- Electric and Telecom Plans Free

- Fire and Emergency Plans Free

- Floor Plans Free

- Plant Layout Plans Free

- School and Training Plans Free

- Seating Plans Free

- Security and Access Plans Free

- Site Plans Free

- Sport Field Plans Free

- Business Process Diagrams Free

- Business Process Mapping Free

- Classic Business Process Modeling Free

- Cross-Functional Flowcharts Free

- Event-driven Process Chain Diagrams Free

- IDEF Business Process Diagrams Free

- Logistics Flow Charts Free

- Workflow Diagrams Free

- ConceptDraw Dashboard for Facebook Free

- Mind Map Exchange Free

- MindTweet Free

- Note Exchange Free

- Project Exchange Free

- Social Media Response Free

- Active Directory Diagrams Free

- AWS Architecture Diagrams Free

- Cisco Network Diagrams Free

- Cisco Networking Free

- Cloud Computing Diagrams Free

- Computer Network Diagrams Free

- Google Cloud Platform Free

- Interactive Voice Response Diagrams Free

- Network Layout Floor Plans Free

- Network Security Diagrams Free

- Rack Diagrams Free

- Telecommunication Network Diagrams Free

- Vehicular Networking Free

- Wireless Networks Free

- Comparison Dashboard Free

- Composition Dashboard Free

- Correlation Dashboard Free

- Frequency Distribution Dashboard Free

- Meter Dashboard Free

- Spatial Dashboard Free

- Status Dashboard Free

- Time Series Dashboard Free

- Basic Circle-Spoke Diagrams Free

- Basic Circular Arrows Diagrams Free

- Basic Venn Diagrams Free

- Block Diagrams Free

- Concept Maps Free

- Family Tree Free

- Flowcharts Free

- Basic Area Charts Free

- Basic Bar Graphs Free

- Basic Divided Bar Diagrams Free

- Basic Histograms Free

- Basic Line Graphs Free

- Basic Picture Graphs Free

- Basic Pie Charts Free

- Basic Scatter Diagrams Free

- Aerospace and Transport Free

- Artwork Free

- Audio, Video, Media Free

- Business and Finance Free

- Computers and Communications Free

- Holiday Free

- Manufacturing and Maintenance Free

- Nature Free

- People Free

- Presentation Clipart Free

- Safety and Security Free

- Audio and Video Connectors Free

- Basic Circuit Diagrams Free

- Chemical and Process Engineering Free

- Digital Electronics Free

- Electrical Engineering Free

- Electron Tube Circuits Free

- Fault Tree Analysis Diagrams Free

- GHS Hazard Pictograms Free

- Home Automation and Wiring Free

- Mechanical Engineering Free

- Specification and Description Language (SDL) Free

- Transport Hazard Pictograms Free

- Data-driven Infographics Free

- Pictorial Infographics Free

- Spatial Infographics Free

- Typography Infographics Free

- Calendars Free

- Decision Making Free

- Enterprise Architecture Diagrams Free

- Fishbone Diagrams Free

- Organizational Charts Free

- Plan-Do-Check-Act (PDCA) Free

- Seven Management and Planning Tools Free

- SWOT and TOWS Matrix Diagrams Free

- Timeline Diagrams Free

- Australia Map Free

- Continent Maps Free

- Directional Maps Free

- Germany Map Free

- Metro Map Free

- UK Map Free

- USA Maps Free

- Customer Journey Mapping Free

- Marketing Diagrams Free

- Matrices Free

- Pyramid Diagrams Free

- Sales Dashboard Free

- Sales Flowcharts Free

- Target and Circular Diagrams Free

- Cash Flow Reports Free

- Current Activities Reports Free

- Custom Excel Report Free

- Knowledge Reports Free

- MINDMAP Reports Free

- Overview Reports Free

- PM Agile Free

- PM Dashboards Free

- PM Docs Free

- PM Easy Free

- PM Meetings Free

- PM Planning Free

- PM Presentations Free

- PM Response Free

- Resource Usage Reports Free

- Visual Reports Free

- House of Quality Free

- Quality Mind Map Free

- Total Quality Management TQM Diagrams Free

- Value Stream Mapping Free

- Android User Interface Free

- Data Flow Diagrams (DFD) Free

- Entity-Relationship Diagram (ERD) Free

- EXPRESS-G data Modeling Diagram Free

- IDEF0 Diagrams Free

- iPhone User Interface Free

- Jackson Structured Programming (JSP) Diagrams Free

- macOS User Interface Free

- Object-Role Modeling (ORM) Diagrams Free

- Rapid UML Free

- SYSML Free

- Website Wireframe Free

- Windows 10 User Interface Free

House of Quality

Each successful company tries to use all variety of data and information during the process of planning, development, manufacturing, selling and promotion on the market the new prospective product or service. The process of planning new product, the market research, the application of quality management methods, quality control, total quality management and other innovative methods, as well as compliance to the requirements of the international standards, such as ISO 9001, are very important actions, which in much determine the future success of currently created product. The planning of new product includes the steps of studying demand, the comparing of competing products, the learning of information about customer requirements and their satisfaction with similar products. The most popular method, which allows identifying, classifying and transforming the clients’ needs and desires into the products engineering characteristics, identifying and setting priorities for each product and service, and simultaneously determining the objectives of production development, is the Quality function deployment (QFD) method. Appeared in Japan in 1972, this method is now quite popular and widely used in manufacturing areas of many countries.

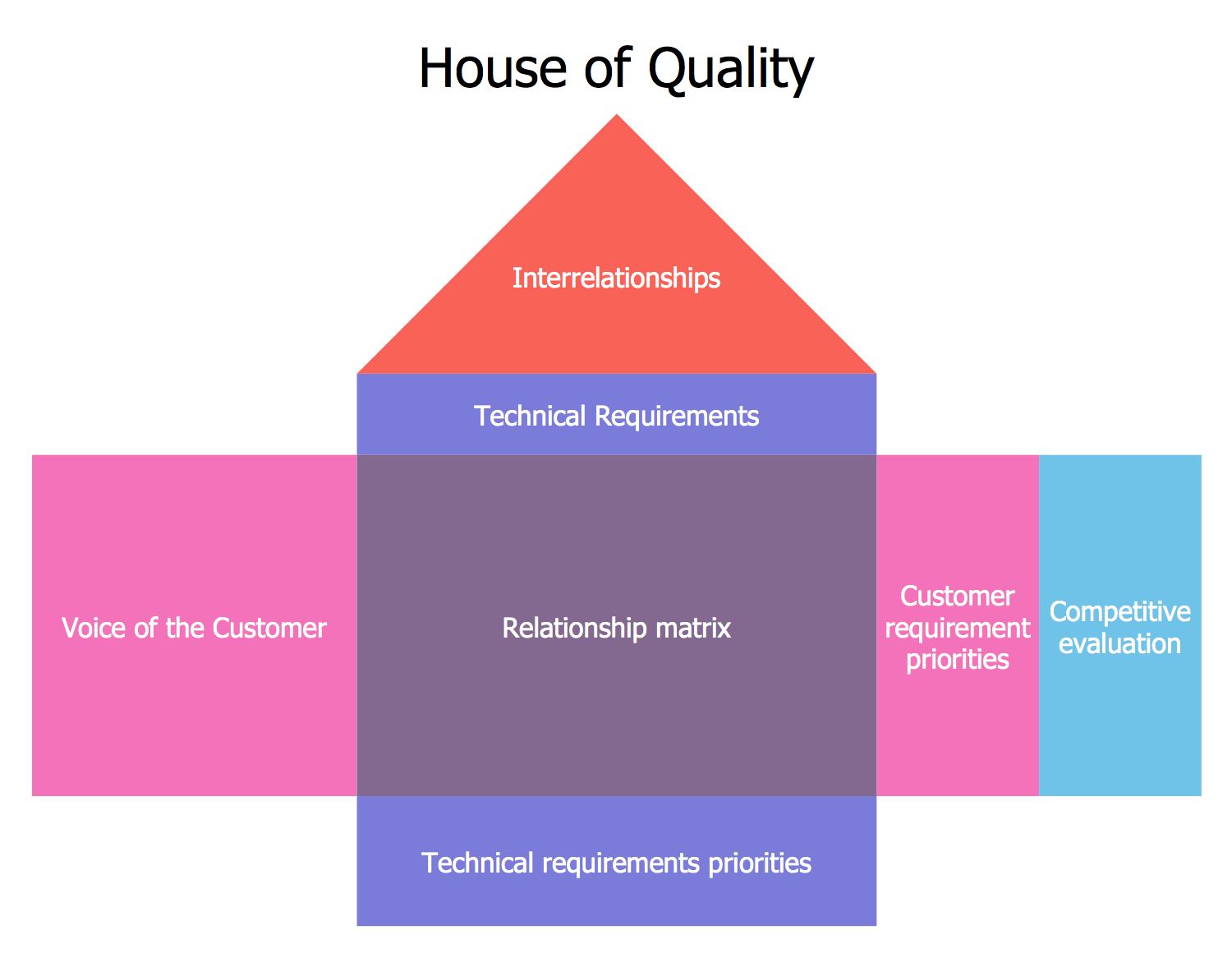

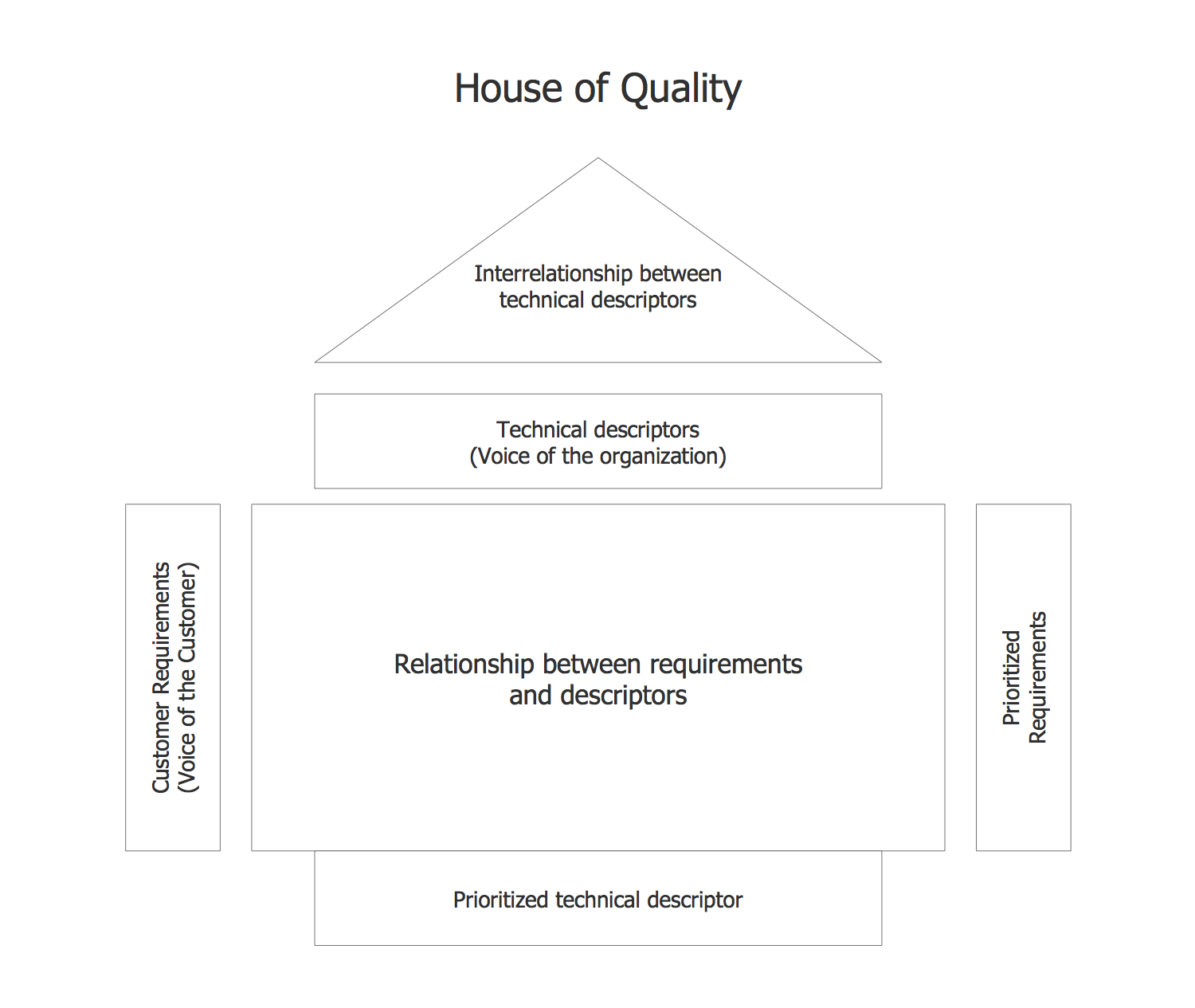

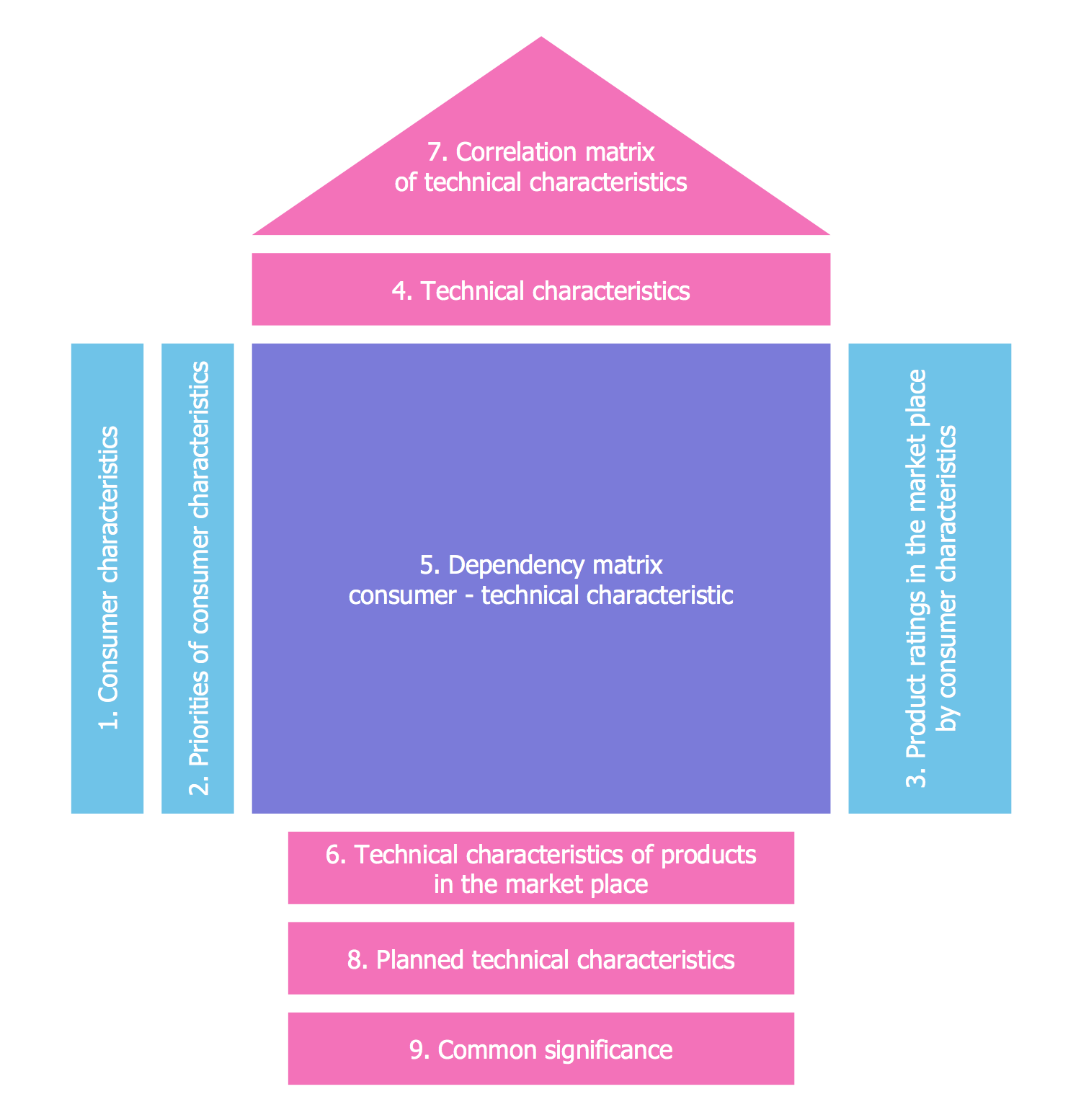

The Quality function deployment (QFD) method is based on the belief that to be successful the products need to be designed obligatory with taking into account the customers’ desires and customers' tastes, only in this case will be created the really best product, relevant and demanded, which the customers want to buy and buy with pleasure. The QFD is a flexible method of decision-making, which helps the companies to focus on the most important characteristics of a new or existing product or service. In result of applying the QFD methodology the matrix is constructed, named House of quality (HOQ) according to its shape, which contains the information about customer desires and requirements received with the help of marketing research, and corresponding engineering targets and requirements formed on their base and imposed for the manufactured product. Typically, the House of quality matrix includes six major components: customer requirements, technical requirements, the planning matrix, the interrelationship matrix, the technical correlation matrix, the technical priorities/benchmarks and targets section.

House of Quality solution extends the ConceptDraw DIAGRAM software with powerful drawing tools, numerous specific samples and examples, and set of vector design elements of House of Quality shapes and symbols, which will help you in application the Quality function deployment (QFD) methodology and in easy creation the House of Quality Matrices intended for satisfaction the consumers' desires and requirements, for representing them in a visual way and then transformation into the targets and technical requirements to be followed for development the best products.

-

Install this solution Free -

What I need to get started -

Solution Requirements - This solution requires the following products to be installed:

ConceptDraw DIAGRAM v18 - This solution requires the following products to be installed:

-

Compatibility - Sonoma (14), Sonoma (15)

MS Windows 10, 11 - Sonoma (14), Sonoma (15)

-

Support for this Solution -

Helpdesk

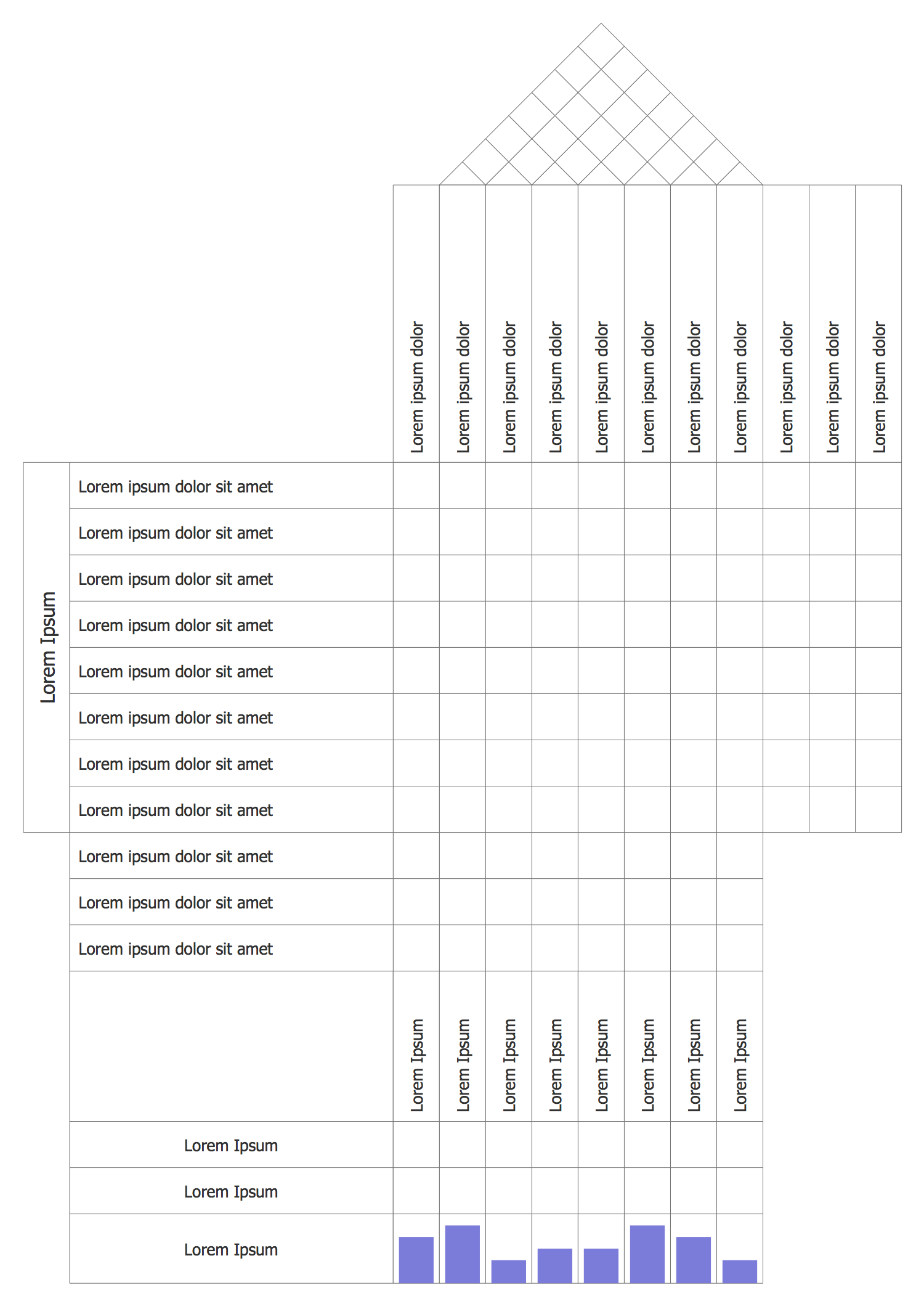

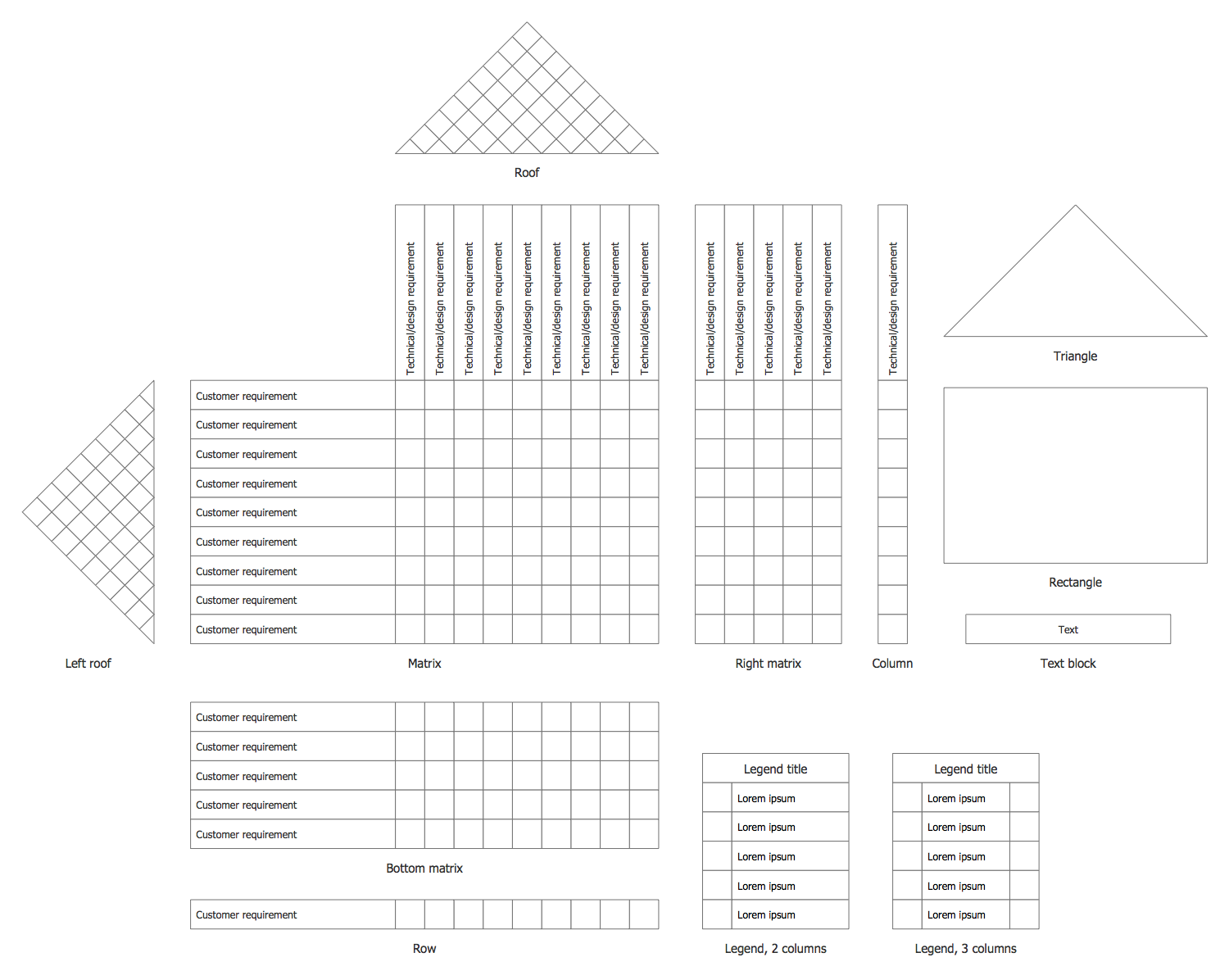

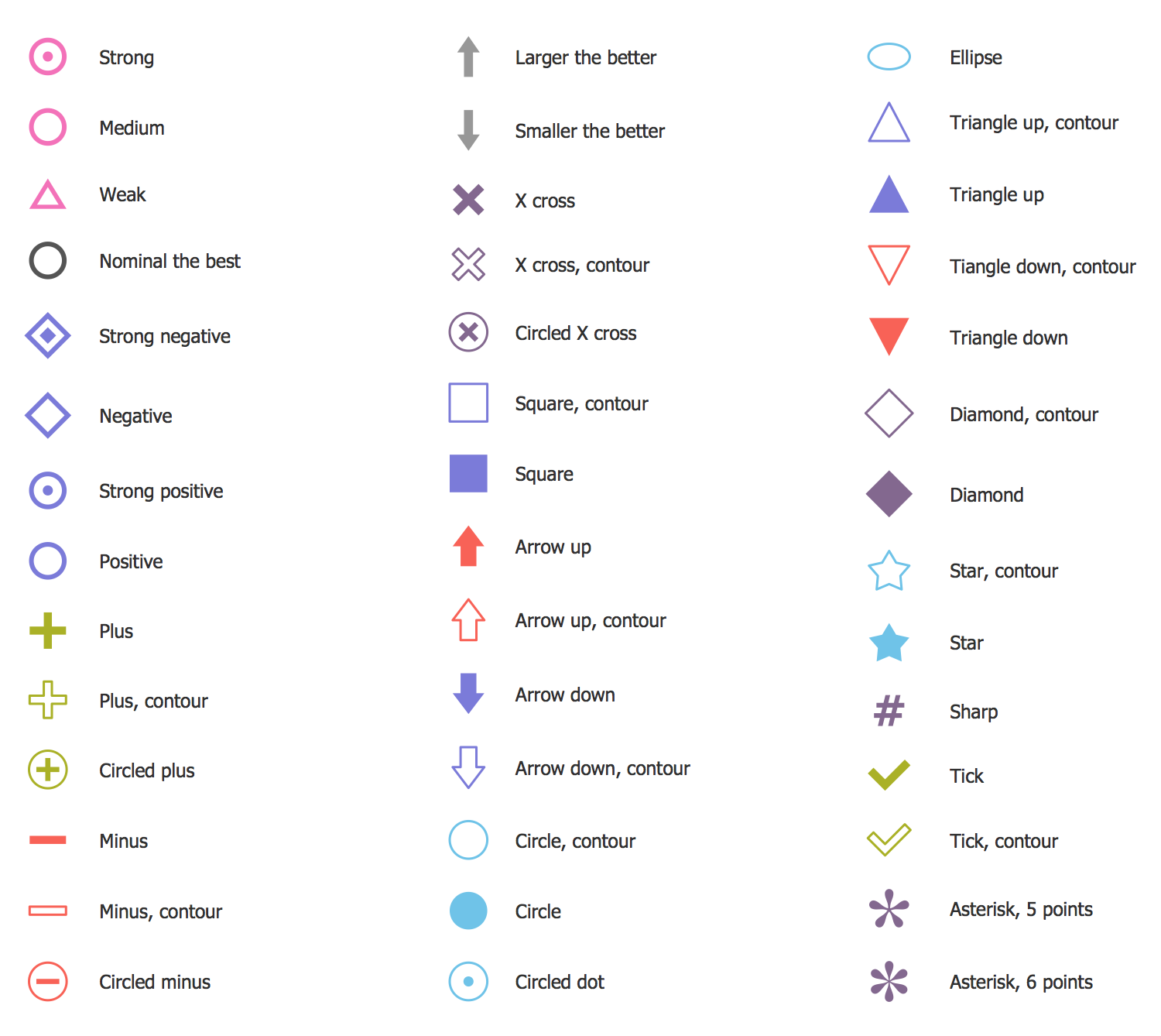

There are 2 libraries containing 54 vector graphics stencils for House of Quality solution.

Design Elements — House of Quality Shapes

Design Elements — House of Quality Symbols

Related News:

Examples

There are a few samples that you see on this page which were created in the ConceptDraw DIAGRAM application by using the House of Quality solution. Some of the solution's capabilities as well as the professional results which you can achieve are all demonstrated here on this page.

All source documents are vector graphic documents which are always available for modifying, reviewing and/or converting to many different formats, such as MS PowerPoint, PDF file, MS Visio, and many other graphic ones from the ConceptDraw Solution Park or ConceptDraw STORE. The House of Quality solution is available to all ConceptDraw DIAGRAM users to get installed and used while working in the ConceptDraw DIAGRAM diagramming and drawing software.

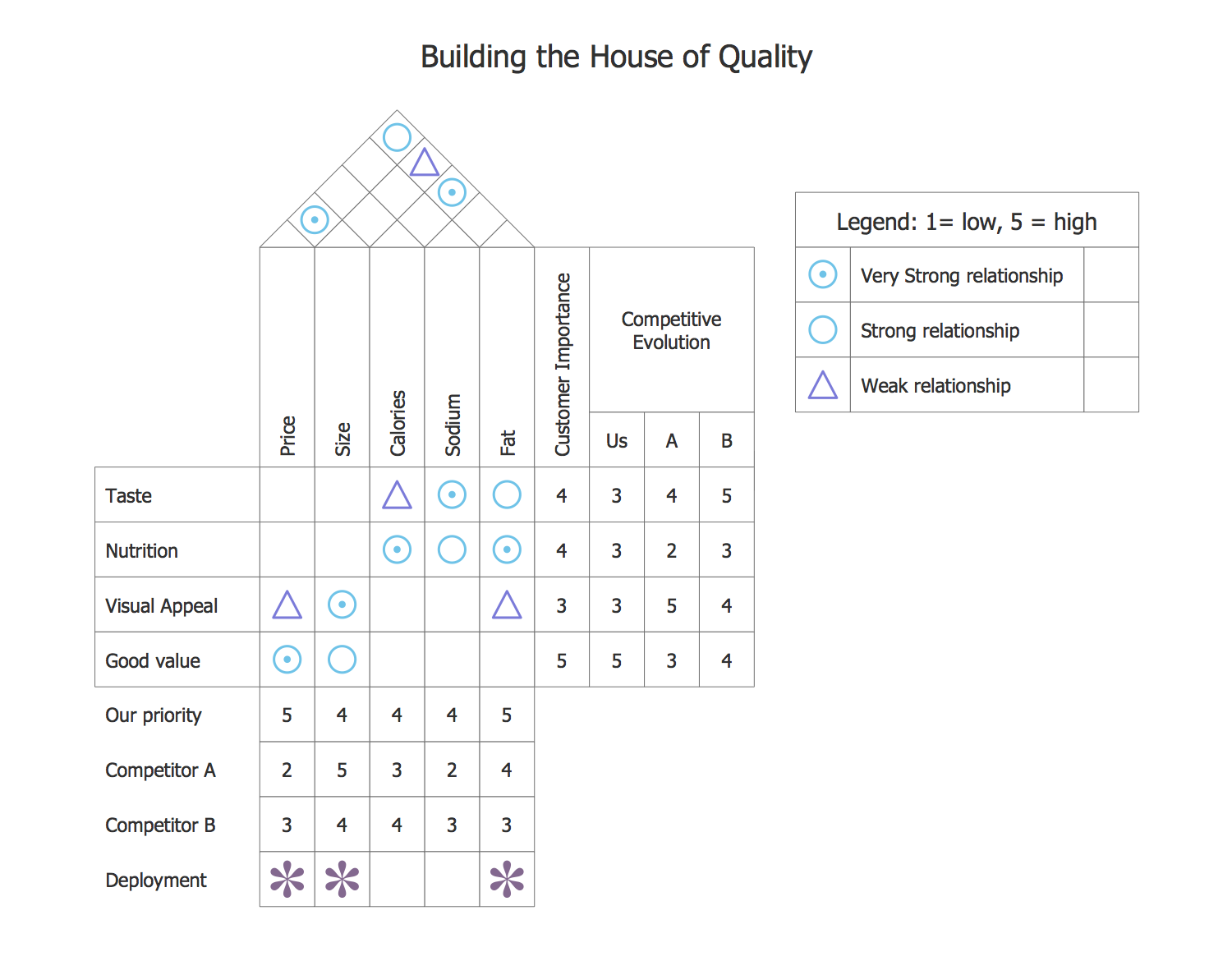

Example 1: Building the House of Quality

This diagram was created in ConceptDraw DIAGRAM using the combination of libraries from the House of Quality Solution. An experienced user spent 5 minutes creating this sample.

This sample diagram illustrates the building of House of quality matrix. The House of quality matrix is a widely used and the most recognized form of the Quality Function Deployment method. In its base lies the opinion that the products must be designed taking into account the customers' desires and tastes. This diagram includes figures along with characters which meanings are described in detail in the legend. There used symbols indicating very strong relationship, strong relationship and weak relationship. As for the process of building the House of Quality matrix - the best way is to use the ConceptDraw DIAGRAM software extended with new House of Quality solution, which makes this process the easiest and requiring no efforts and drawing abilities. All you need is offered by solution libraries – the objects for composing the House of Quality Matrix and common house of quality symbols.

Example 2: House of Quality

This diagram was created in ConceptDraw DIAGRAM using the combination of libraries from the House of Quality Solution. An experienced user spent 5 minutes creating this sample.

This sample represents the House of quality matrix diagram. The matrix format is the base of Quality Function Deployment (QFD) method, which lets to allocate visually the issues vital for the process of planning new product or service, lets to transform the customer requirements defined during the holding of marketing researches and benchmarking of data, to the defined set of engineering targets for designing a required product. The common view of the House of quality matrix is represented on this sample. This House of quality matrix is composed from the following set of components: voice of the customer, interrelationships, technical requirements, relationship matrix, technical requirements priorities, customer requirement priorities, and competitive evaluation. The division of diagram’s areas with different colors that you can see on this diagram, is a successful and often used way of visual representation the information for gaining an advantage and attraction attention exactly to your diagram.

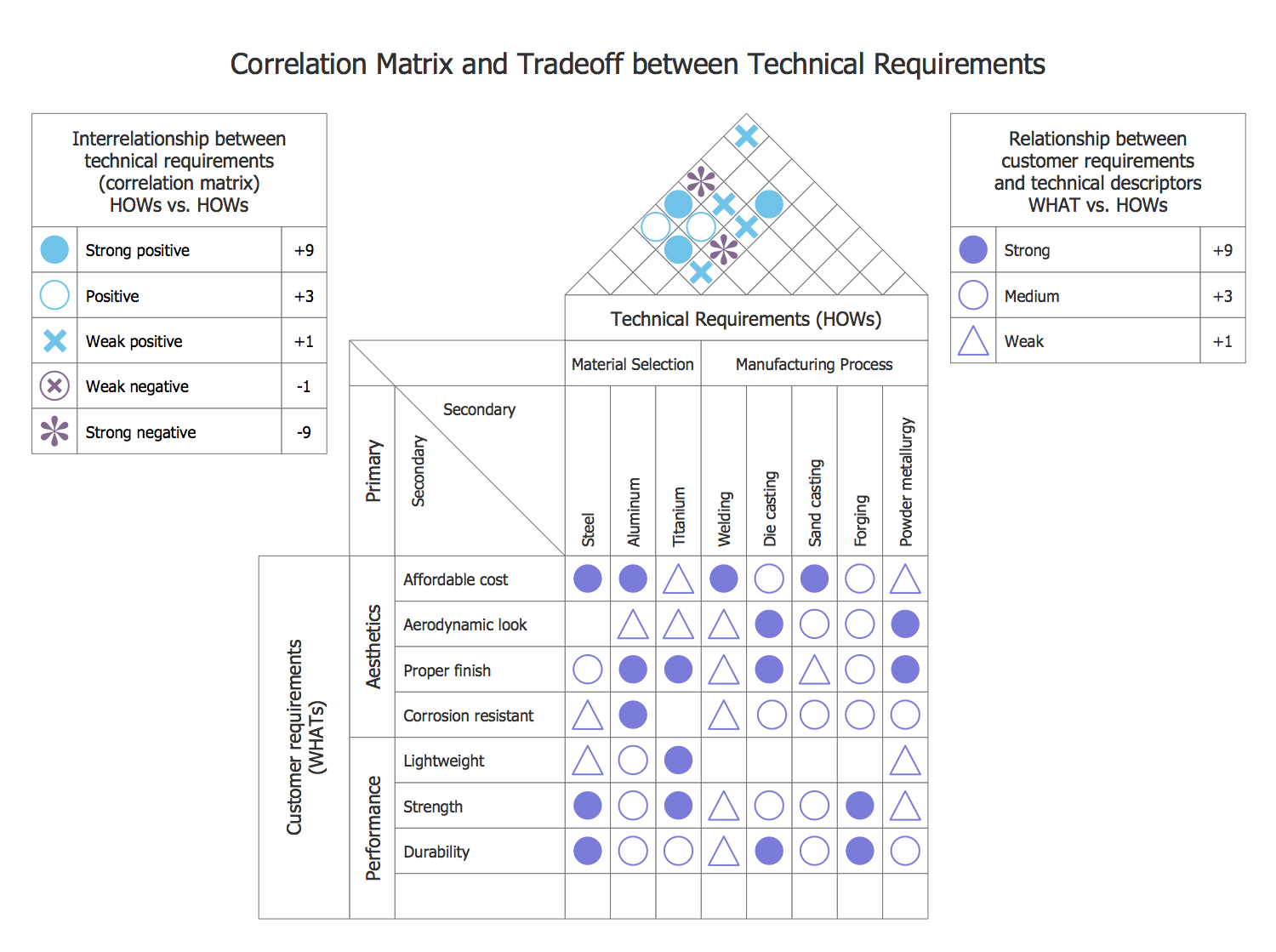

Example 3: House of Quality Correlation Matrix

This diagram was created in ConceptDraw DIAGRAM using the combination of libraries from the House of Quality Solution. An experienced user spent 10 minutes creating this sample.

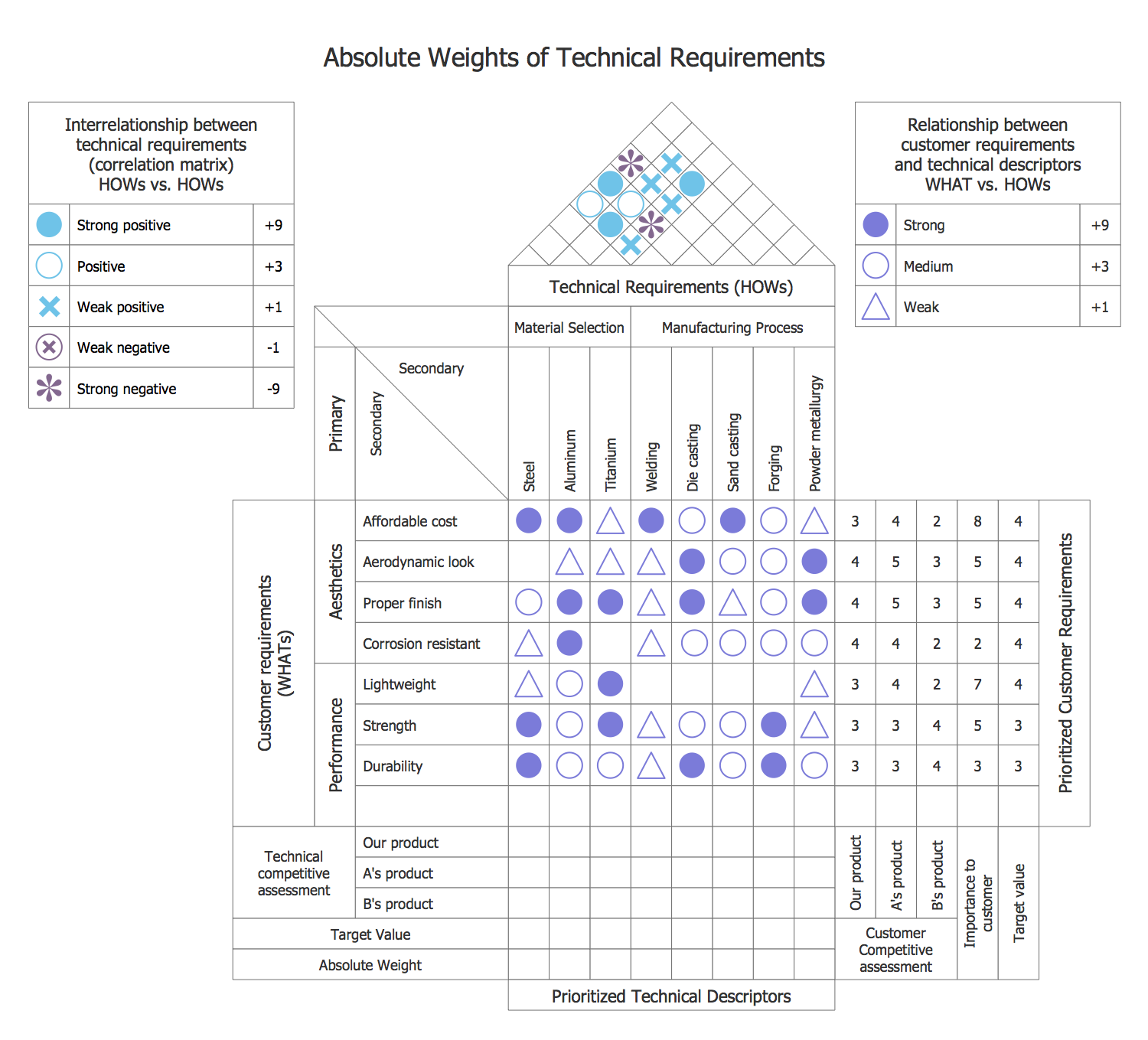

This House of Quality sample diagram illustrates the Correlation matrix and tradeoff between technical requirements. The great value has the evaluation of filling the cells after the matrix construction. Each empty row or column has certain meaning. So, the empty column indicates that the technical requirements are unnecessary and don't address any customer's voice. In its turn, the empty row specifies the fact that the customer's voice isn't addressed by any technical descriptors. The roof of this House of quality is arranged in a form of correlation matrix and is a good way to identify the interrelationships between the technical descriptors. The symbols used on this diagram depict the strength of interrelationships, among them are: the solid circle that represents a strong positive relationship, the circle that depicts a positive relationship, the X symbol that represents a weak positive relationship, the X symbol in circle that depicts a weak negative relationship, and the asterisk that represents a strong negative relationship.

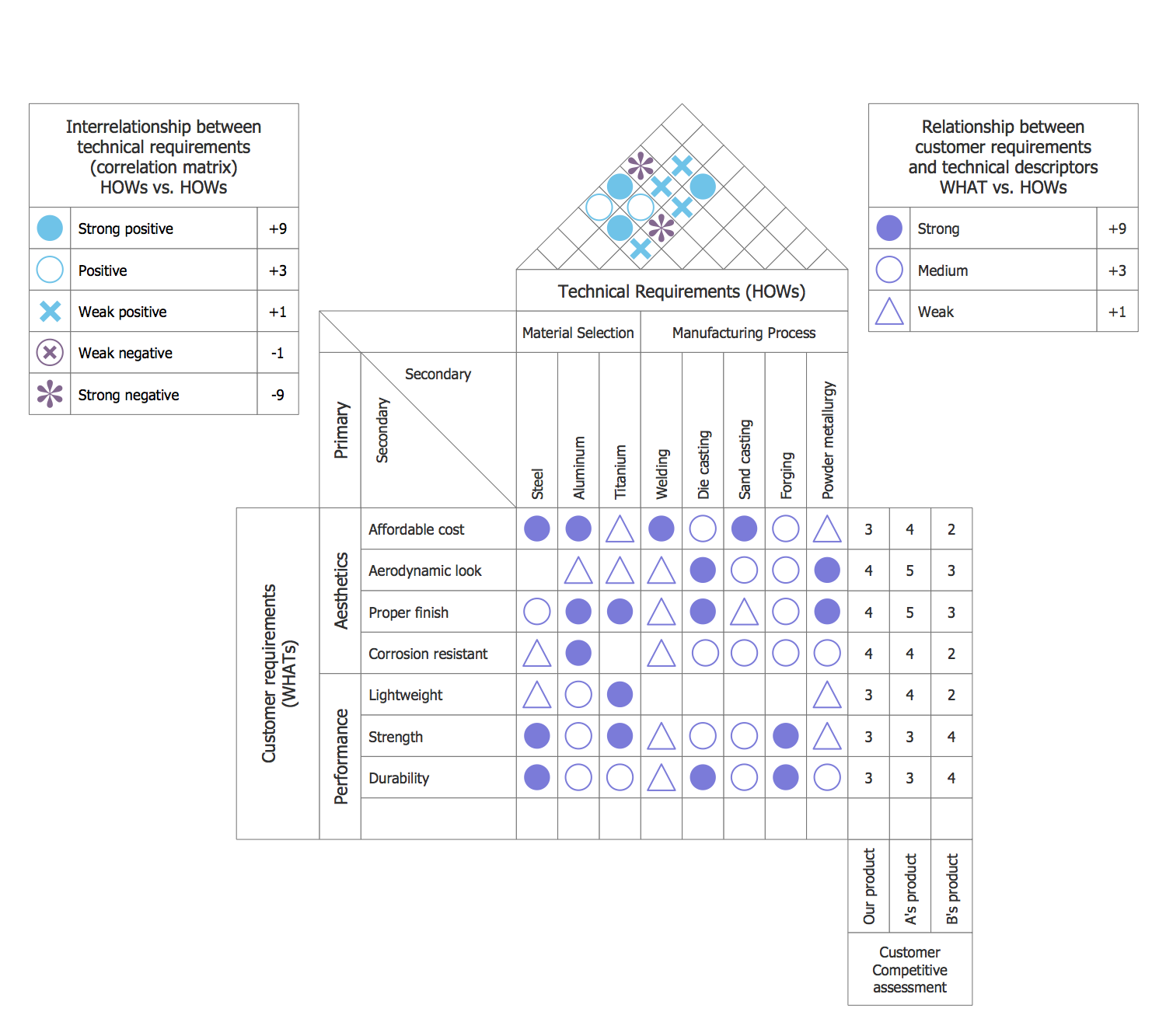

Example 4: House of Quality Customer’s Competitive Assessment

This diagram was created in ConceptDraw DIAGRAM using the combination of libraries from the House of Quality Solution. An experienced user spent 10 minutes creating this sample.

This House of quality example depicts the competitive assessment of voice of the customer (VOC), which is the good way to determine how the customer voice was met in comparing with the competitors, as well as to identify the areas of improvement the future design. The table depicting the customer’s competitive assessment demonstrates the comparison of the competitive products with current organization product status on a specific voice of the customer. Pay please attention on the diagram's composition, you can see the columns representing the technical requirements (HOWs), the rows representing the customer requirements (WHATs), and the block of customer competitive assessment columns with values corresponding to the customer requirements and placed at the right side of this House of quality matrix. The used values of competitive evaluation from 1 to 5 indicate the rating from the worst to the best. Description of two sets of symbols used in this matrix is presented in the separated legend tables.

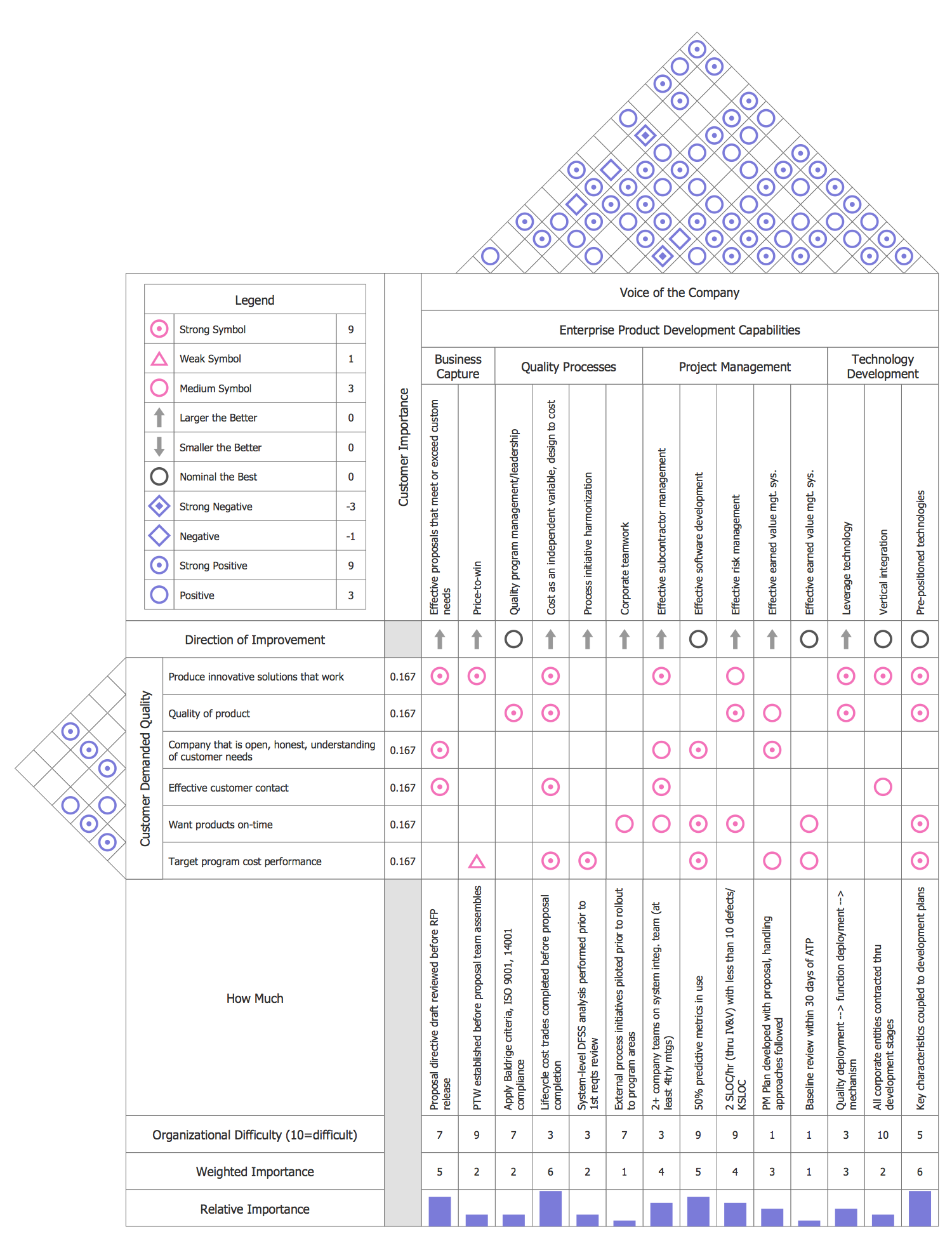

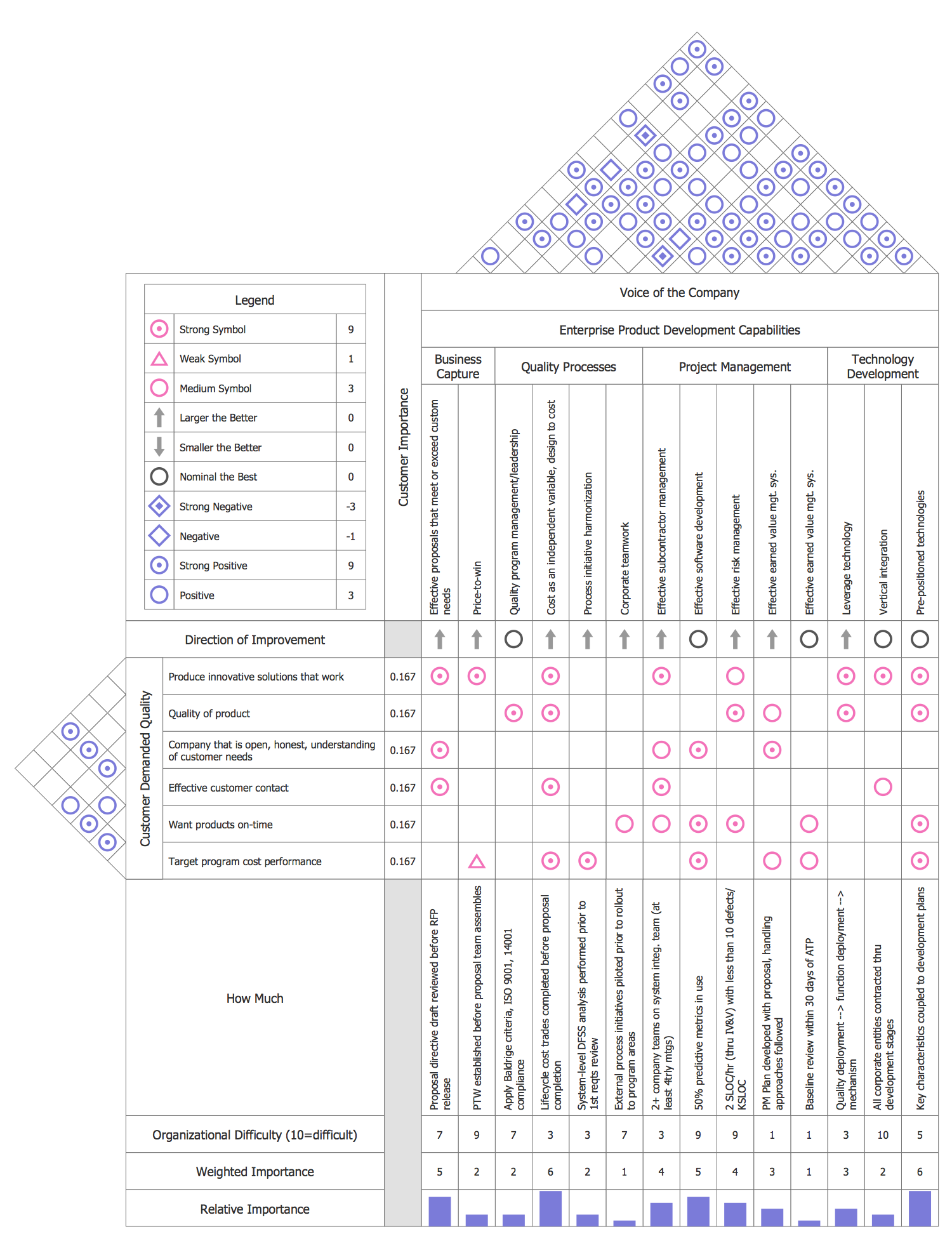

Example 5: House of Quality Diagram

This diagram was created in ConceptDraw DIAGRAM using the combination of libraries from the House of Quality Solution. An experienced user spent 20 minutes creating this sample.

This sample diagram demonstrates the House of quality (HOQ) matrix depicting the enterprise product development processes. The House of Quality is a diagram looks like a house and applied for defining the relationships between customer desires and the capabilities of company and product in particular. It lets to represent in a compact form the information about varied characteristics of product and to track their impact on the taken technical solutions. The roof of the House of quality represents the information about the correlation between characteristics. The central part of the House of quality is a table, which columns correspond to the product technical characteristics and the rows to the consumer ones. At the table cells are contained the levels of dependency. At the left side of this diagram, you can also find the legend explaining the meanings of used symbols. All objects used for construction this sample are taken ready-made from the libraries of ConceptDraw’s House of Quality solution.

Example 6: House of Quality (HOQ)

This diagram was created in ConceptDraw DIAGRAM using the combination of libraries from the House of Quality Solution. An experienced user spent 5 minutes creating this sample.

This sample diagram illustrates the basic structure of the House of quality (HOQ), which main goal is to determine the prioritized technical requirements. All house’s parts are accurately structured and represented. The roof of the house reflects the interrelationships between the independent technical requirements or technical descriptors, in this part is achieved the tradeoff between conflicting and similar technical requirements. The house's ceiling contains the technical descriptors or voice of the organization. The central part of the house describes the relationships between the customer requirements and technical requirements, the customer requirements or customer voices are transferred into the engineering requirements or technical descriptors. If we talk about the outside walls of the house, the left wall represents the customer requirements (voice of the customer) and the right wall depicts their priorities (prioritized requirements) that were obtained in result of customers' survey. Finally, at the bottom of diagram (house's floor) is represented the prioritized technical descriptor.

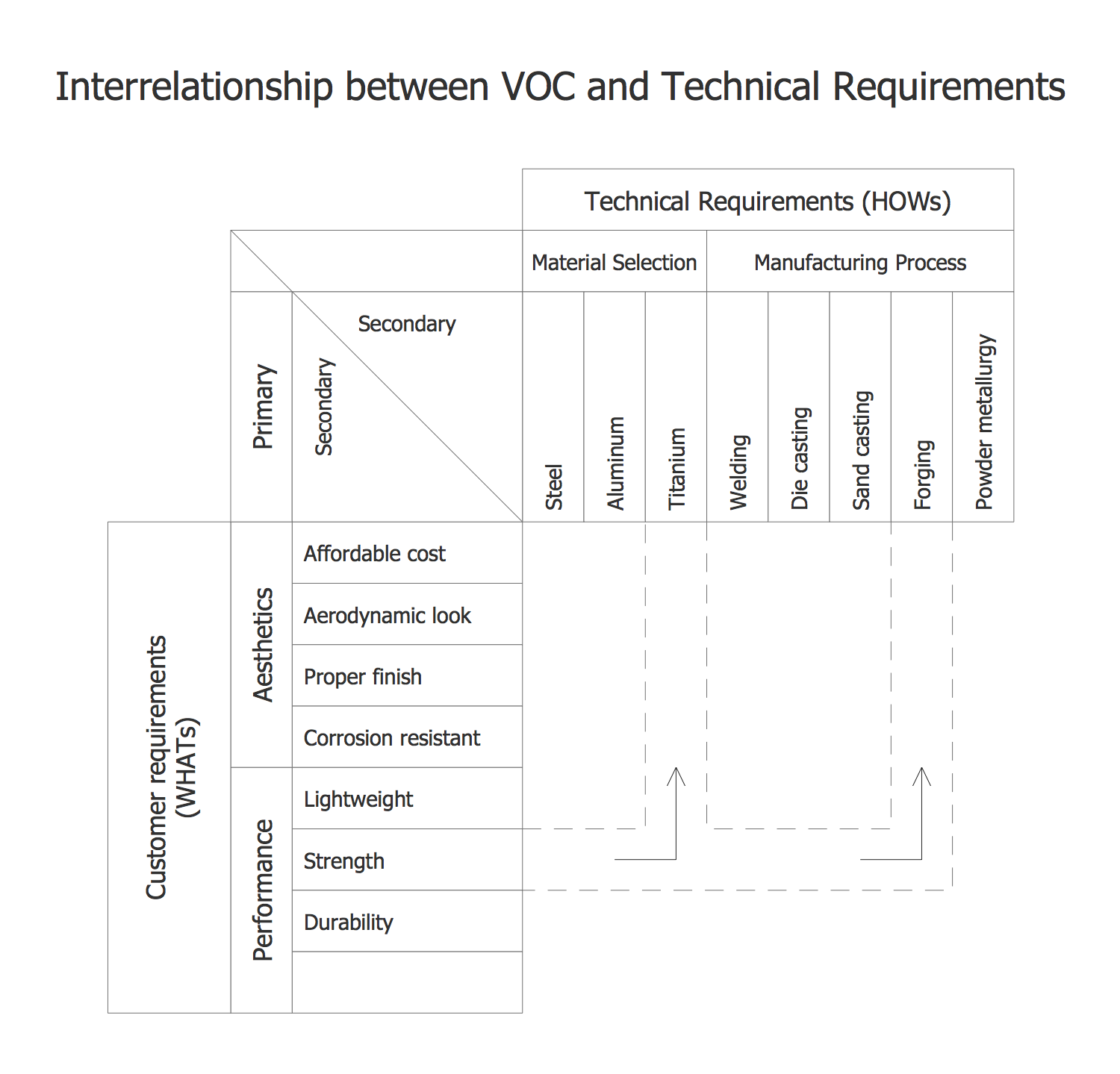

Example 7: House of Quality Interrelationship Matrix

This diagram was created in ConceptDraw DIAGRAM using the combination of libraries from the House of Quality Solution. An experienced user spent 5 minutes creating this sample.

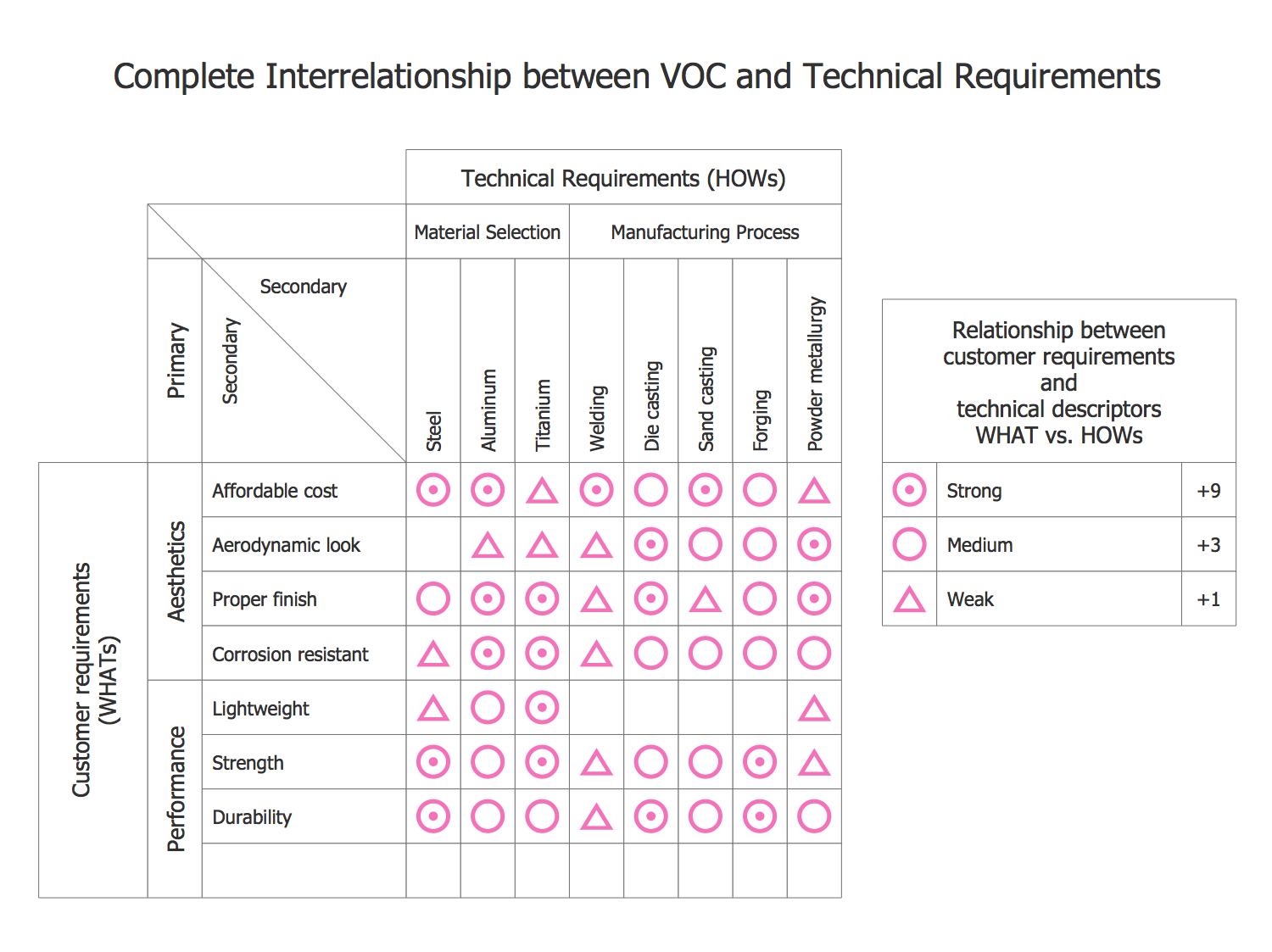

This House of quality sample shows the interrelationship matrix. One of the steps in the process of building the House of quality matrix is comparison the VOC (voice of the customer) with technical characteristics and also determination their interrelationships. This sample visually reflects the complete interrelationships between VOC and technical requirements. Typically, for representation the nature of relationship between customer requirements (WHATs) and technical descriptors or technical requirements (HOWs) are used the common symbols. The relationships between customer requirements and technical descriptors (WHATs vs. HOWs) can be strong, medium or weak. According to the offered legend, the strong relationship (scored as +9) is designated by solid circle, the medium relationship (scored as +3) is marked by single circle, and weak relationship (scored as +1) is represented by triangle. The cell is left empty in case of absence the relationship between VOC and technical characteristics, or when existing relationship is insignificant.

Example 8: House of Quality of Buses

This diagram was created in ConceptDraw DIAGRAM using the combination of libraries from the House of Quality Solution. An experienced user spent 10 minutes creating this sample.

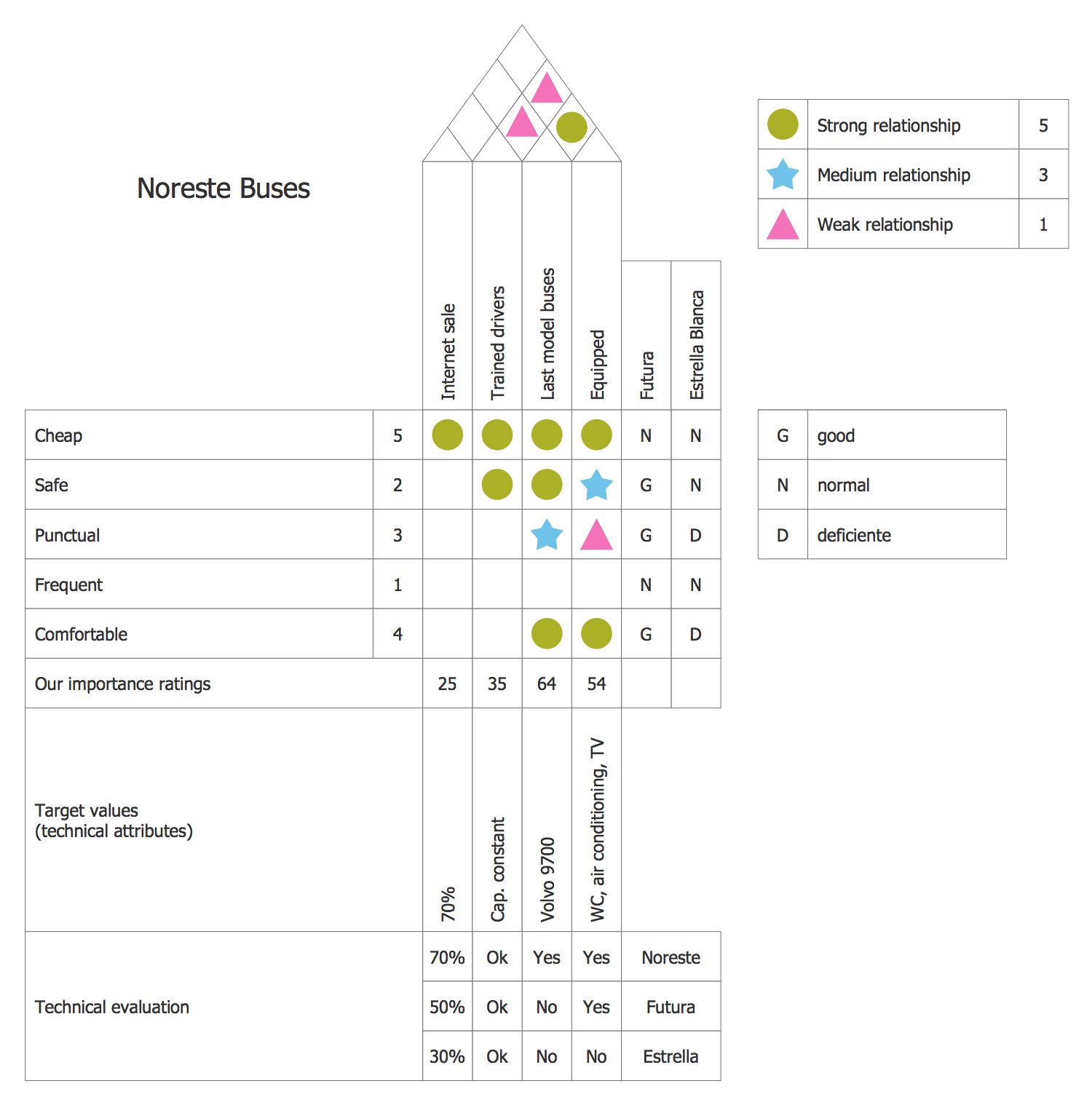

This sample diagram demonstrates the House of quality matrix constructed in ConceptDraw DIAGRAM specially to classify and represent the information and data according to the buses. The main aim of construction the House of quality as a part of Quality function deployment method, is to identify the customers’ desires, to classify them according to the importance, to recognize the engineering characteristics that may be relevant to these desires, then to assign the objectives and to set priorities for the system requirements. This process can be applied at any level of designing the product. This House of quality matrix contains in cells numerical data, symbols and letter symbols. Designed using the tools of House of Quality solution from the Quality area of ConceptDraw Solution Park, this sample is attractive due to the use of bright symbols and can be used as a perfect base for creating the similar House of quality matrices.

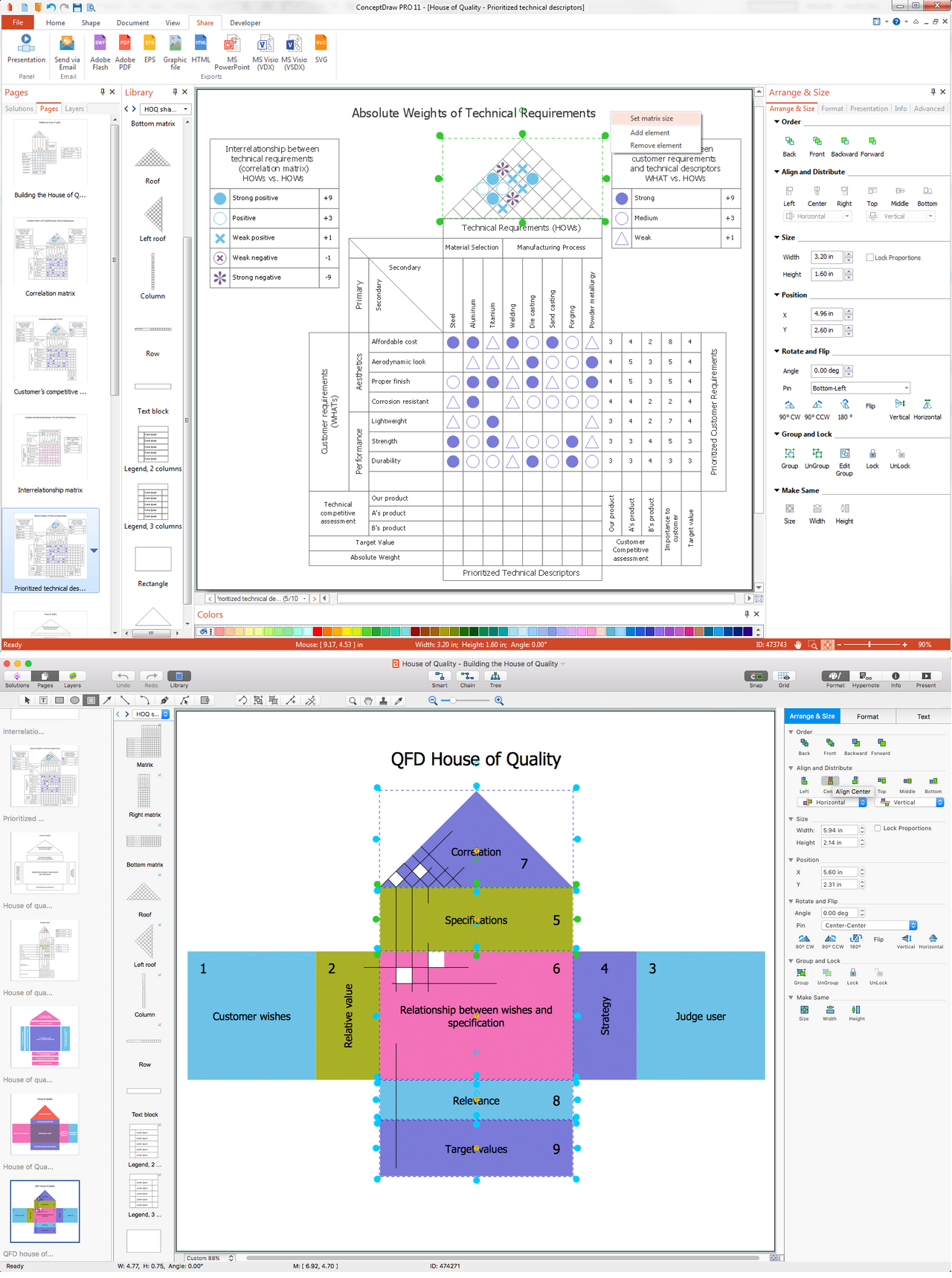

Example 9: House of Quality Prioritized Technical Descriptors

This diagram was created in ConceptDraw DIAGRAM using the combination of libraries from the House of Quality Solution. An experienced user spent 15 minutes creating this sample.

This House of quality diagram sample illustrates the absolute weights of technical requirements and prioritized technical descriptors. The absolute weights for the technical descriptors are calculated as the scalar products of values from the corresponding columns in relationship matrix and the values from the importance to customer column. After the calculation, the values of absolute weights are fixed at the last row of the House of quality diagram and then analyzed, because the greater values of absolute weights indicate at the higher importance of corresponding technical descriptors to address VOC. Pay also attention to the block of rows of the technical competitive assessment, which is placed under the relationship matrix and corresponds to each technical descriptor in the house of quality. To indicate the rating from the worst to the best for the technical competitive assessment, there are used the values from 1 through 5, just like for the prioritized customer requirements.

Example 10: House of Quality Scheme

This diagram was created in ConceptDraw DIAGRAM using the combination of libraries from the House of Quality Solution. An experienced user spent 5 minutes creating this sample.

This sample represents the scheme depicting the main steps of sequential application the Quality function deployment (QFD) methodology for construction the House of quality (HOQ) matrix. The Quality Function Deployment (QFD) is a well known methodology of systematic and structured conversion the consumers’ needs into requirements for quality of product, service, or process. This methodology effectively contribute for better understanding the consumers in a process of designing, development and improvement products, it helps to ensure that the "voice of the customer" was heard when developing products and respective manufacturing operations. The Quality function deployment process starts with definition the list of goals or objectives, which are named WHATs and reflect the customers' needs and expectations in a particular product. Then this list is extended and specified with secondary customer requirements, and there are defined the engineering characteristics (HOW’s), which will affect the customer perception (VOC) and will satisfy one or more listed customer requirements.

Example 11: House of Quality VOC vs Technical Requirements

This diagram was created in ConceptDraw DIAGRAM using the combination of libraries from the House of Quality Solution. An experienced user spent 5 minutes creating this sample.

This House of quality sample diagram shows the VOC (voice of the customer) vs. technical requirements. According to the Quality function deployment methodology the customer needs and expectations are represented as the customer requirements (WHATs). The implementation of customer requirements can be executed only when they are transformed into the technical characteristics or technical requirements (HOW’s). So, in terms of QFD need to be developed the set of engineering characteristics satisfying the customer requirements and customer perception, i.e. the VOC. These technical characteristics are expressed in terms of technical language and specifications. This House of quality matrix is a simple scheme, which can be easily extended during the QFD process and transformed in a complete House of quality matrix with the help of tools of House of Quality solution from the Quality area of ConceptDraw DIAGRAM Solution Park. The construction of House of quality diagram for a specific product will take only few minutes in ConceptDraw DIAGRAM

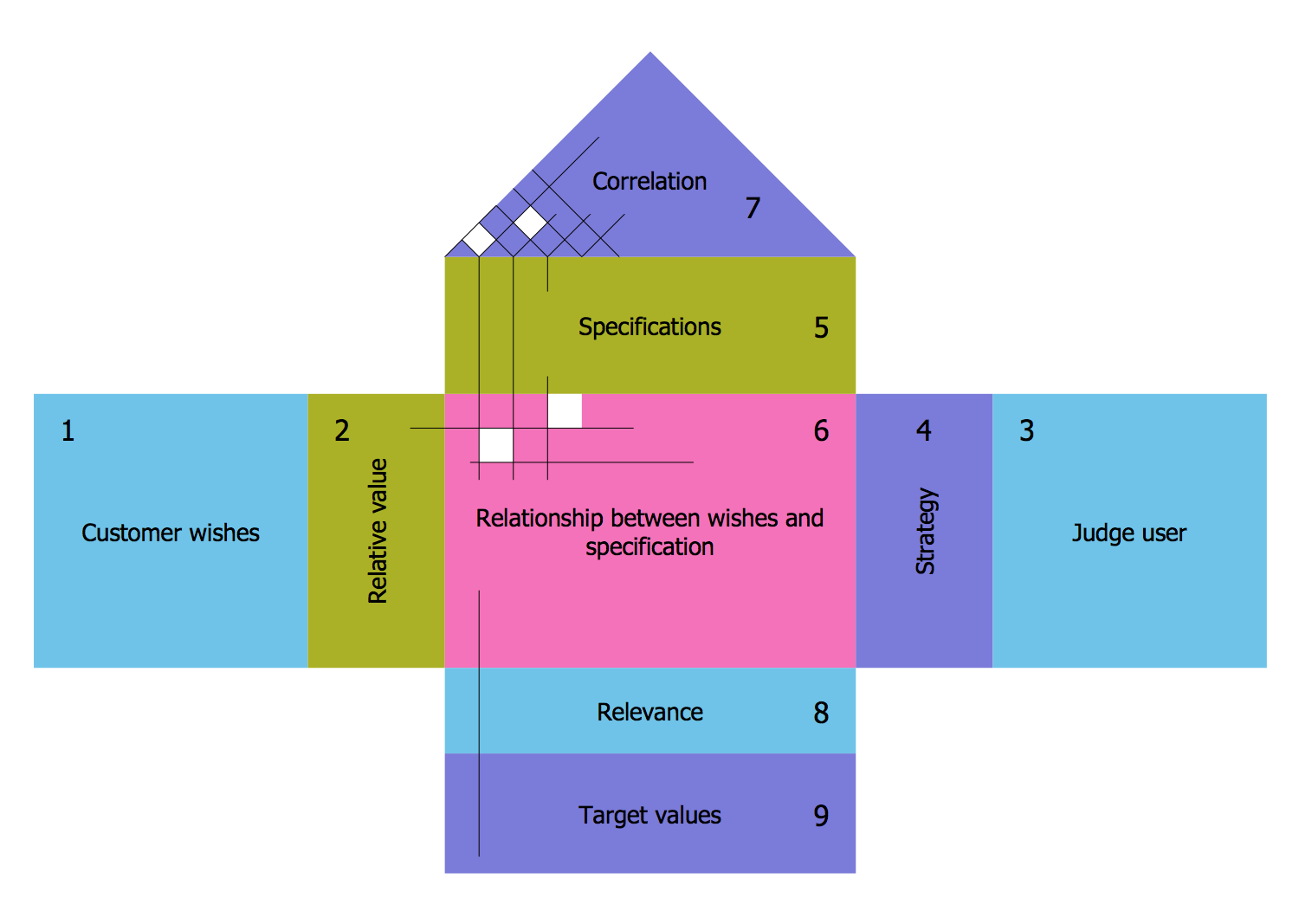

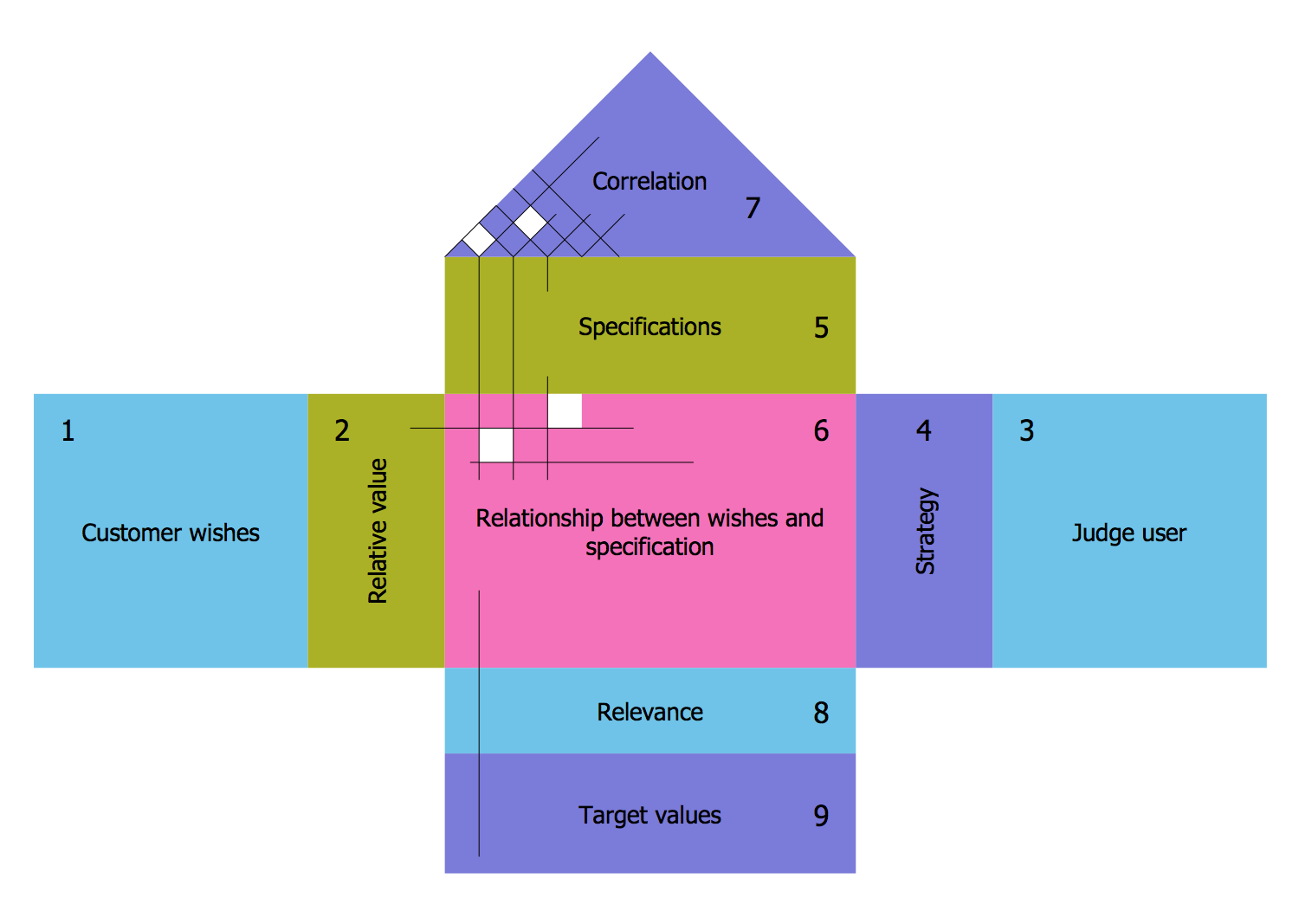

Example 12: QFD House of Quality

This diagram was created in ConceptDraw DIAGRAM using the combination of libraries from the House of Quality Solution. An experienced user spent 5 minutes creating this sample.

This sample diagram illustrates the QFD House of Quality matrix. The Quality function deployment is a methodology helpful in many questions, such as planning new products, designing product requirements, determining the process characteristics, controlling the manufacturing process, documenting the product specifications, etc. The House of quality is a unite of few deployment hierarchies and tables, this set includes the Demanded Quality Hierarchy, Relationships matrix, Quality Characteristics Hierarchy, Quality Planning Table, Design Planning Table. The main goal of the House of quality matrix is to formulate the correct technical characteristics for a specific product, which are based on the voice of the customer (VOC), i.e. the customer needs, customer requirements and customer wishes. The stages of construction the House of quality matrix are enumerated and visually separated by different colors, briefly these steps are named as customer wishes, relative value, judge user, strategy, specifications, relationship between wishes and specification, specifications, correlation, relevance, and target values.

Inside

What I Need to Get Started

Both ConceptDraw DIAGRAM diagramming and drawing software and the House of Quality solution can help creating the quality control diagrams you need. The House of Quality solution can be found in the Quality Management area of ConceptDraw STORE application that can be downloaded from this site. Make sure that both ConceptDraw DIAGRAM and ConceptDraw STORE applications are installed on your computer before you get started.

How to install

After ConceptDraw STORE and ConceptDraw DIAGRAM are downloaded and installed, you can install the House of Quality solution from the ConceptDraw STORE.

Start using

To make sure that you are doing it all right, use the pre-designed symbols from the stencil libraries from the solution to make your drawings look smart and professional. Also, the pre-made examples from this solution can be used as drafts so your own drawings can be based on them. Using the samples, you can always change their structures, colors and data.

House of Quality (HOQ) diagrams

QFD is an abbreviation of the Quality Function Deployment. It is one of the methods that was developed in 1966 in Japan being used for helping to transform the so-called “VOC” (voice of the customer) into some particular customer-driven engineering characteristics for some definite product. VOC is a term that is widely used both in information technology and in business for describing the in-depth process of capturing some customer's preferences, aversions and expectations. The Quality function deployment can be also described as a method for transforming the qualitative user demands into some quantitative parameters, to deploy the methods for achieving the design quality into the component parts and subsystems, as well as to some specific elements of the manufacturing process and to deploy the functions forming quality.

Pic. 1. House of Quality Diagram

The House of Quality (HOQ) is one of the tools used within the QFD method, that is widely used for correlating the customers’ needs to engineering specifications.

Also, you can always create any needed matrix of the product planning, decision matrices or any needed Kano model that can be useful in gaining a general understanding of your customers’ needs, being a tool for both collecting and systematizing VOC. This Kano model can be also known as a theory of customer satisfaction and product development that was developed by Professor Noriaki Kano in the 1980s classifying all the customer preferences into five general categories, involving two dimensions (Achievement and Satisfaction). There are three levels of customer expectations that can be always isolated, being identified as “expected”, “normal” and “exciting”.

Both in engineering and business, the so-called “new product development”, or NPD, is also widely used covering the complete process of bringing some new product to the market. Any product design is a central aspect of any process of any new product development. The new product development can be also described as the transformation of some market opportunity into a product that is available for sale, which can be either tangible or intangible.

Pic. 2. QFD House of Quality

Being one of the most important aspects of any product design, the HOQ diagrams are known to be an important constituent of the QFD method. QFD is a structured method that uses the seven management and planning tools for prioritizing the previously identified customers’ expectations in a quick and effective way. There is also a solution called Seven Management and Planning Tools which can be found within the ConceptDraw STORE application.

The non-functional requirements’ analysis that can be conducted within any process optimization is meant to improve the quality of a product or service being another area of the HOQ diagrams application. The “non-functional requirement” (NFR) is simply a requirement that specifies some particular criteria that can be used for judging the operations in some system or systems.

HOQ diagrams can be also used in marketing research for comparing the competing products in order to achieve customers’ satisfaction with the quality of goods/services. “Customer satisfaction” (CS) is a measure of how services and products can be supplied by some company in order to meet their customers’ expectations. CS can be also defined as the number of customers whose reported experience with some company’s products/services or the company itself exceeding some specified satisfaction goals.

HOQ diagrams can be also applied at different stages of any product development cycle, as well as for improving the quality in product lifecycle management. The so-called “product development cycle” is also something that has to be taken into account in order to win the race with your competitors. Thus, there is a product lifecycle management (PLM) that is widely used in industry same as the product management and the quality management, being the process of managing the whole lifecycle of some product from its inception. This process goes through the stage of the manufacture and engineering design, servicing and disposing of the manufactured products. PLM is known for integrating many different people, business systems and different processes, providing some product information base for companies.

Pic. 3. QFD House of Quality solution

The new solution of the ConceptDraw STORE application developed by CS Odessa — House of Quality — allows creating the House of Quality matrices. The House of Quality solution complements ConceptDraw DIAGRAM, making it a convenient tool for making the professional HOQ and QFD diagrams, as it includes the vector stencils libraries as well as the examples of the diagrams for making it simpler and quicker to create the HOQ matrices.