"Value Stream Mapping (VSM):

– Special type of flow chart that uses symbols known as "the language of Lean" to depict and improve the flow of inventory information. ...

Value Stream Mapping ...

Provide optimum value to the customer through a complete value creation process with minimum waste in:

– Design (concept to customer);

– Design (concept to customer);

– Build (order to delivery);

– Sustain (in-use through life cycle to service)." [courses.washington.edu/ ie337/ Value_ Stream_ Mapping.pdf]

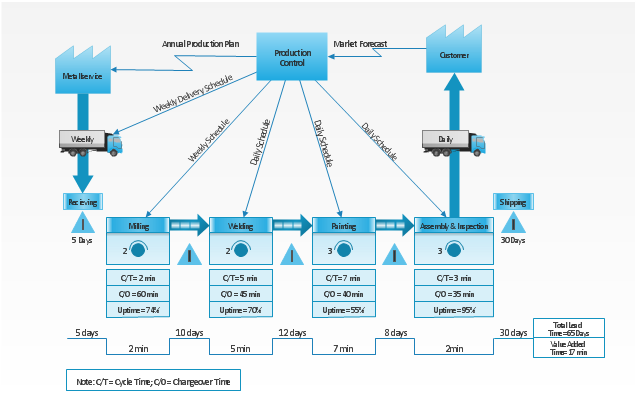

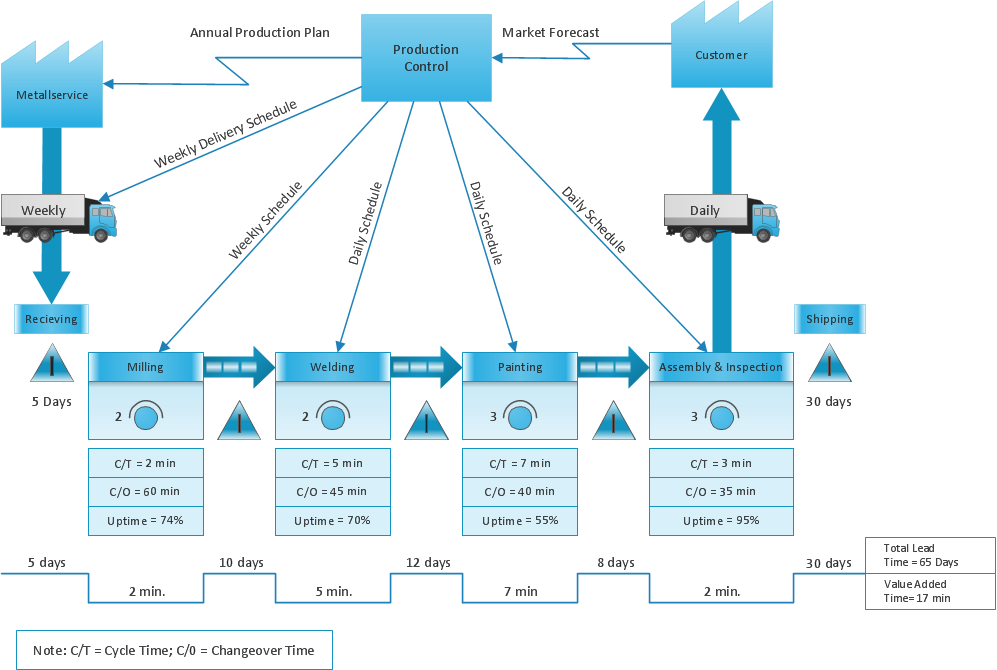

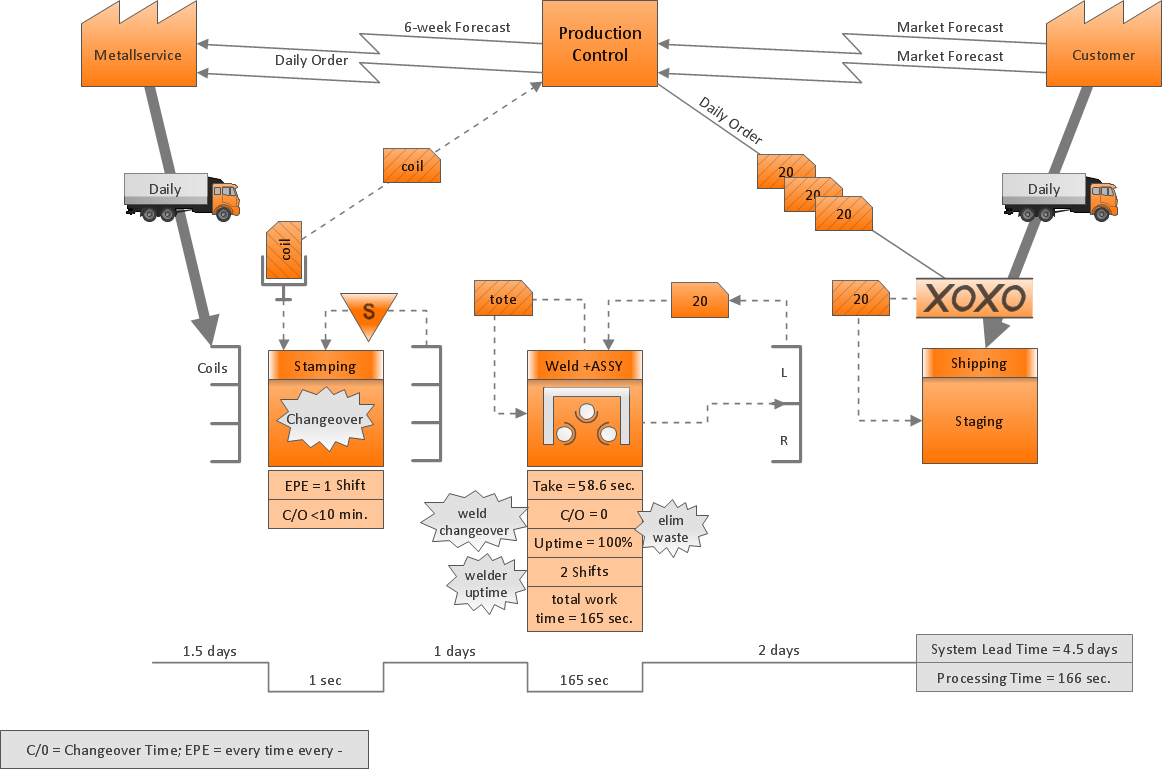

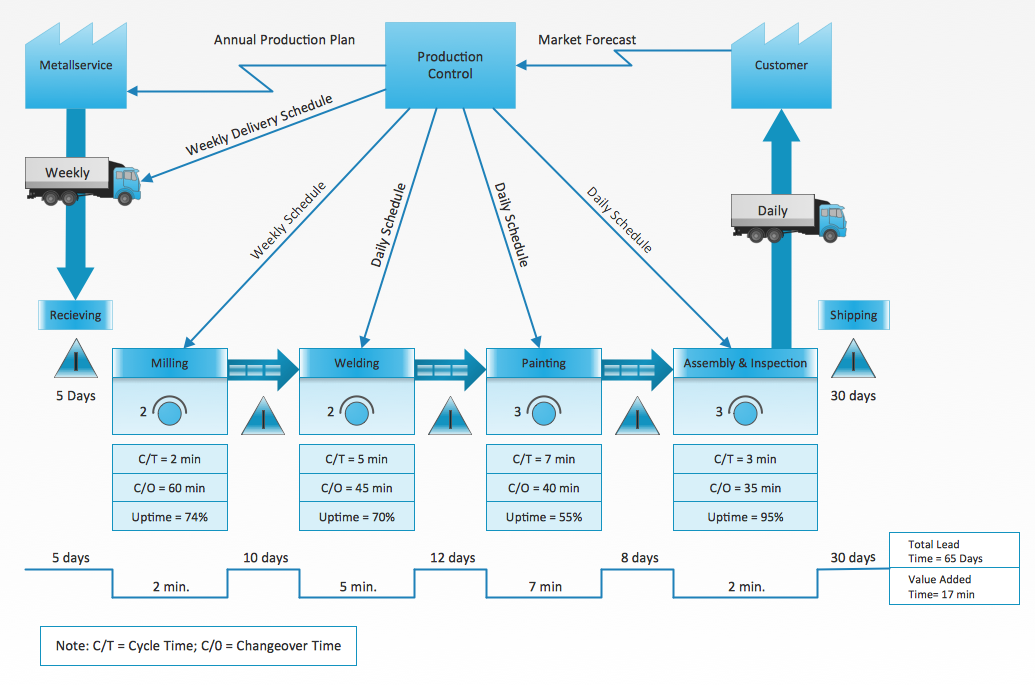

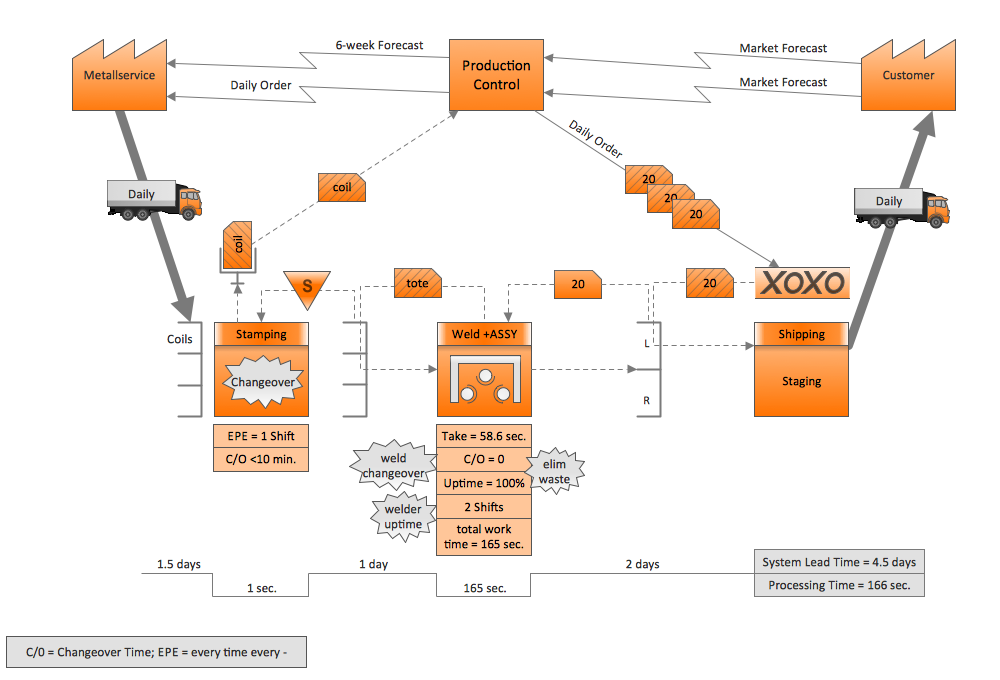

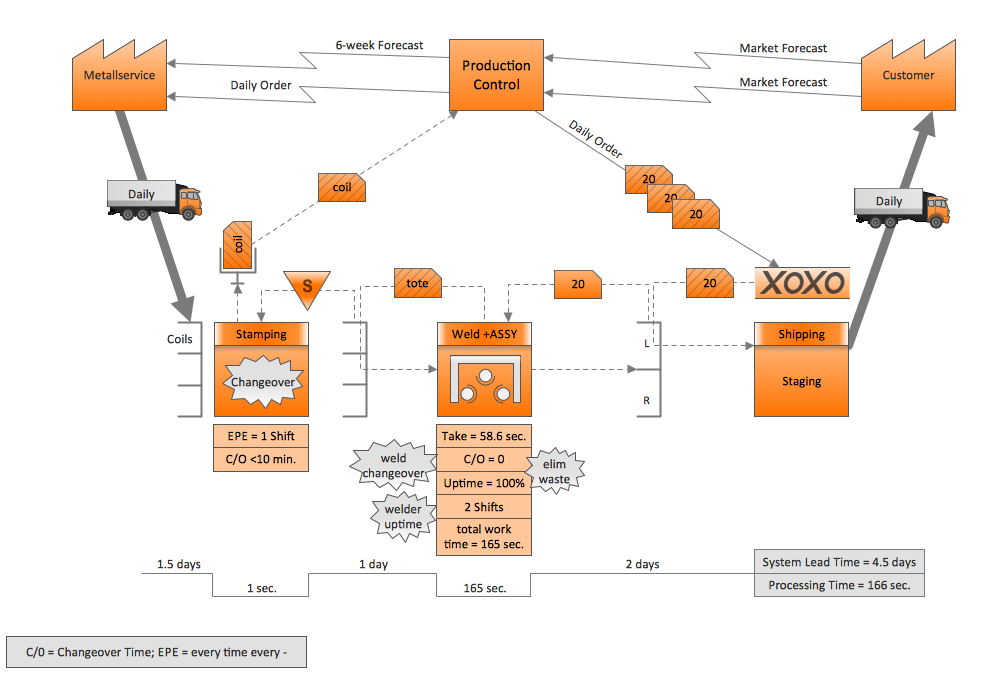

This sample Value Stream Map shows how customer value is created in the steps of manufacturing, production control, and shipping processes.

This VSM example was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

– Special type of flow chart that uses symbols known as "the language of Lean" to depict and improve the flow of inventory information. ...

Value Stream Mapping ...

Provide optimum value to the customer through a complete value creation process with minimum waste in:

– Design (concept to customer);

– Design (concept to customer);

– Build (order to delivery);

– Sustain (in-use through life cycle to service)." [courses.washington.edu/ ie337/ Value_ Stream_ Mapping.pdf]

This sample Value Stream Map shows how customer value is created in the steps of manufacturing, production control, and shipping processes.

This VSM example was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

"Value Stream Map (VSM)

1. A tool used to improve a process by identifying added value and eliminating waste.

2. A process map that follows the value creation process.

A. “strap yourself to the product (or service) and see where you go”

3. A process map with data added.

A. Times: processing, wait, cycle.

B. Quality: number of rejects.

C. Inventory.

D. Resources.

1) Number of people.

2) Space.

3) Distance traveled.

E. Whatever else is useful for analyzing the process." [ocw.mit.edu/ courses/ aeronautics-and-astronautics/ 16-660j-introduction-to-lean-six-sigma-methods-january-iap-2012/ lecture-notes/ MIT16_ 660JIAP12_ 1-6.pdf]

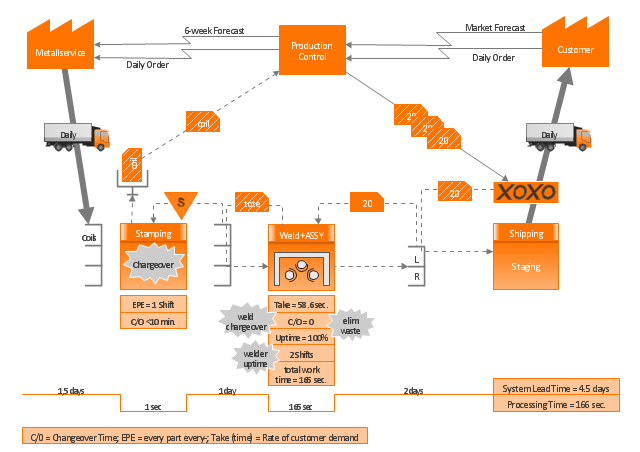

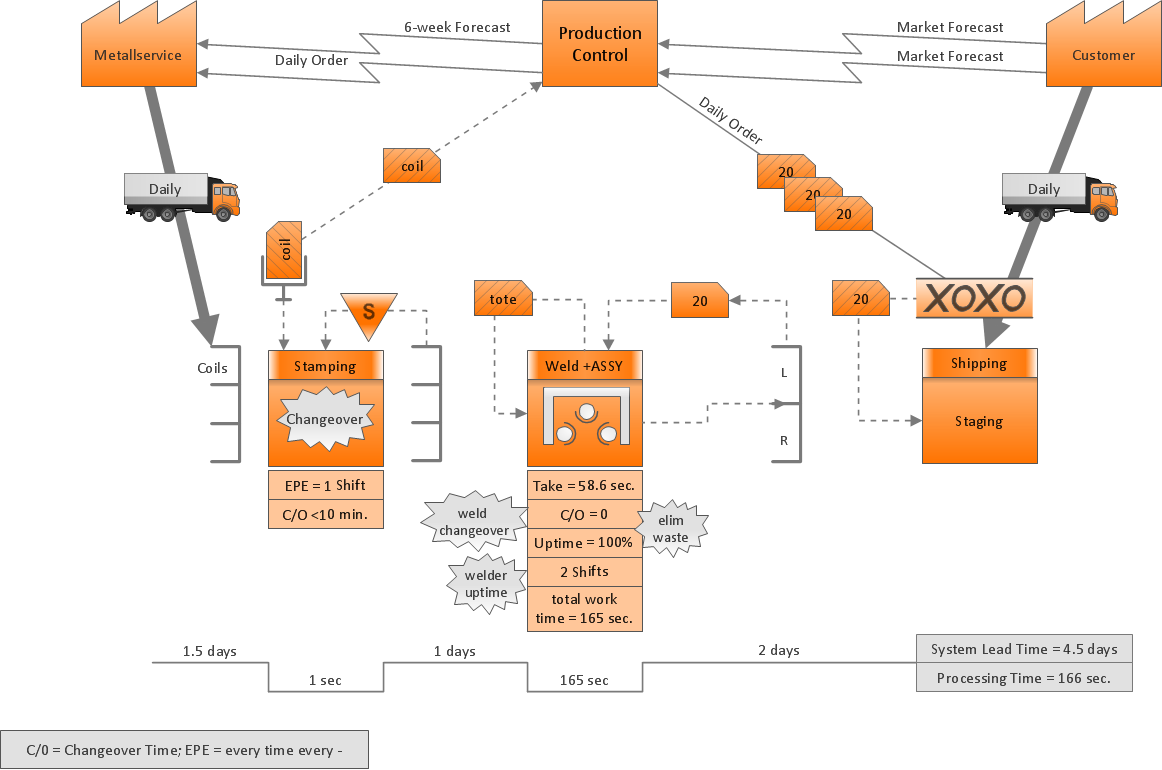

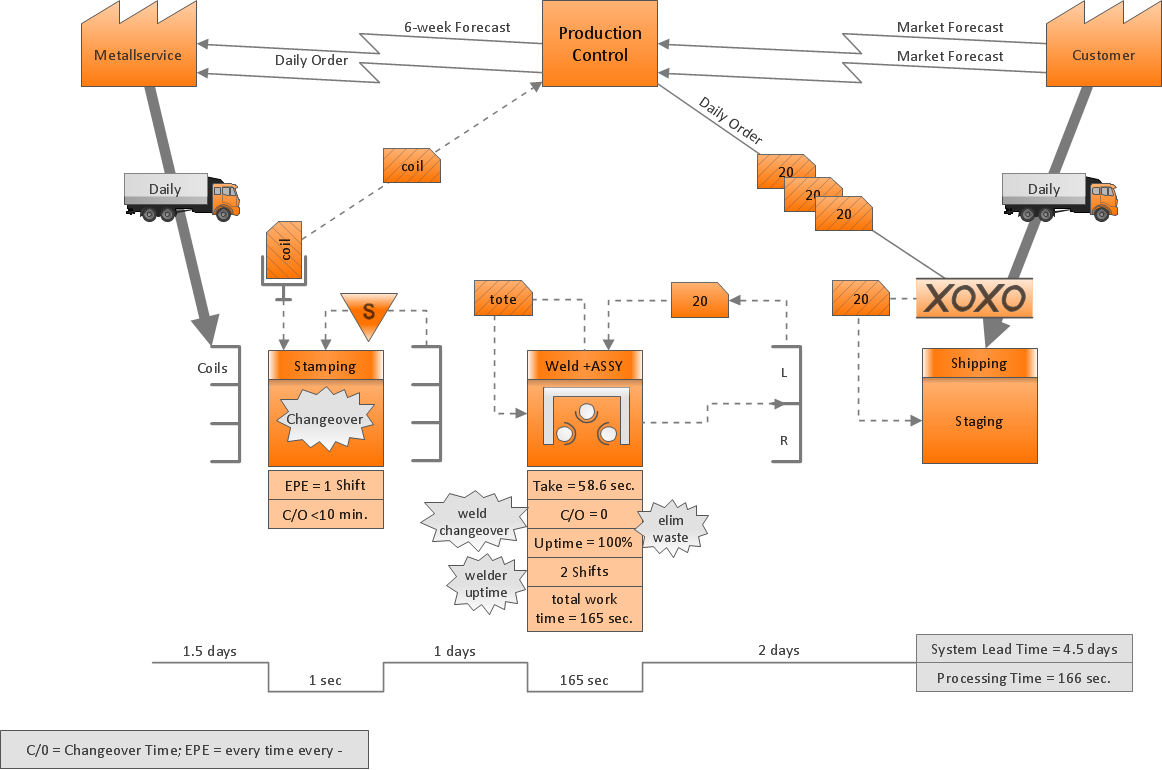

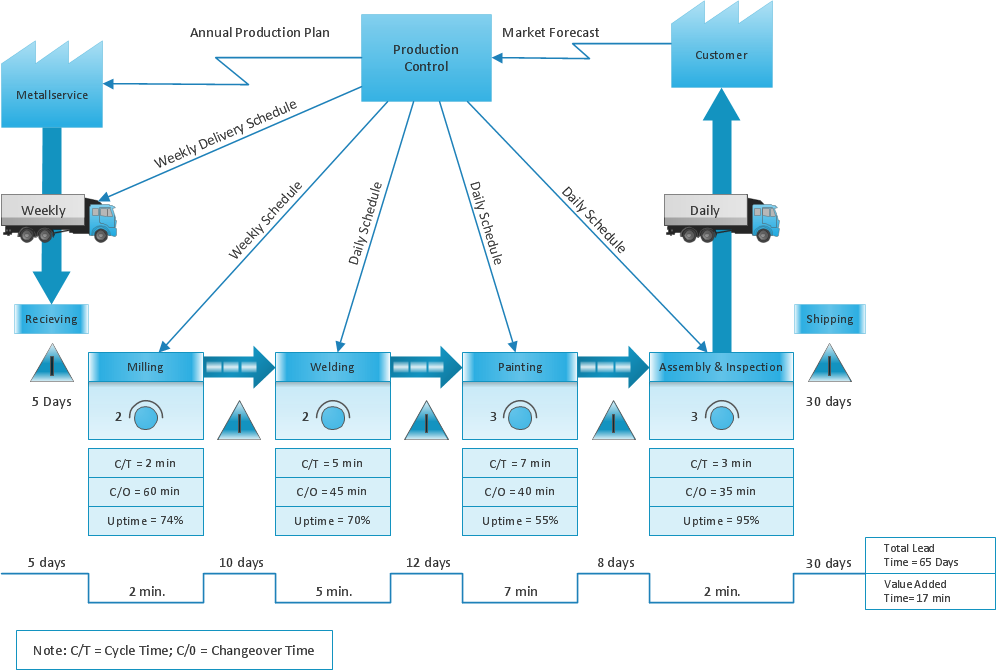

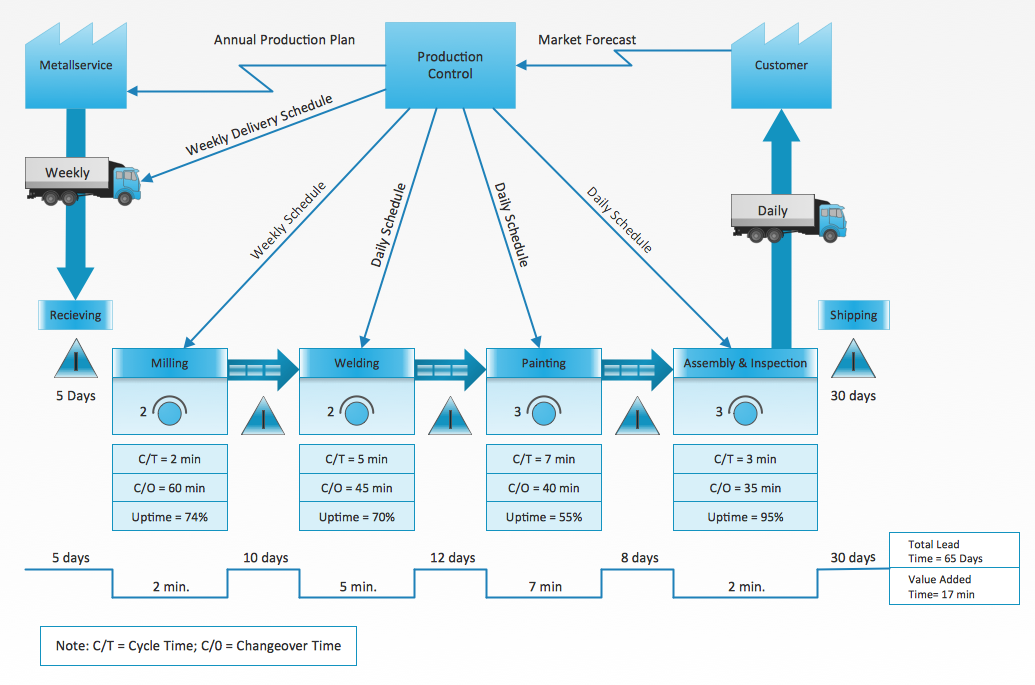

This sample VSM flowchart shows the value stream in a manufacturing, production control and shipping processes.

This value stream mapping diagram example was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

1. A tool used to improve a process by identifying added value and eliminating waste.

2. A process map that follows the value creation process.

A. “strap yourself to the product (or service) and see where you go”

3. A process map with data added.

A. Times: processing, wait, cycle.

B. Quality: number of rejects.

C. Inventory.

D. Resources.

1) Number of people.

2) Space.

3) Distance traveled.

E. Whatever else is useful for analyzing the process." [ocw.mit.edu/ courses/ aeronautics-and-astronautics/ 16-660j-introduction-to-lean-six-sigma-methods-january-iap-2012/ lecture-notes/ MIT16_ 660JIAP12_ 1-6.pdf]

This sample VSM flowchart shows the value stream in a manufacturing, production control and shipping processes.

This value stream mapping diagram example was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

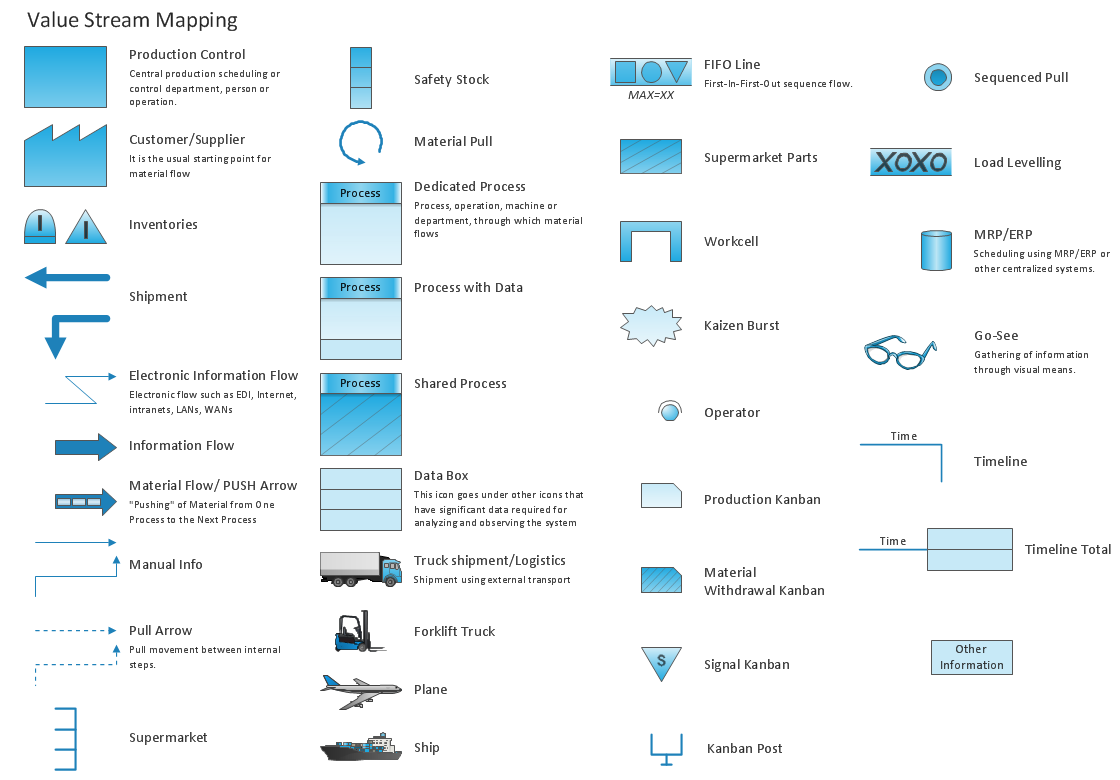

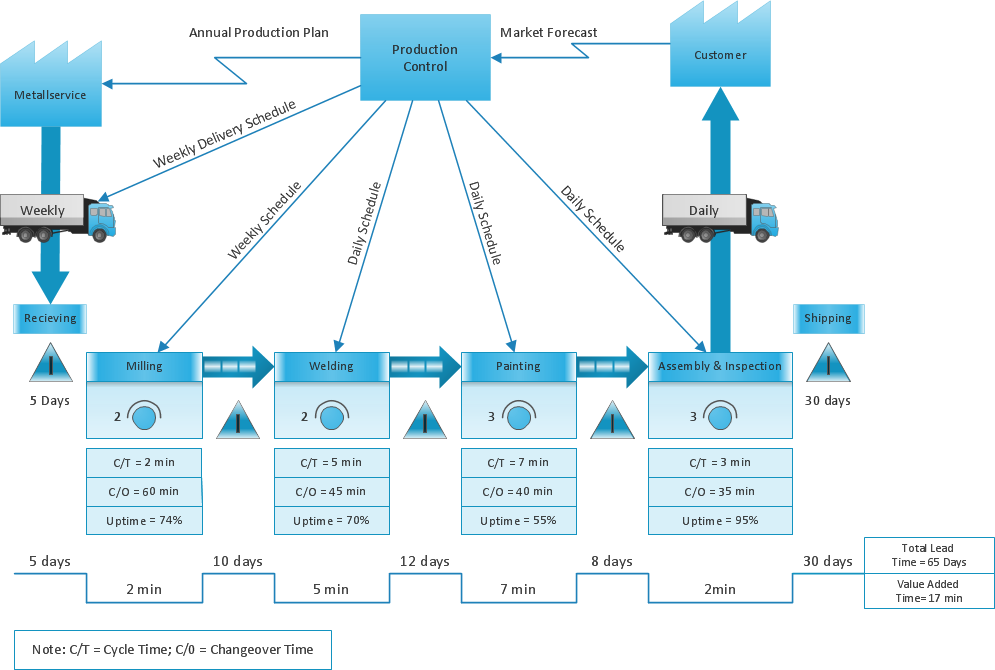

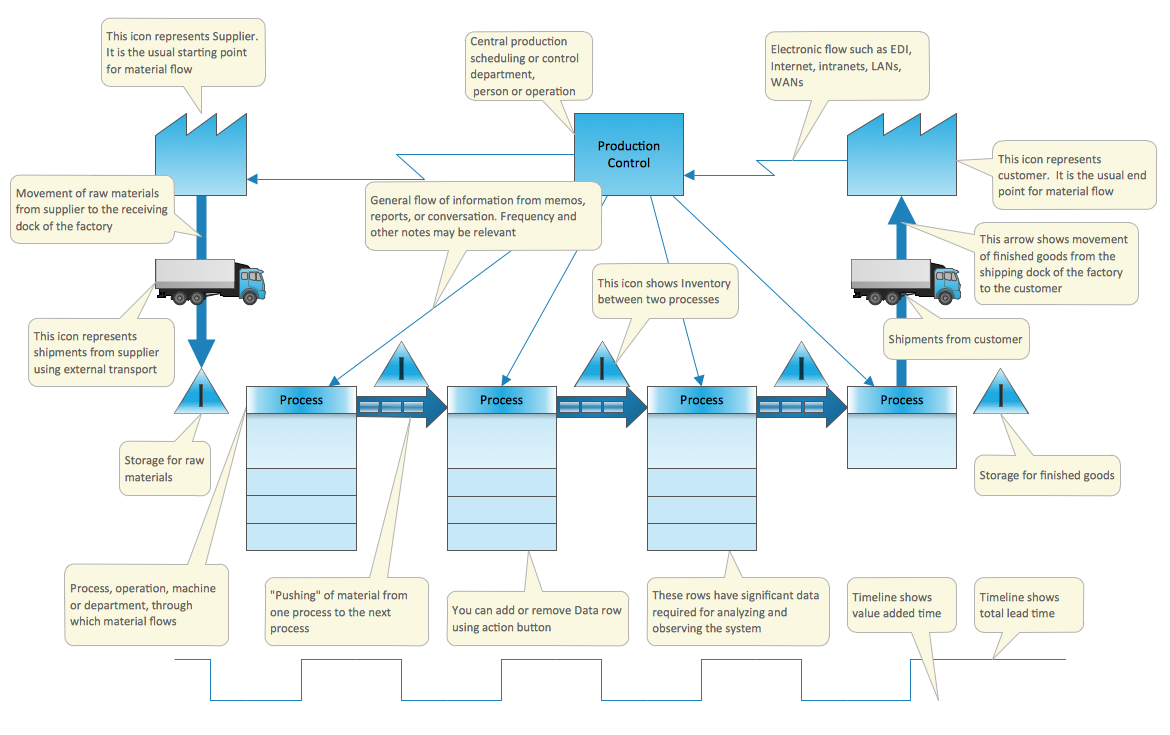

Value Stream Mapping Symbols

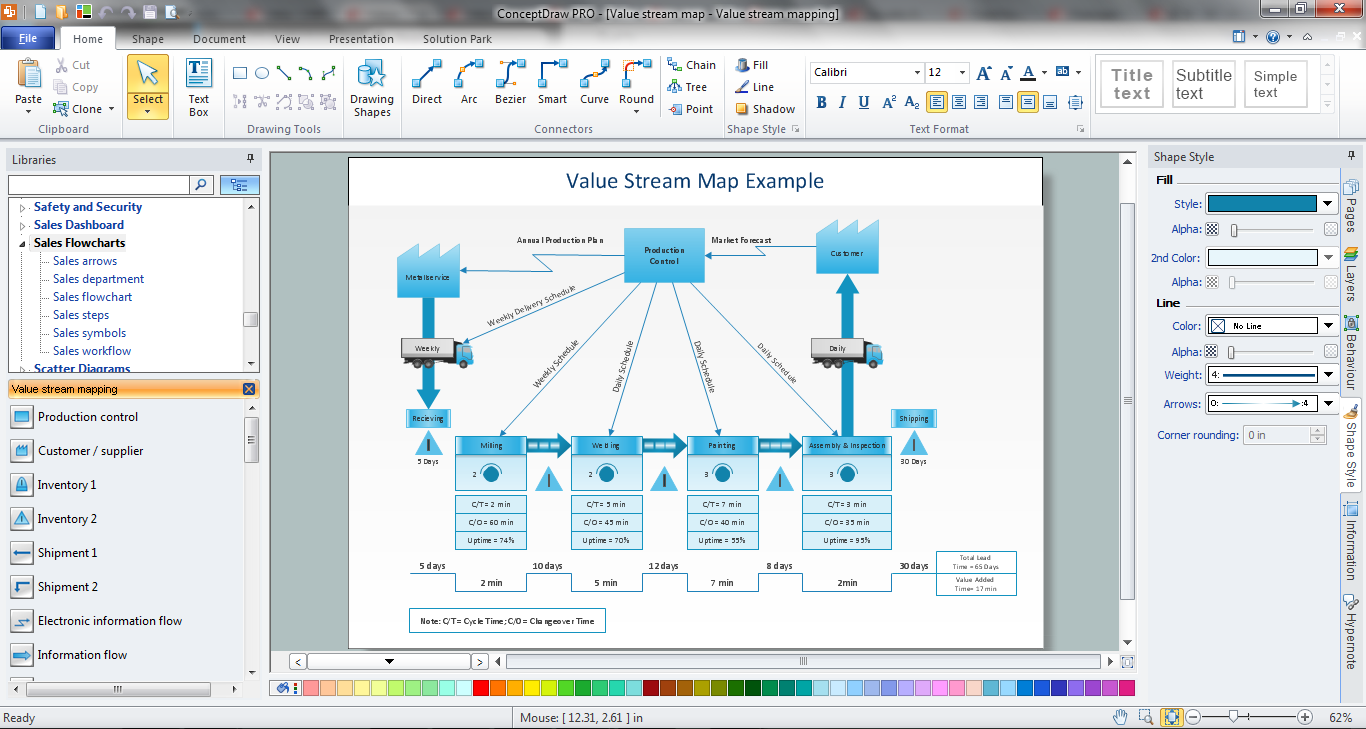

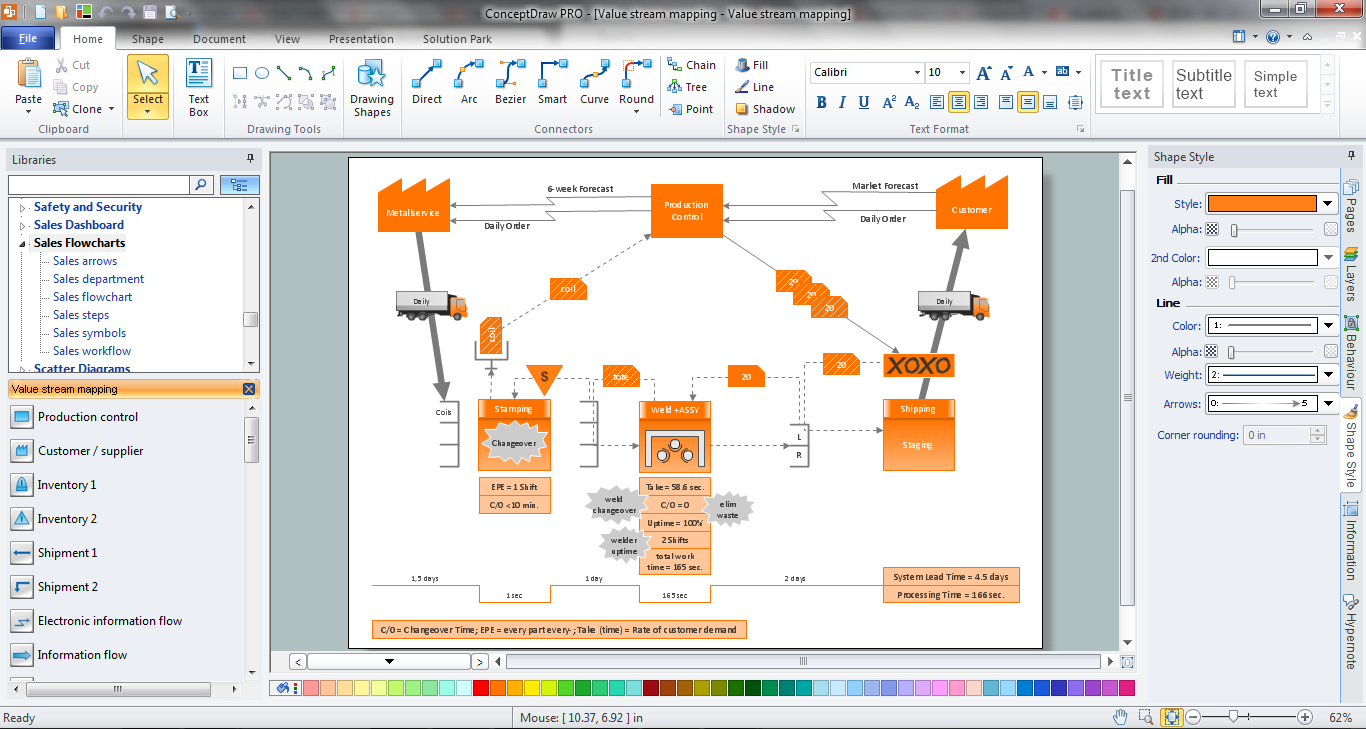

VSM symbols are the best for a production process designing. The entire Value Stream Mapping method uses a graphical representation of the manufacturing process, factors' pros and cons, that all stakeholders can easily understand. Value Stream Mapping is a graphical technique that provides possibilities to improve analysis of a manufacturing process, at the stage of the transferring information or materials that required to deliver a product or service to the customer.Lean Value Stream Map

Lean Manufacturing tool is a new Value Stream Mapping solution found in the ConceptDraw Solution Park.

Value Stream Mapping

Value Stream Mapping

Value stream mapping solution extends ConceptDraw DIAGRAM software with templates, samples and vector stencils for drawing the Value Stream Maps (VSM) in lean manufacturing practice.

Value Stream Mapping for the Lean Office

Value Stream Mapping for the lean office is a tool that uses a flow diagram to document in great detail every step of a manufacturing process.Value-Stream Mapping for Manufacturing

Create value stream maps - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.What is Value Stream Mapping?

Value stream maps (VSM) are an essential tool for organizations applying Lean methods.The vector stencils library "Value stream mapping" contains 43 VSM symbols.

Use it for drawing value stream maps in the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

www.conceptdraw.com/ solution-park/ business-value-stream-mapping

Use it for drawing value stream maps in the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

www.conceptdraw.com/ solution-park/ business-value-stream-mapping

Value Stream Diagram

The new Value Stream Mapping solution found in the ConceptDraw Solution Park continues to extend the range of ConceptDraw DIAGRAM into a business graphics tool.Value Stream Management

The Value Stream Mapping solution found in the ConceptDraw Solution Park continues to extend the range of ConceptDraw DIAGRAM into a business graphics tool that can be used to document processes in any organization.Value Stream Mapping Template

Use ConceptDraw DIAGRAM extended with Value Stream Mapping solution for document processes with professional designed Value Stream Mapping template.Quality Engineering Diagrams

Create Quality Engineering Diagrams (value stream maps) - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.Sections of the Value Stream Map

The Value Stream Mapping solution extends ConceptDraw DIAGRAM software with a new library that contain vector objects, samples and templates.Value Stream Mapping Software

ConceptDraw DIAGRAM is a best Value Stream Mapping software. The graphical representation of a process is a powerful tool that helps in the diagnosis of process efficiency and allows companies to develop improved processes. The new Value Stream Mapping solution found in the ConceptDraw Solution Park continues to extend the range of ConceptDraw DIAGRAM into a business graphics tool that can be used to document processes in any organization.Value Stream Mapping Examples

ConceptDraw DIAGRAM diagramming and vector drawing software supplied with Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park is ideal for drawing Value Stream Maps and includes variety of value stream mapping examples.VSM

Value stream mapping is a lean-management method for analyzing the current state and designing a future state for the series of events that take a product or service from its beginning through to the customer. ConceptDraw DIAGRAM diagramming and vector drawing software extended with Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park is effective for implementation a value stream mapping (VSM) process and for creating Value Stream Maps.Value Stream Mapping

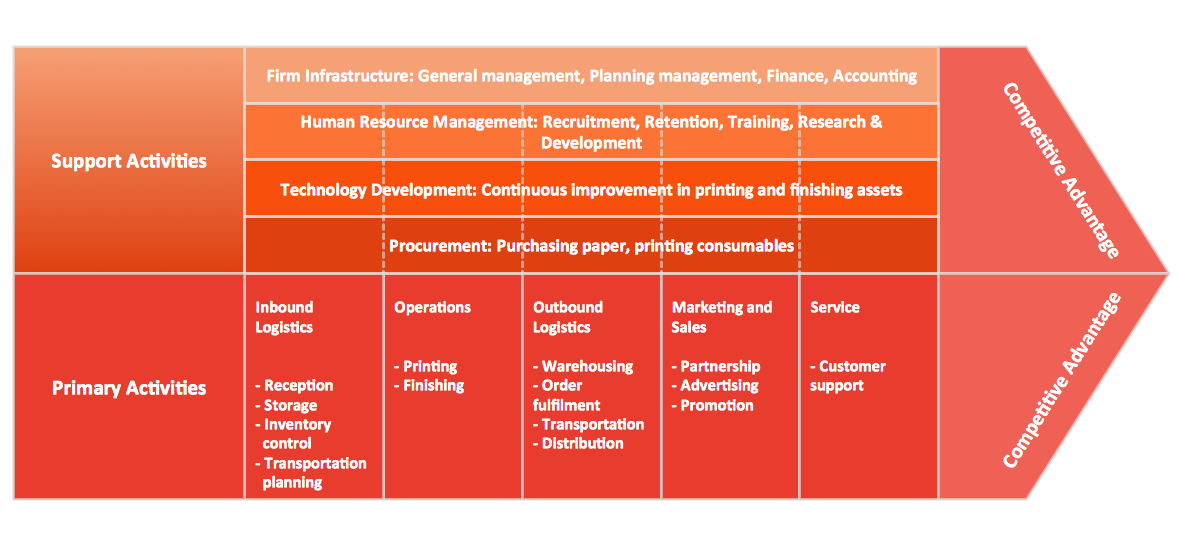

Use ConceptDraw Value Stream Maps (VSM) visualization for a manufacturing plant the material and information flow required to deliver a product/service to customers. The new Value Stream Mapping solution found in the ConceptDraw Solution Park continues to extend the range of ConceptDraw DIAGRAM into a business graphics tool that can be used to document processes in any organization.Porter's Value Chain

ConceptDraw DIAGRAM diagramming and vector drawing software offers you the Matrices Solution from the Marketing Area with extensive drawing tools for creating the Porter's Value Chain diagrams.

Business Process Mapping

Business Process Mapping

The Business Process Mapping solution for ConceptDraw DIAGRAM is for users involved in process mapping and creating SIPOC diagrams.

- Value stream mapping diagram

- What is Value Stream Mapping ?

- Value stream map - Template | Design elements - Value stream ...

- Value stream mapping diagram | How to Create a VSM Diagram ...

- Value Stream Mapping

- Value Stream Mapping Template

- Basic Diagramming | Value stream map - Template | UML ...

- Order processing - Cross-functional flowchart | Order processing ...

- Logistics Flow Charts | Value stream mapping - Vector stencils ...

- Value stream mapping - Vector stencils library | Design elements ...

- Value Stream Mapping Symbols | Process Flowchart | EPC ...

- Plant Layout Plans | Value Stream Mapping | Sample Of Receiving ...

- Value Stream Mapping | ConceptDraw Arrows10 Technology ...

- Inventory Performance Dynamics Dashboard | Value stream ...

- Conceptual diagram of the Kanban System | Value stream mapping ...

- Swim lane diagram - Payroll process mapping | Value stream ...

- Value stream mapping - Vector stencils library | Circuits and Logic ...

- Flow chart Example. Warehouse Flowchart | Value Stream Mapping ...

- Lean Manufacturing Diagrams | Value Stream Mapping | Types of ...

- Value Stream Mapping