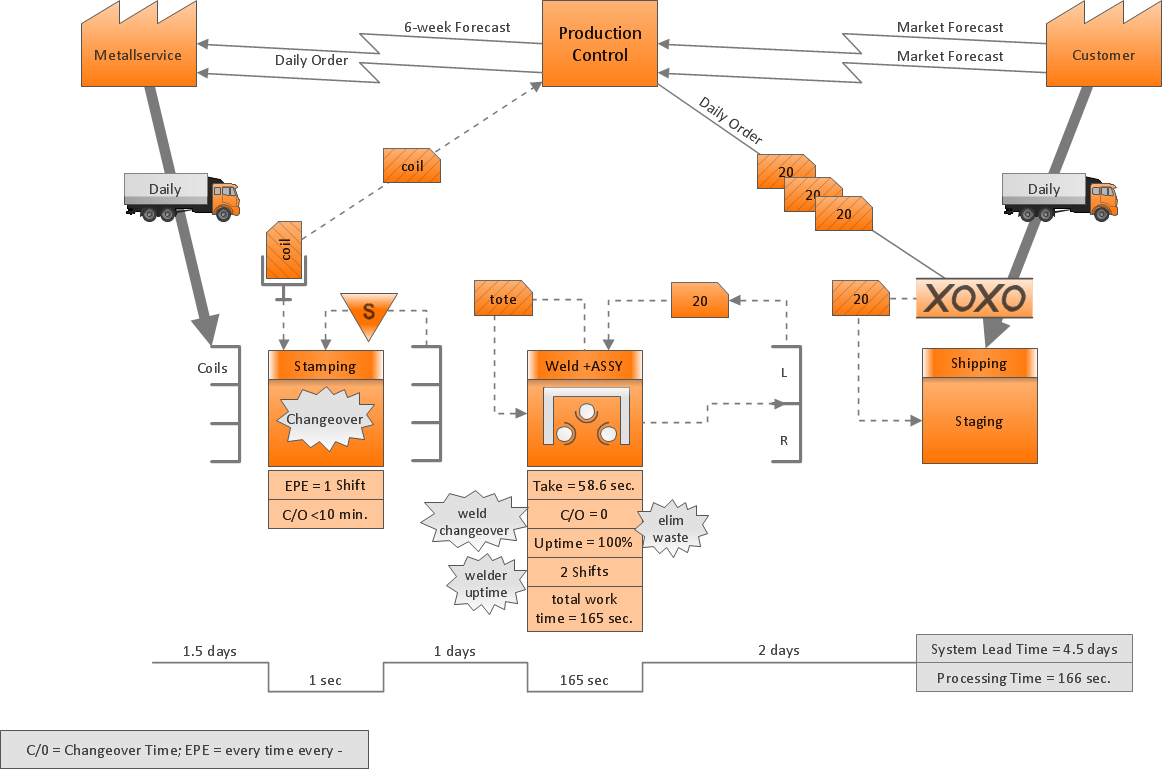

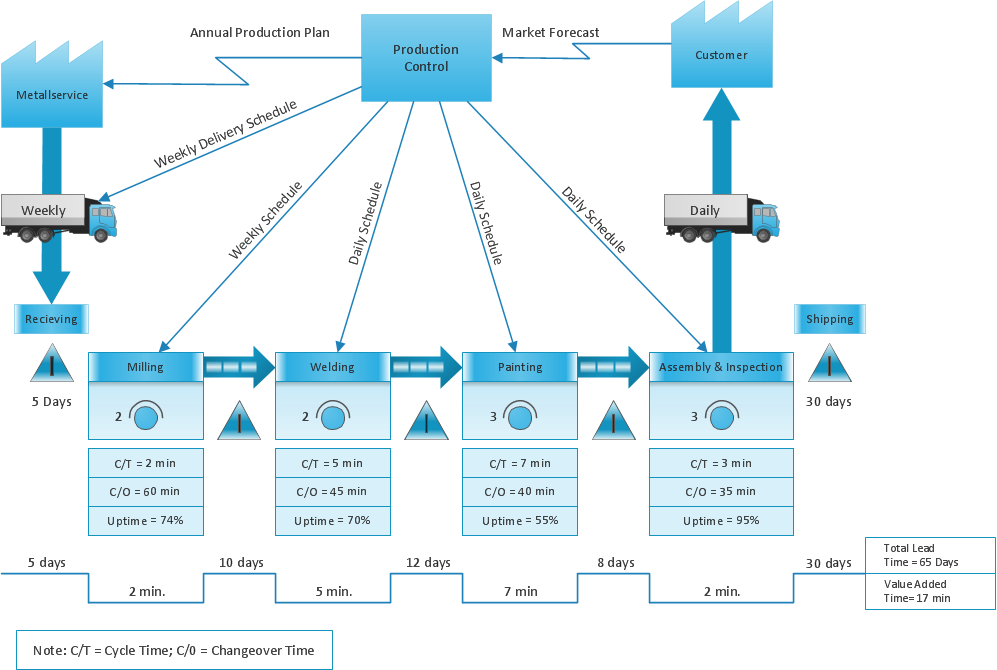

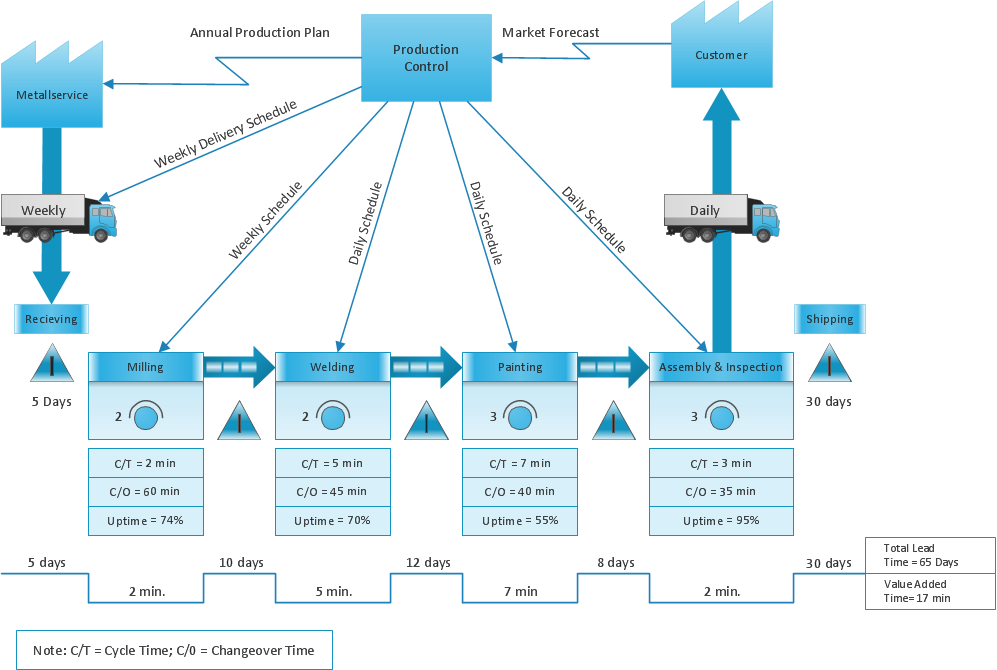

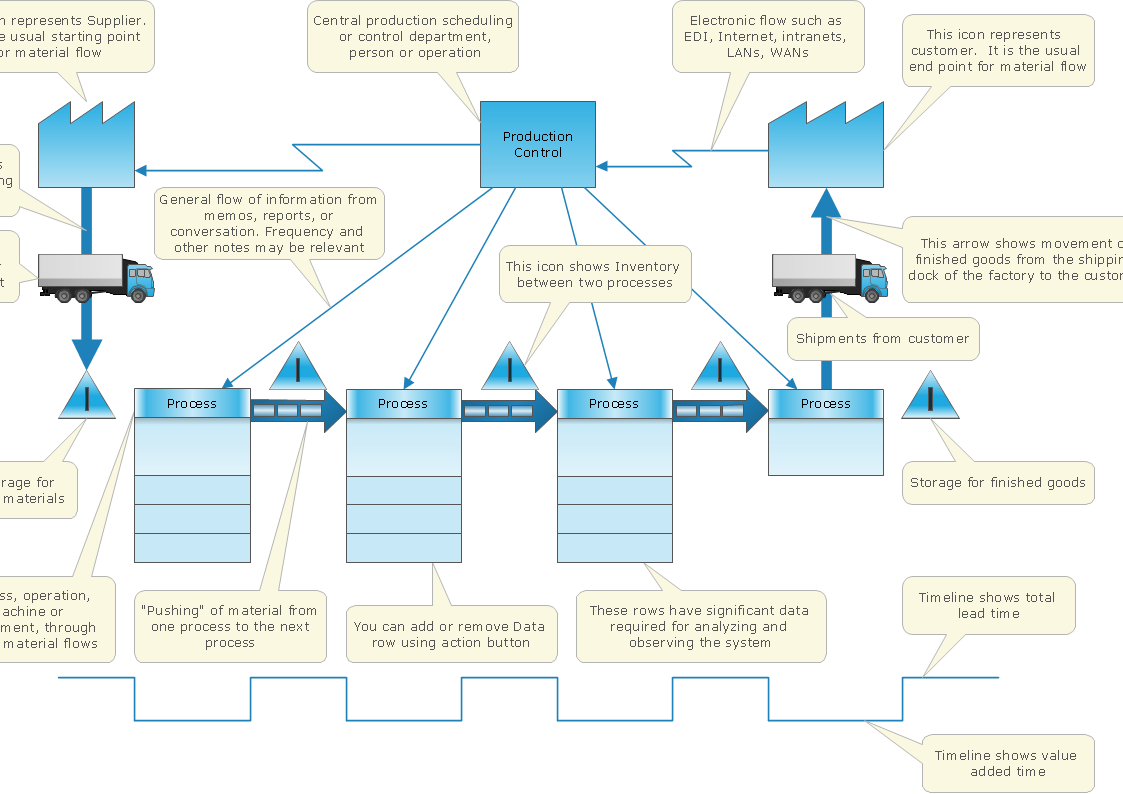

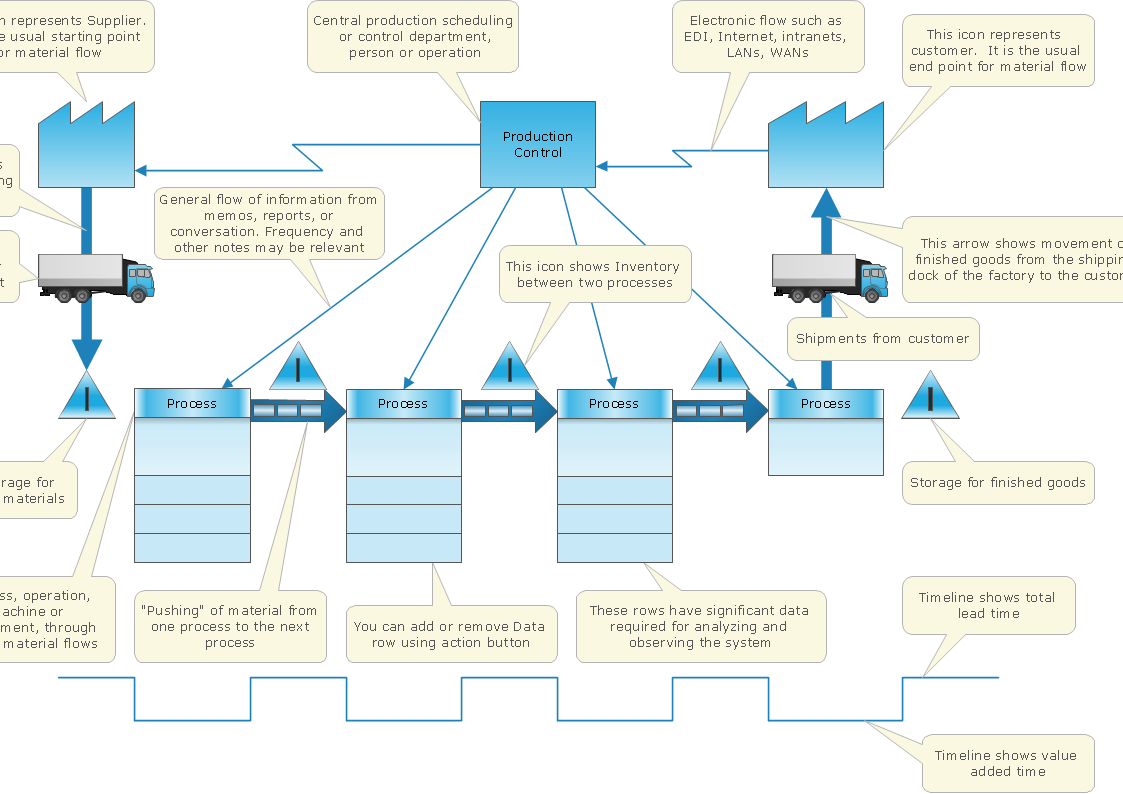

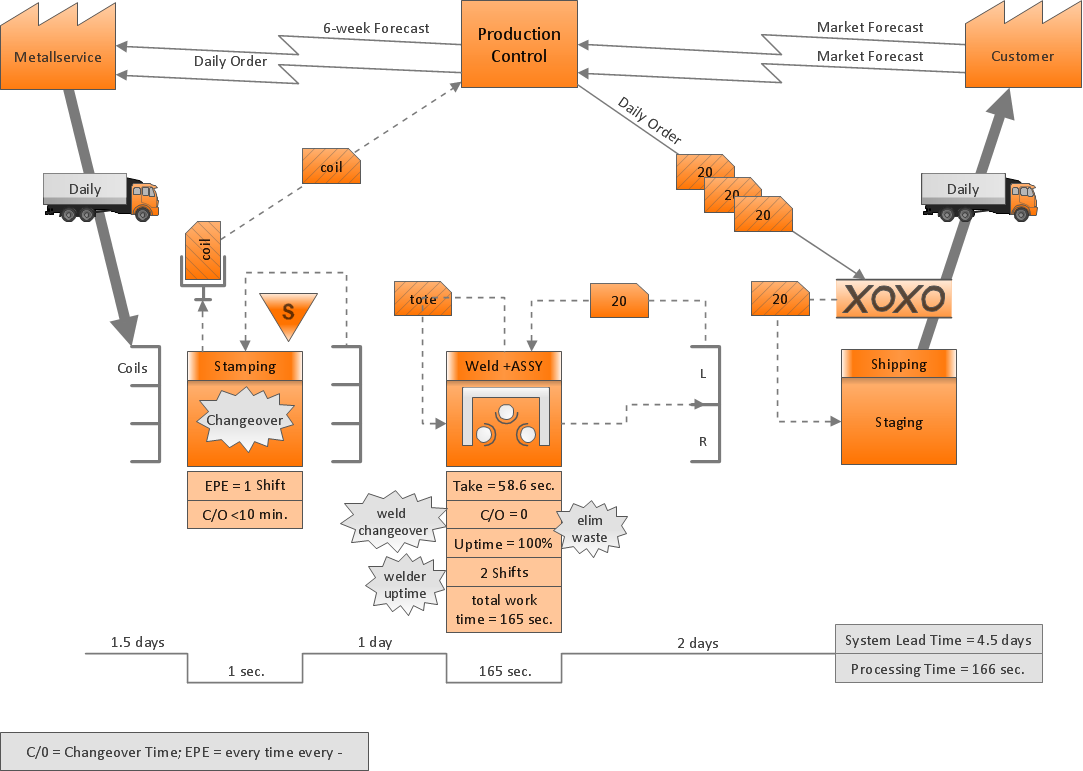

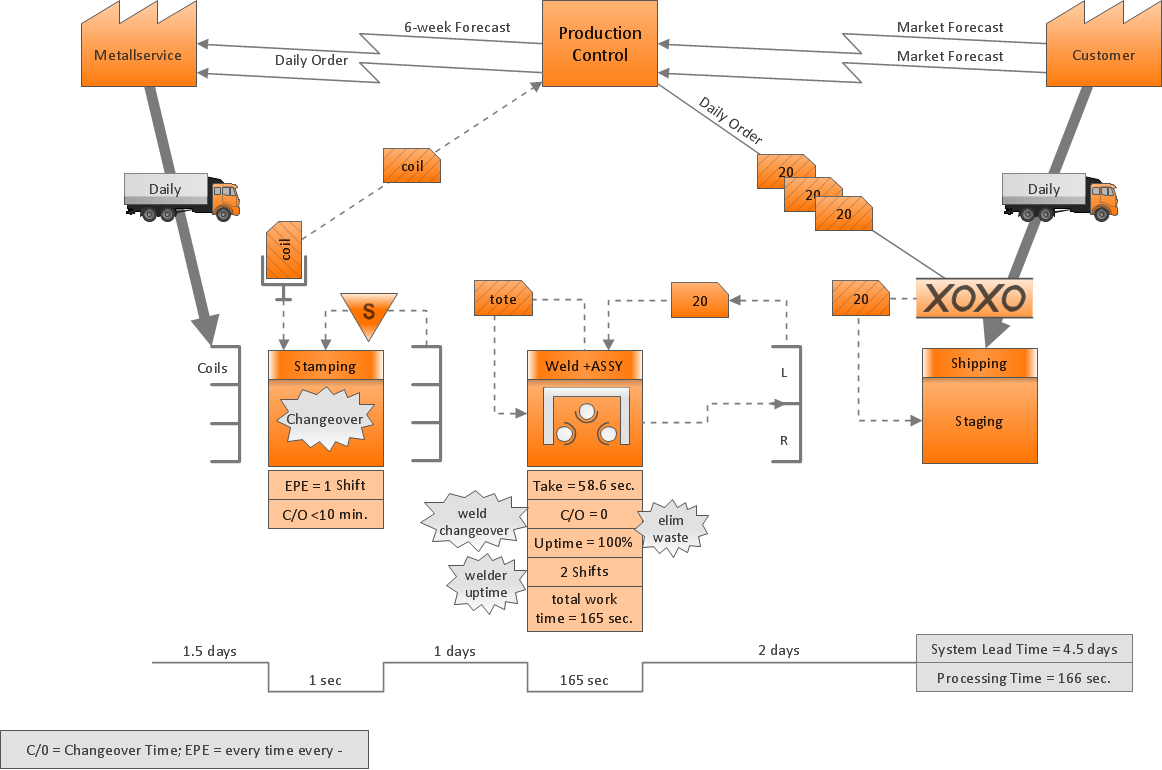

Value Stream Mapping for the lean office is a tool that uses a flow diagram to document in great detail every step of a manufacturing process.The Lean Enterprise Value Stream Mapping

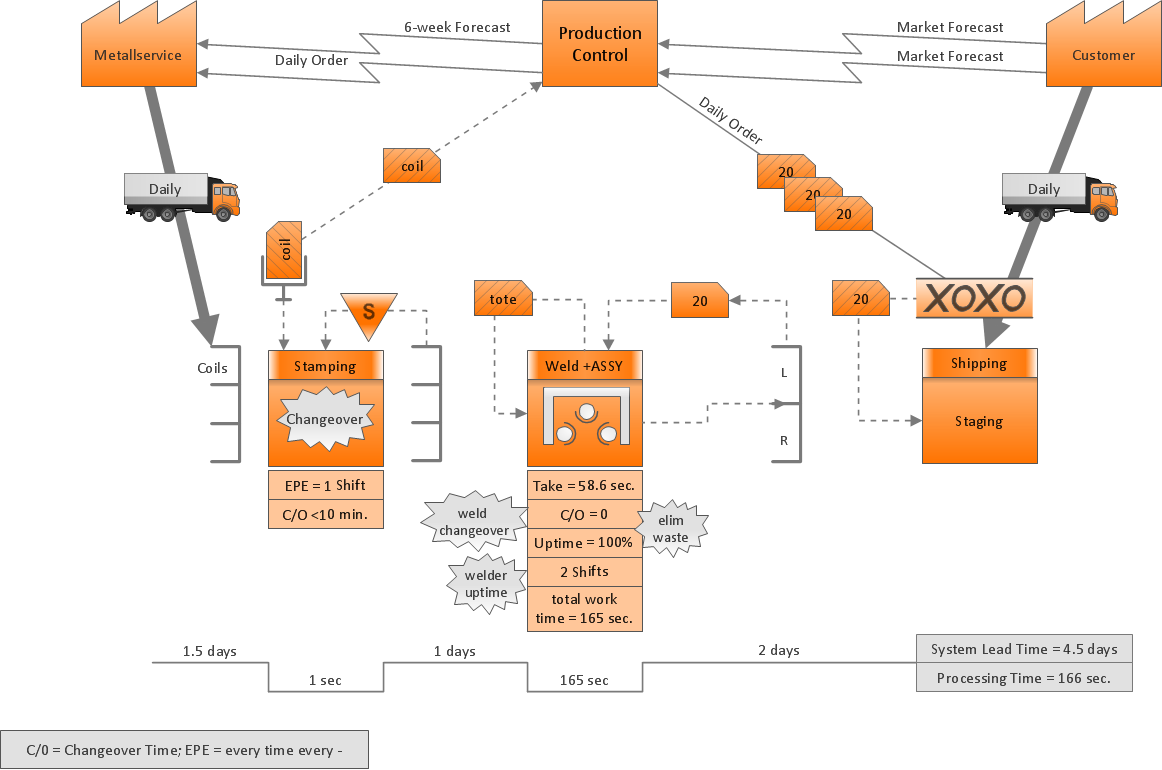

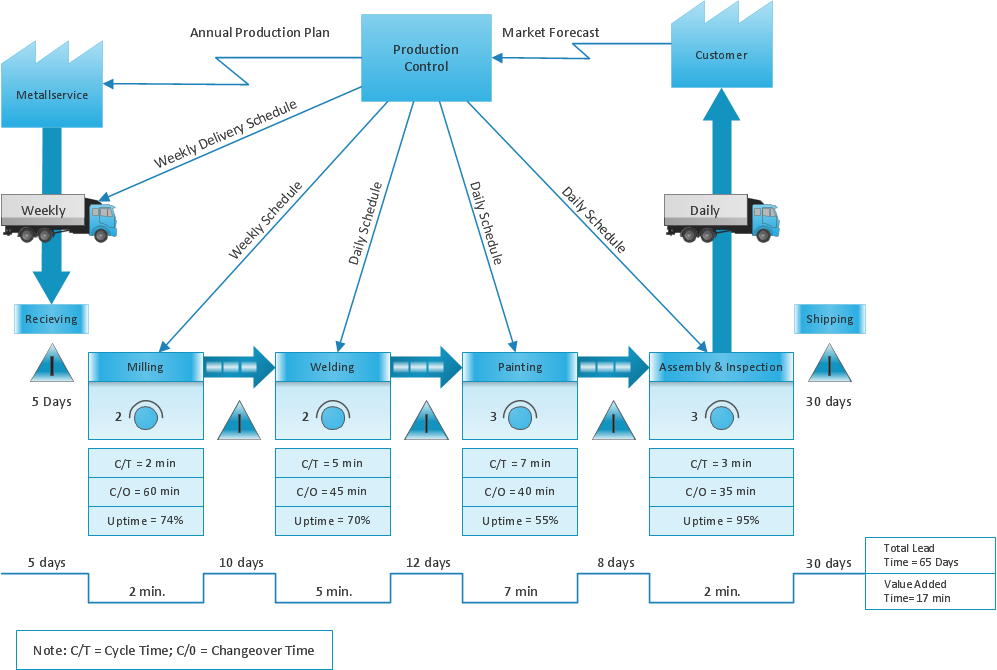

Create value stream maps - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.Lean Value Stream Map

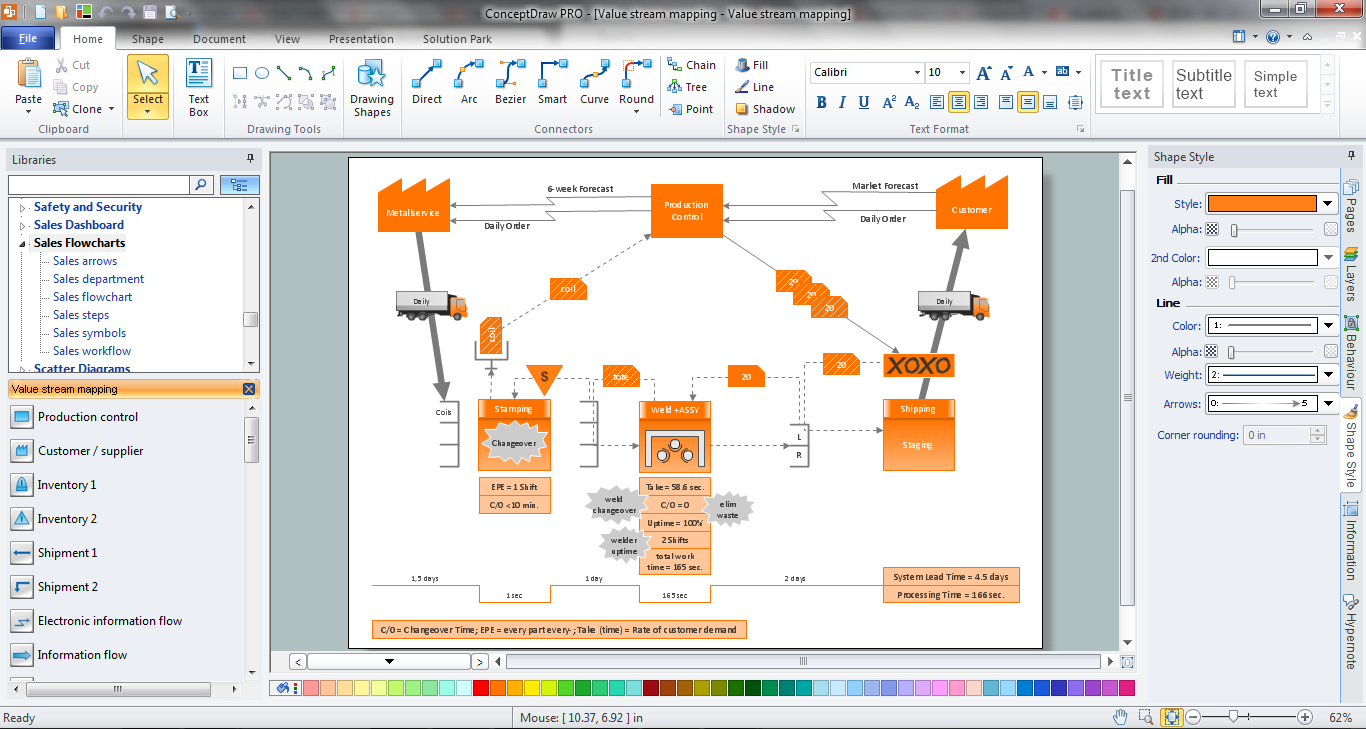

Lean Manufacturing tool is a new Value Stream Mapping solution found in the ConceptDraw Solution Park.Lean Manufacturing Diagrams

The Value Stream Mapping solution continues to extend the range of ConceptDraw PRO into a business graphics tool that can be used to document processes of Lean Manufacturing.Lean Value Stream

ConceptDraw Value Stream Mapping is a Lean Manufacturing tool that uses a flow diagram to document in great detail every step of a manufacturing process.Value-Stream Mapping for Manufacturing

Create value stream maps - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.Mind Mapping in the Quality Management

ConceptDraw MINDMAP has a addition to the ConceptDraw Solution Park that provides a creative approach to visualizing quality processes, Quality Mind Map Solution.Value Stream Mapping and Analysis

Value Stream Maps are used in lean methodology for analysis of manufacturing process and identification of the improvement opportunities.Create a Value Stream Map

Use ConceptDraw PRO software extended with Value Stream Mapping solution to create your own VSM diagrams.Learn how to create a current state value stream map

Value Stream Mapping solution extends ConceptDraw PRO software with templates, samples and vector shapes for drawing the current state value stream maps.Purposes of a Value Stream Management Tool

ConceptDraw Value Stream Maps visualize for a manufacturing plant the material and information flow required to deliver a product/service to customers.Best Value Stream Mapping mac Software

Create value stream maps - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.Value Stream Analysis

ConceptDraw Value Stream Maps are used in lean practice for analysis of manufacturing processes to identify the improvement opportunities.Value Stream Mapping Icons

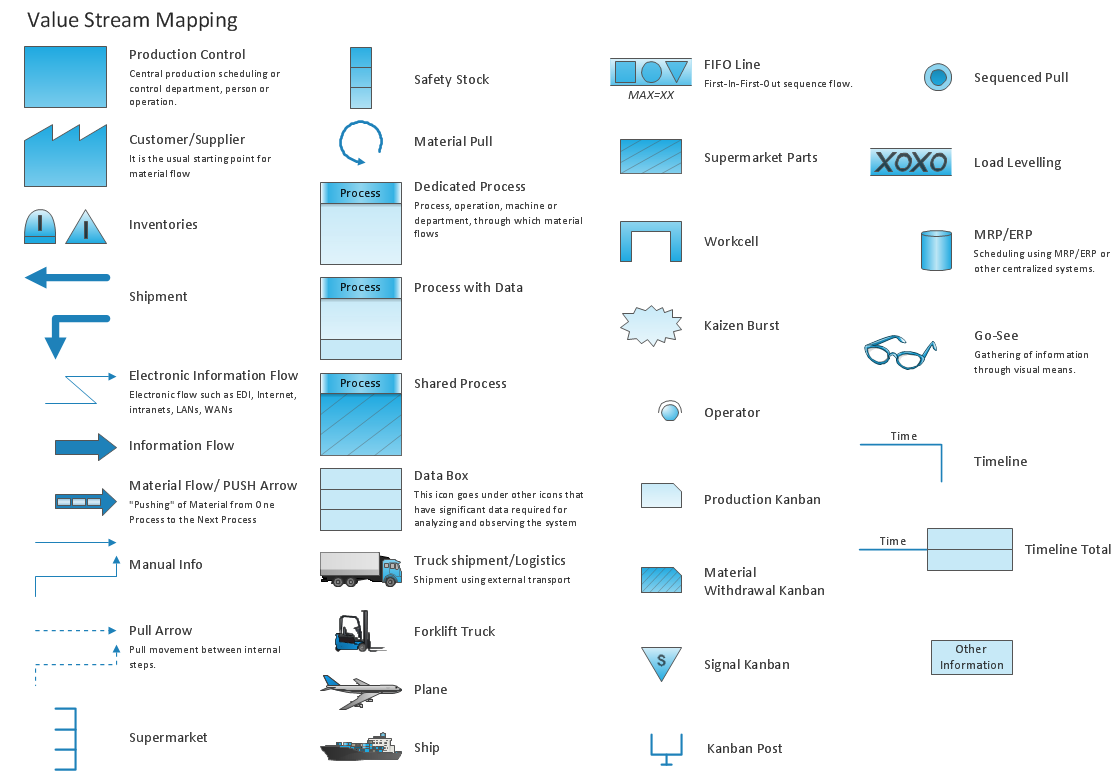

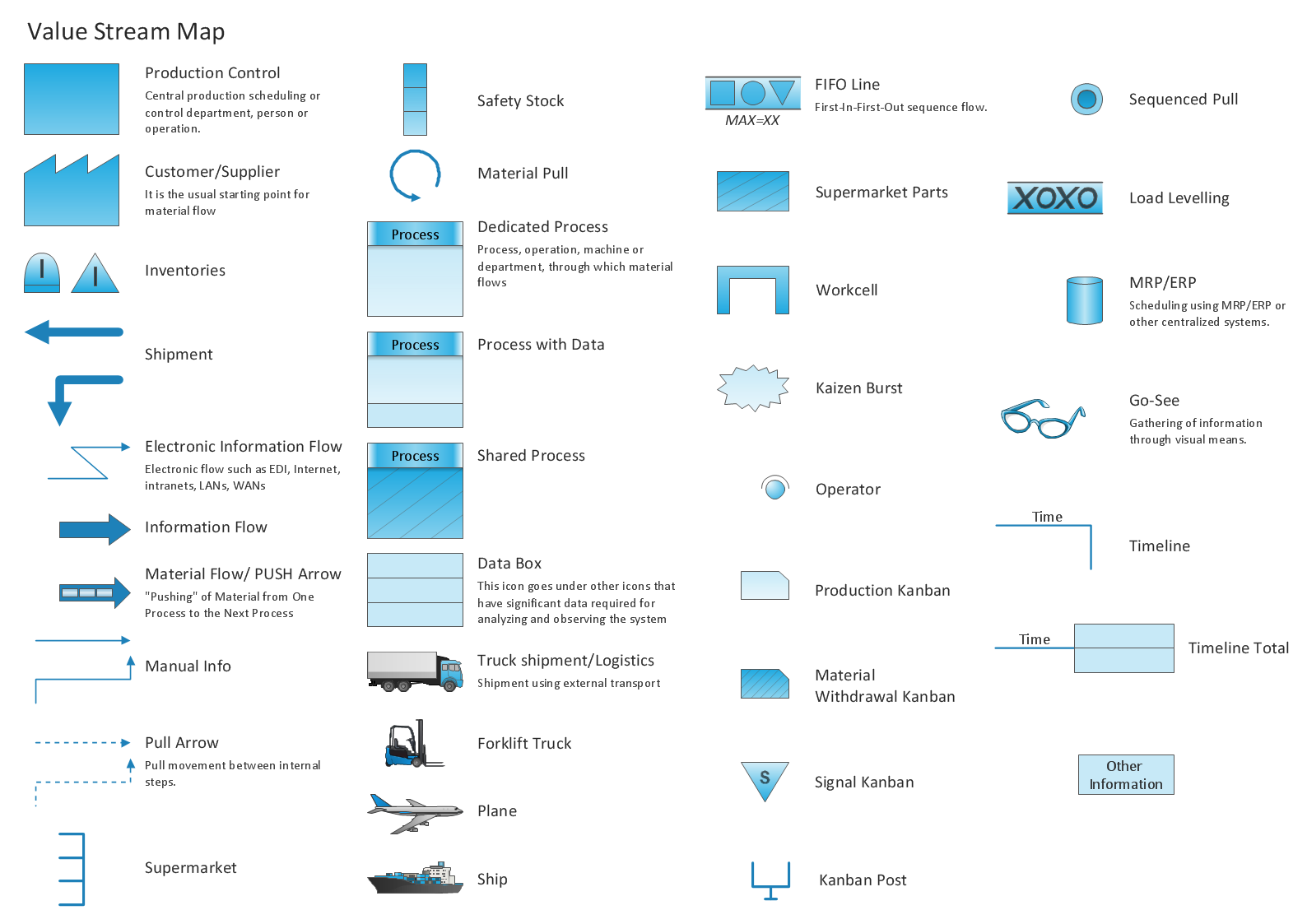

The library with 40 vector stencils is included in the ConceptDraw Value Stream Mapping solution.Value Stream Mapping

Use ConceptDraw Value Stream Maps (VSM) visualization for a manufacturing plant the material and information flow required to deliver a product/service to customers. The new Value Stream Mapping solution found in the ConceptDraw Solution Park continues to extend the range of ConceptDraw PRO into a business graphics tool that can be used to document processes in any organization.- Manufacturing 8 Ms fishbone diagram - Template | Business ...

- Lean Value Stream Map

- Lean Manufacturing Diagrams | Value Stream Mapping for the Lean ...

- Lean Manufacturing Diagrams | Value Stream Mapping for the Lean ...

- Lean Manufacturing Diagrams | Manufacturing 8 Ms fishbone ...

- Process Improvement Value Stream Mapping

- Affinity diagram - Implementing continuous process improvement

- Fishbone Diagram | Lean Manufacturing Diagrams | Bar Diagrams ...

- The Best Tool for Business Process Modeling | PROBLEM ...

- Manufacturing 8 Ms fishbone diagram - Template | Manufacturing ...

- Circular arrows diagram

- Seven Management and Planning Tools | Affinity diagram ...

- Circular arrows diagram - PDCA cycle

- EPC for Business Process Improvement | Affinity diagram ...

- Manufacturing 8 Ms fishbone diagram - Template | Manufacturing ...

- Process Flowchart | Strategic planning - Cycle diagram | Circular ...

- How to Draw a Circular Arrows Diagram Using ConceptDraw PRO ...

- Circular arrows diagram - BPM life cycle

- Value-Stream Mapping for Manufacturing | Business Productivity ...

- Circular Arrows Diagrams | Basic Diagramming | Circular arrows ...