Total Quality Management Value

The Total quality management (TQM) is an enterprise-wide method of continuous quality improvement of all organizational processes, including the enhancement of ability to deliver high-quality products and services to the customers. The TQM includes eight main elements, which have great value: customer-focused, process-centered, total employee involvement, integrated system, continual improvement, strategic and systematic approach, fact-based decision making, communications. ConceptDraw PRO diagramming and vector drawing software offers the Total Quality Management Diagram solution with effective drawing tools, predesigned vector elements, samples and templates that help easy design the Total Quality Management diagrams, TQM flowcharts and Mind Maps widely used in quality management projects to visualize the business processes and industrial processes for your organization, to demonstrate the quality control step-by-step in a visual manner, to compare visually the ideal and real stages of processes.TQM Diagram Tool

The Total Quality Management Diagram solution helps you and your organization visualize business and industrial processes. Create Total Quality Management diagrams for business process with ConceptDraw software.Seven Basic Tools of Quality - Fishbone Diagram

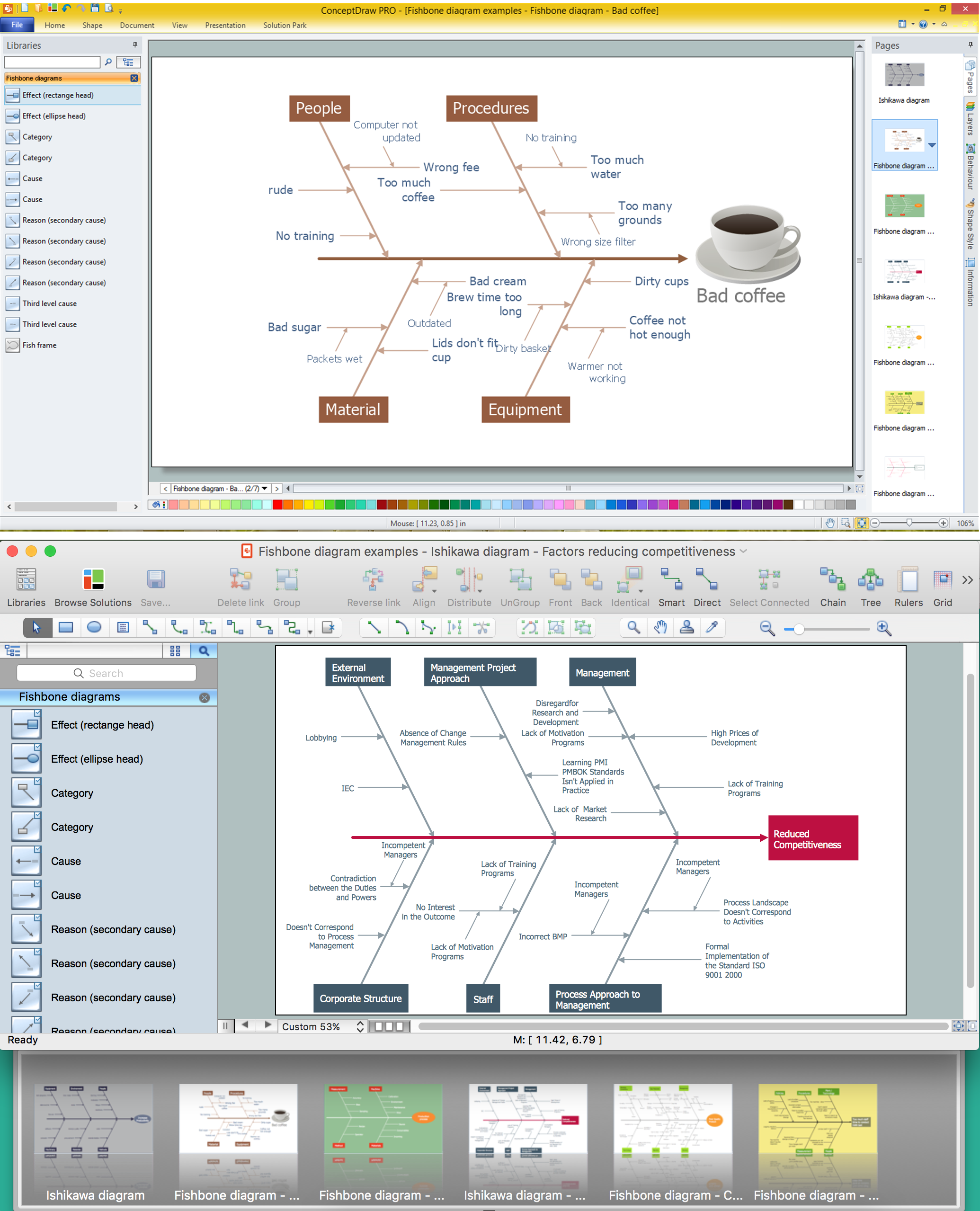

ConceptDraw PRO enhanced with Seven Basic Tools of Quality solution from the Quality area of ConceptDraw Solution Park is an ideal software for fast and easy drawing professional looking quality diagrams, including a Fishbone diagram.

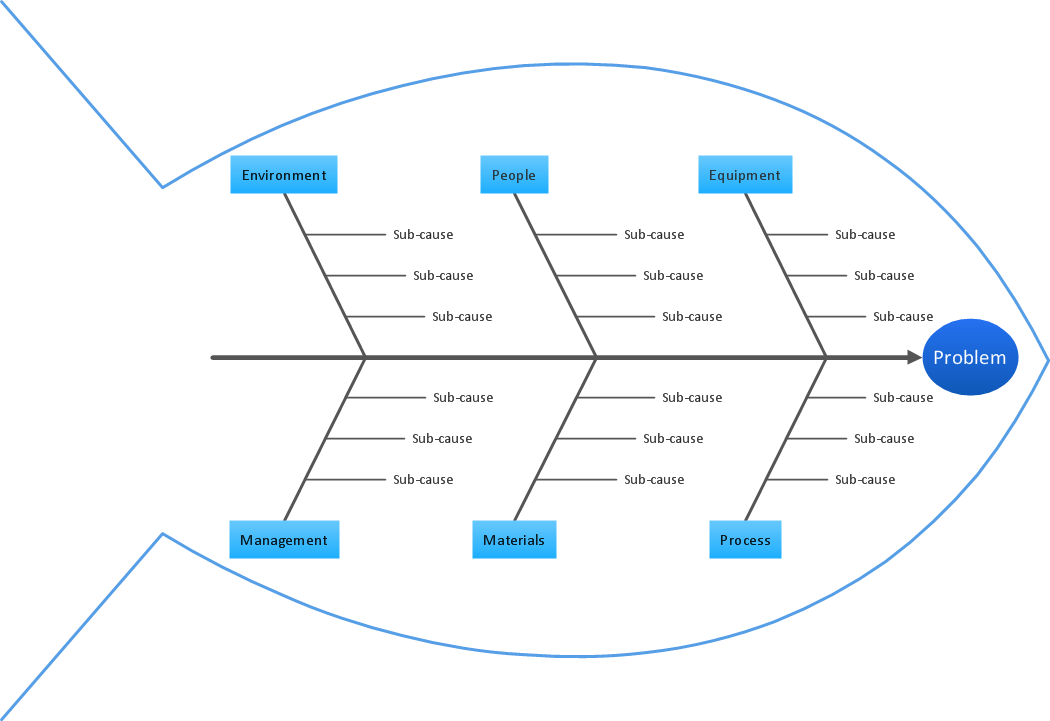

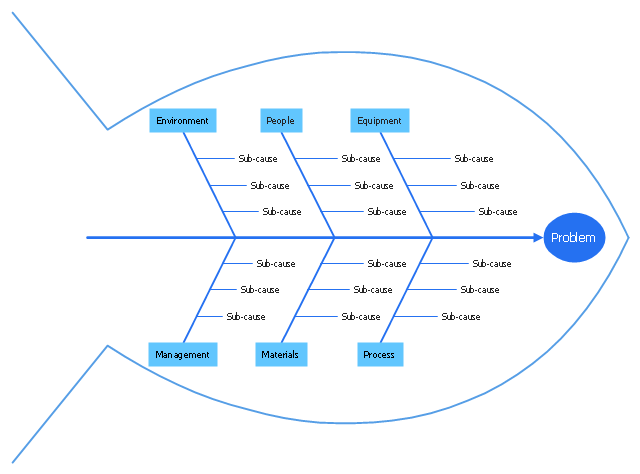

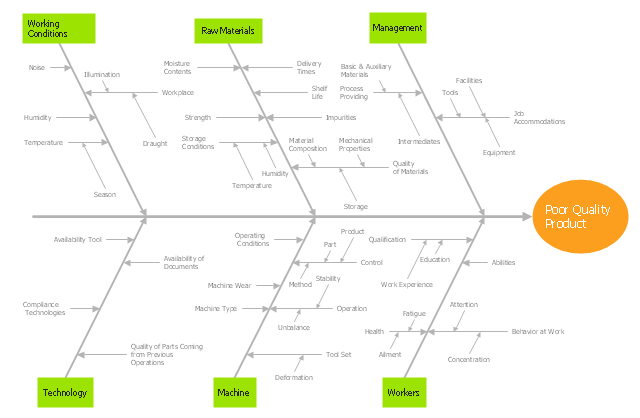

Fishbone Diagram

Fishbone Diagram

Fishbone Diagrams solution extends ConceptDraw PRO software with templates, samples and library of vector stencils for drawing the Ishikawa diagrams for cause and effect analysis.

Total Quality Management Business Diagram

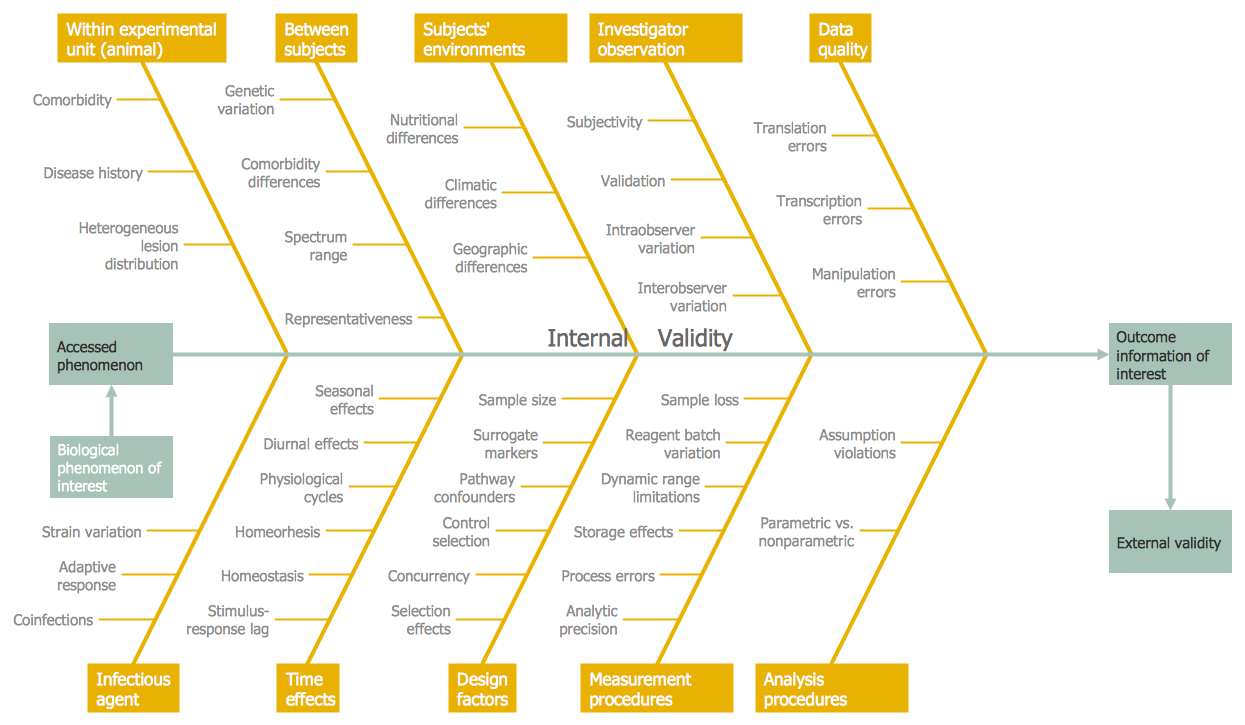

The Total Quality Management Diagram solution helps you and your organization visualize business and industrial processes. Create Total Quality Management diagrams for business process with ConceptDraw software."Common uses of the Ishikawa diagram are product design and quality defect prevention, to identify potential factors causing an overall effect. Each cause or reason for imperfection is a source of variation. Causes are usually grouped into major categories to identify these sources of variation. The categories typically include:

(1) People: Anyone involved with the process;

(2) Methods: How the process is performed and the specific requirements for doing it, such as policies, procedures, rules, regulations and laws;

(3) Machines: Any equipment, computers, tools, etc. required to accomplish the job;

(4) Materials: Raw materials, parts, pens, paper, etc. used to produce the final product;

(5) Measurements: Data generated from the process that are used to evaluate its quality;

(6) Environment: The conditions, such as location, time, temperature, and culture in which the process operates. ...

Ishikawa diagrams were popularized by Kaoru Ishikawa in the 1960s, who pioneered quality management processes in the Kawasaki shipyards, and in the process became one of the founding fathers of modern management.

The basic concept was first used in the 1920s, and is considered one of the seven basic tools of quality control." [Ishikawa diagram. Wikipedia]

This quality Ishikawa diagram (cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

(1) People: Anyone involved with the process;

(2) Methods: How the process is performed and the specific requirements for doing it, such as policies, procedures, rules, regulations and laws;

(3) Machines: Any equipment, computers, tools, etc. required to accomplish the job;

(4) Materials: Raw materials, parts, pens, paper, etc. used to produce the final product;

(5) Measurements: Data generated from the process that are used to evaluate its quality;

(6) Environment: The conditions, such as location, time, temperature, and culture in which the process operates. ...

Ishikawa diagrams were popularized by Kaoru Ishikawa in the 1960s, who pioneered quality management processes in the Kawasaki shipyards, and in the process became one of the founding fathers of modern management.

The basic concept was first used in the 1920s, and is considered one of the seven basic tools of quality control." [Ishikawa diagram. Wikipedia]

This quality Ishikawa diagram (cause and effect diagram) template is included in the Fishbone Diagram solution from the Management area of ConceptDraw Solution Park.

Using Fishbone Diagrams for Problem Solving

Problems are obstacles and challenges that one should overcome to reach the goal. They are an inseparable part of any business, and the success of an enterprise often depends on ability to solve all problems effectively. The process of problem solving often uses rational approach, helping to find a suitable solution. Using Fishbone Diagrams for Problem Solving is a productive and illustrative tool to identify the most important factors causing the trouble. ConceptDraw PRO extended with Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park is a powerful tool for problem solving with Fishbone Ishikawa diagram graphic method.Fishbone Diagram Example

Fishbone Diagram, also referred as Cause and Effect diagram or Ishikawa diagram, is a fault finding and problem solving tool. Construction of Ishikawa diagrams is quite complicated process and has a number of features. Fishbone Diagrams solution included to ConceptDraw Solution Park contains powerful drawing tools and a lot of examples, samples and templates. Each Fishbone diagram example is carefully thought-out by experts and is perfect source of inspiration for you.Fishbone Diagram Procedure

ConceptDraw PRO diagramming and vector drawing software enhanced with Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park gives the ability to draw Fishbone diagram, which identifies many possible causes for an effect for problem solving. Fishbone Diagram procedure of creation includes the set of steps easy for execution in ConceptDraw PRO.Cause and Effect Fishbone Diagram

Cause and Effect Fishbone Diagram is one of the popular productivity and management tools widely used in business organizations. It is also known as Fishbone Diagram, because it looks like a fish skeleton. Cause and Effect Diagram provides a structured way which helps to identify all possible causes of a problem. Cause and Effect Diagram can be applied anywhere where exists a causal relationship. Now the problem of complexity the Cause and Effect Fishbone Diagram creating is solved thanks to the ConceptDraw PRO diagramming and vector drawing software extended with Fishbone Diagrams solution from the Management area.Use a Fishbone Diagram to Attack Complex Problems

Any project is a complex system which rarely goes without some problems, even the most minor. But the success of the project mostly depends from the ability effectively solve appearing problems. There are many methods for problem solving, one of the most effective is the use a Fishbone diagram to attack complex problems. Use ConceptDraw PRO diagramming software with Fishbone Diagrams Solution to attack any complex problems with fishbone diagrams graphic method. Construct Fishbone diagram to help users brainstorm and break down a complex problem.Cause and Effect Diagrams

Cause and Effect Diagrams are designed to identify the potential factors that cause an overall effect. The causes are grouped into the categories, each cause is a source of variation. ConceptDraw PRO powerful diagramming and vector drawing software provides the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park that allows to design the Cause and Effect Diagrams quick, easy and effective.TQM Diagram Example

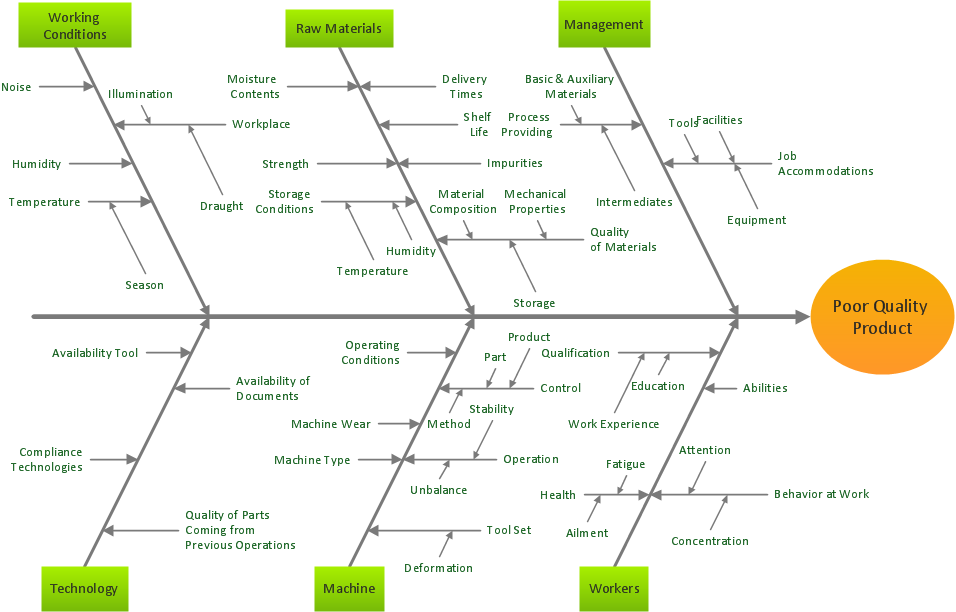

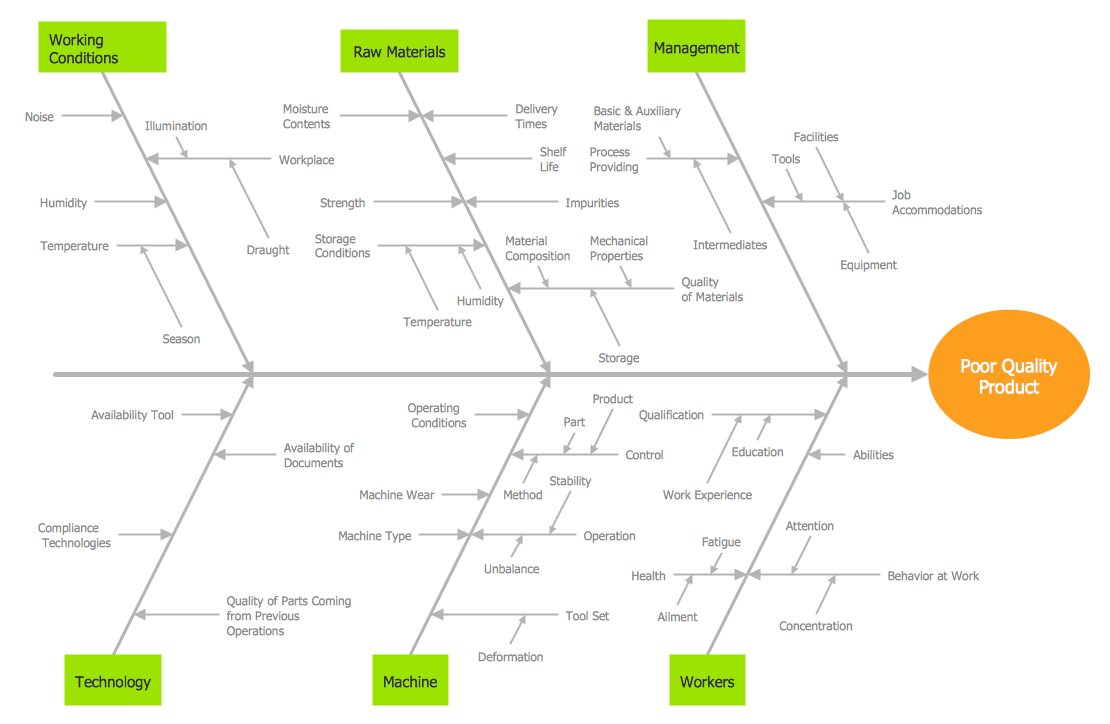

The Total Quality Management Diagram solution helps you and your organization visualize business and industrial processes. Create Total Quality Management diagrams for business process with ConceptDraw software."Ishikawa diagrams (also called fishbone diagrams, herringbone diagrams, cause-and-effect diagrams, or Fishikawa) are causal diagrams created by Kaoru Ishikawa (1968) that show the causes of a specific event. Common uses of the Ishikawa diagram are product design and quality defect prevention, to identify potential factors causing an overall effect. Each cause or reason for imperfection is a source of variation. Causes are usually grouped into major categories to identify these sources of variation. The categories typically include:

- People: Anyone involved with the process

- Methods: How the process is performed and the specific requirements for doing it, such as policies, procedures, rules, regulations and laws

- Machines: Any equipment, computers, tools, etc. required to accomplish the job

- Materials: Raw materials, parts, pens, paper, etc. used to produce the final product

- Measurements: Data generated from the process that are used to evaluate its quality

- Environment: The conditions, such as location, time, temperature, and culture in which the process operates" [Ishikawa diagram. Wikipedia]

The fishbone diagram example "Causes of low-quality output" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park.

- People: Anyone involved with the process

- Methods: How the process is performed and the specific requirements for doing it, such as policies, procedures, rules, regulations and laws

- Machines: Any equipment, computers, tools, etc. required to accomplish the job

- Materials: Raw materials, parts, pens, paper, etc. used to produce the final product

- Measurements: Data generated from the process that are used to evaluate its quality

- Environment: The conditions, such as location, time, temperature, and culture in which the process operates" [Ishikawa diagram. Wikipedia]

The fishbone diagram example "Causes of low-quality output" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park.

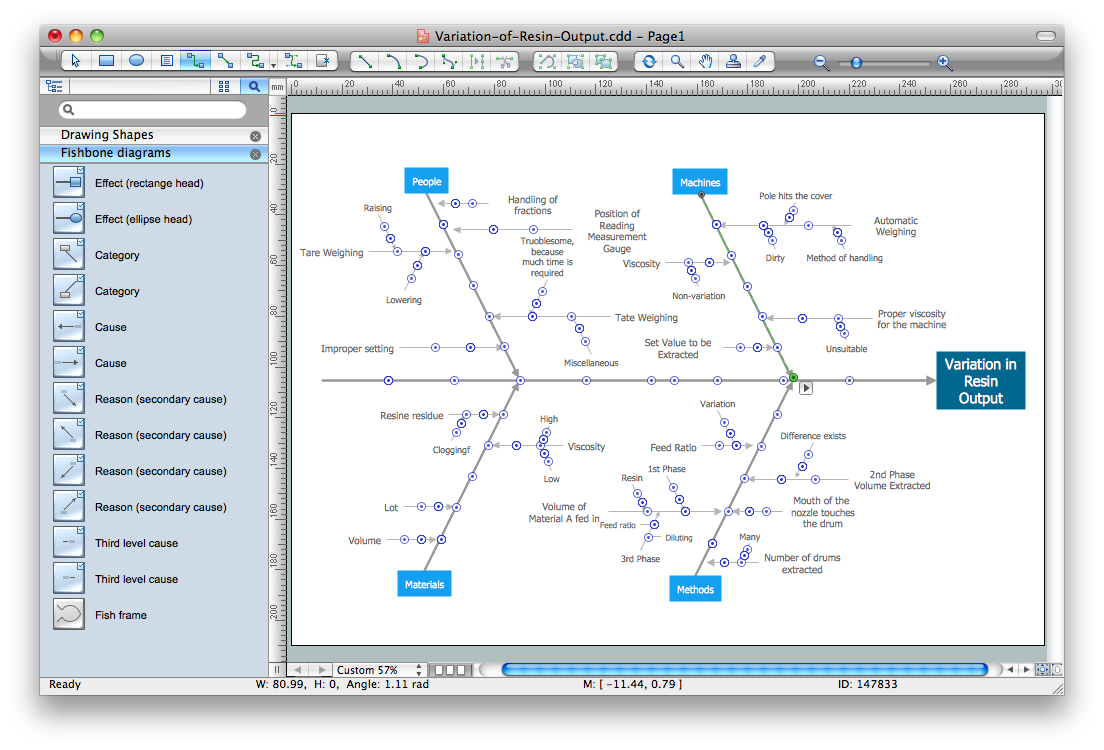

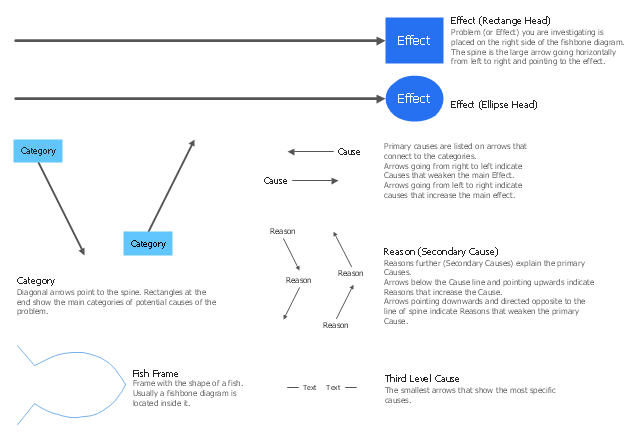

The library of vector stencils "Fishbone diagrams" contains 13 symbols for drawing the Ishikawa diagrams using the ConceptDraw PRO diagramming and vector drawing software.

"Ishikawa diagrams were popularized by Kaoru Ishikawa in the 1960s, who pioneered quality management processes in the Kawasaki shipyards, and in the process became one of the founding fathers of modern management.

The basic concept was first used in the 1920s, and is considered one of the seven basic tools of quality control. It is known as a fishbone diagram because of its shape, similar to the side view of a fish skeleton." [Ishikawa diagram. Wikipedia]

"The Seven Basic Tools of Quality is a designation given to a fixed set of graphical techniques identified as being most helpful in troubleshooting issues related to quality. They are called basic because they are suitable for people with little formal training in statistics and because they can be used to solve the vast majority of quality-related issues.

The seven tools are:

(1) Cause-and-effect diagram (also known as the "fishbone" or Ishikawa diagram);

(2) Check sheet;

(3) Control chart;

(4) Histogram;

(5) Pareto chart;

(6) Scatter diagram;

(7) Stratification (alternately, flow chart or run chart)." [Seven Basic Tools of Quality. Wikipedia]

The example "Design elements - Fishbone diagram" is included in the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park.

"Ishikawa diagrams were popularized by Kaoru Ishikawa in the 1960s, who pioneered quality management processes in the Kawasaki shipyards, and in the process became one of the founding fathers of modern management.

The basic concept was first used in the 1920s, and is considered one of the seven basic tools of quality control. It is known as a fishbone diagram because of its shape, similar to the side view of a fish skeleton." [Ishikawa diagram. Wikipedia]

"The Seven Basic Tools of Quality is a designation given to a fixed set of graphical techniques identified as being most helpful in troubleshooting issues related to quality. They are called basic because they are suitable for people with little formal training in statistics and because they can be used to solve the vast majority of quality-related issues.

The seven tools are:

(1) Cause-and-effect diagram (also known as the "fishbone" or Ishikawa diagram);

(2) Check sheet;

(3) Control chart;

(4) Histogram;

(5) Pareto chart;

(6) Scatter diagram;

(7) Stratification (alternately, flow chart or run chart)." [Seven Basic Tools of Quality. Wikipedia]

The example "Design elements - Fishbone diagram" is included in the Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park.

- Fishbone Diagram Poor Quality Of Product

- Fishbone Diagram | Seven Basic Tools of Quality - Fishbone ...

- Cause and Effect Analysis - Fishbone Diagrams for Problem Solving ...

- Fishbone Diagram Causes Of Low Quality Output

- Total Quality Management Value | Fishbone Diagram | Fishbone ...

- Fishbone Quality

- Fishbone Diagram | Quality fishbone diagram template | Fishbone ...

- Cause and Effect Analysis - Fishbone Diagrams for Problem Solving ...

- Manufacturing 8 Ms fishbone diagram - Template | Business ...

- Cause And Effect Diagram For Poor Quality Product

- Draw Fishbone Diagram on MAC Software | Total Quality ...

- Fishbone Diagrams | Total Quality Management Business Diagram ...

- PROBLEM ANALYSIS. Root Cause Analysis Tree Diagram | Root ...

- Ishikawa Diagram | Total Quality Management Value | Using ...

- Fishbone diagram - Causes of low- quality output | Fishbone ...

- Total Quality Management Value | Use a Fishbone Diagram to ...

- Fish Bone Diagram Production Tool

- Fishbone Diagram | Total Quality Management Business Diagram ...

- Process Flowchart | 4 Ms fishbone diagram - Production process ...

- Fishbone Diagram | Cause and Effect Analysis ( Fishbone Diagrams ...