"Root cause analysis (RCA) is a method of problem solving that tries to identify the root causes of faults or problems.

RCA practice tries to solve problems by attempting to identify and correct the root causes of events, as opposed to simply addressing their symptoms. Focusing correction on root causes has the goal of preventing problem recurrence. RCFA (Root Cause Failure Analysis) recognizes that complete prevention of recurrence by one corrective action is not always possible.

Conversely, there may be several effective measures (methods) that address the root causes of a problem. Thus, RCA is an iterative process and a tool of continuous improvement.

RCA is typically used as a reactive method of identifying event(s) causes, revealing problems and solving them. Analysis is done after an event has occurred. Insights in RCA may make it useful as a preemptive method. In that event, RCA can be used to forecast or predict probable events even before they occur. While one follows the other, RCA is a completely separate process to Incident Management." [Root cause analysis. Wikipedia]

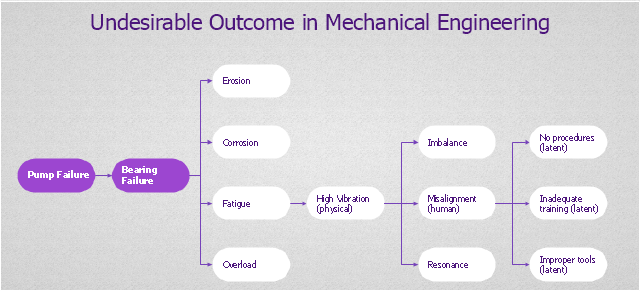

The root cause analysis (RCA) tree diagram example "Manufacturing problem solution" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the solution "Seven Management and Planning Tools" from the Management area of ConceptDraw Solution Park.

RCA practice tries to solve problems by attempting to identify and correct the root causes of events, as opposed to simply addressing their symptoms. Focusing correction on root causes has the goal of preventing problem recurrence. RCFA (Root Cause Failure Analysis) recognizes that complete prevention of recurrence by one corrective action is not always possible.

Conversely, there may be several effective measures (methods) that address the root causes of a problem. Thus, RCA is an iterative process and a tool of continuous improvement.

RCA is typically used as a reactive method of identifying event(s) causes, revealing problems and solving them. Analysis is done after an event has occurred. Insights in RCA may make it useful as a preemptive method. In that event, RCA can be used to forecast or predict probable events even before they occur. While one follows the other, RCA is a completely separate process to Incident Management." [Root cause analysis. Wikipedia]

The root cause analysis (RCA) tree diagram example "Manufacturing problem solution" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the solution "Seven Management and Planning Tools" from the Management area of ConceptDraw Solution Park.

Seven Management and Planning Tools

Seven Management and Planning Tools

Seven Management and Planning Tools solution extends ConceptDraw PRO and ConceptDraw MINDMAP with features, templates, samples and libraries of vector stencils for drawing management mind maps and diagrams.

- Flowchart Problems And Solutions Examples

- Problem Solution Map Examples

- Fishbone Diagram Problem Solving | Using Fishbone Diagrams for ...

- PERT chart - Sale problem solution | Sales Process Flowchart ...

- Venn Diagram Examples for Problem Solving. Environmental Social ...

- Block diagram - Total solution process | Venn Diagram Examples for ...

- Chart Showing The Problem And Solution In Engineering

- Venn Diagram Examples for Problem Solving. Computer Science ...

- Example Of Chart That Showing The Engineering Solution To A

- Fishbone Diagram Problem Solving | Using Fishbone Diagrams for ...

- Solution Tree

- Flowchart Problems And Solution

- Flowchart Problem And Solution

- 3 Circle Venn Diagram Problems And Solutions

- Venn Diagram Examples for Problem Solving. Computer Science ...

- Problem Solution Sample Templates

- Problem And Solution Example

- Fishbone Diagram Problem Solving | Using Fishbone Diagrams for ...

- Quality Problems Examples